Ventilated Roof Apparatus and Method

a technology for ventilating roofs and roofs, applied in ventilation systems, lighting and heating apparatuses, heating types, etc., can solve the problems of inadequate ventilation, air will take the flow path of low resistance, etc., and achieve adequate ventilation, low permeability, and easy adjustment of resistance to air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

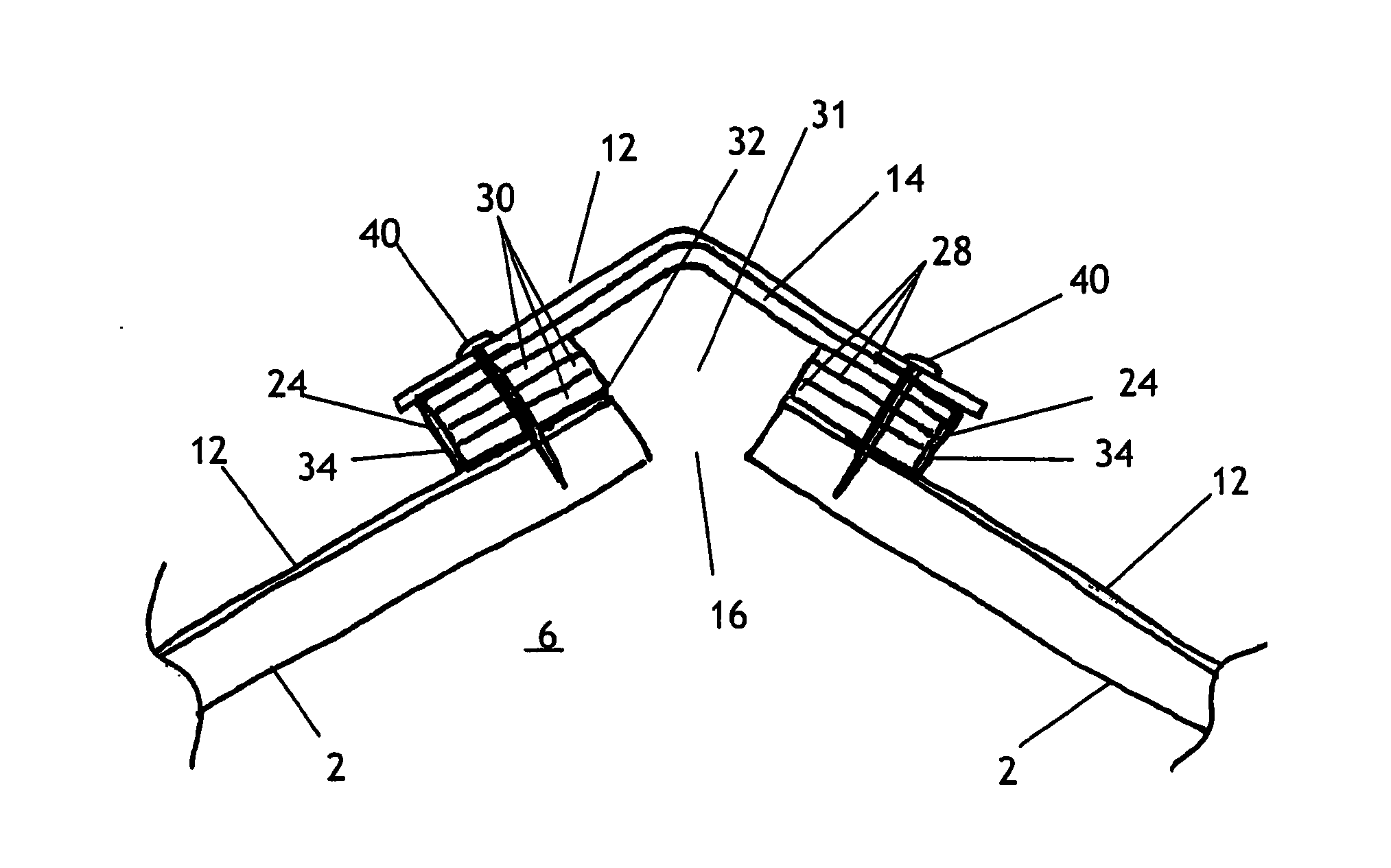

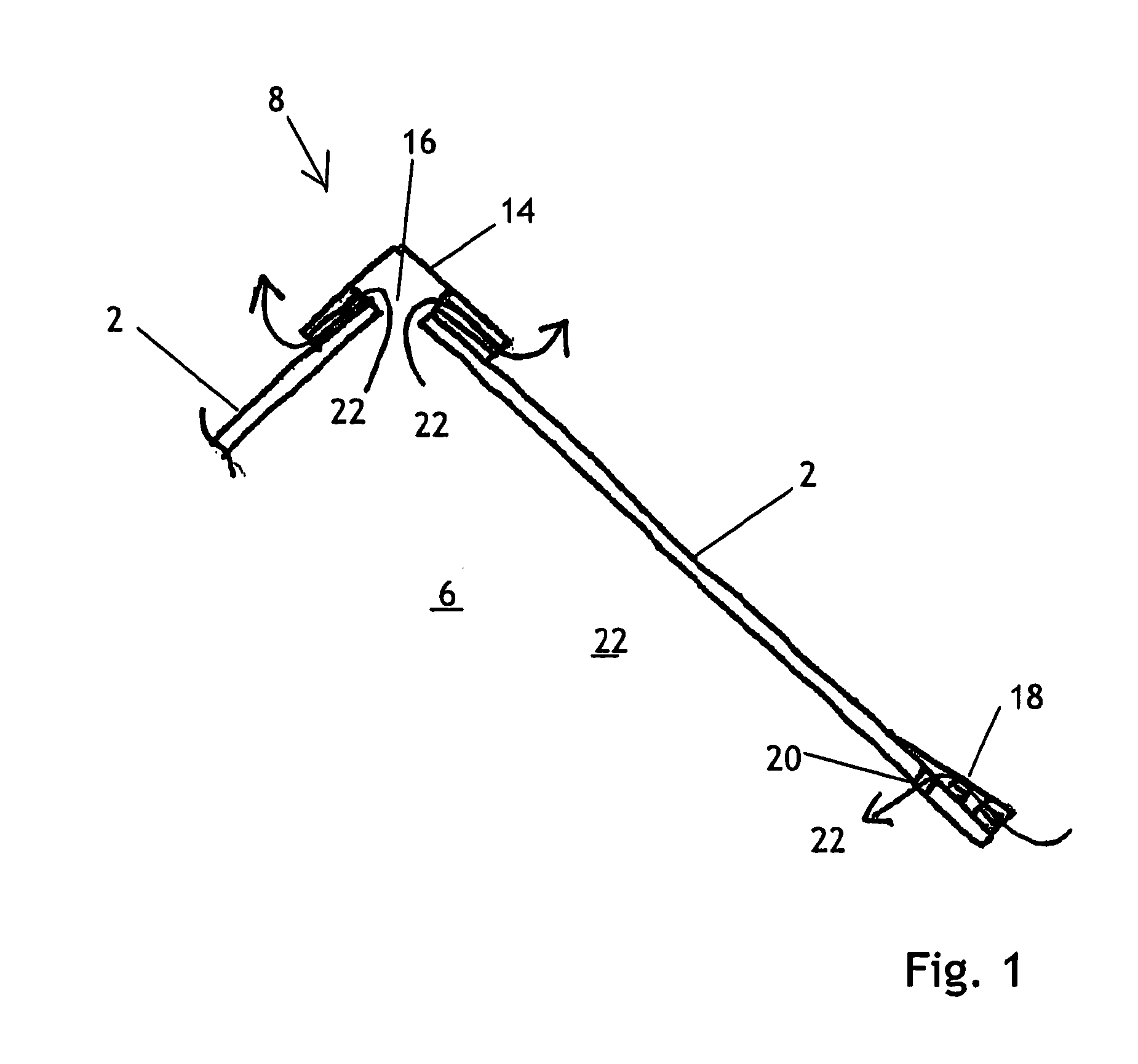

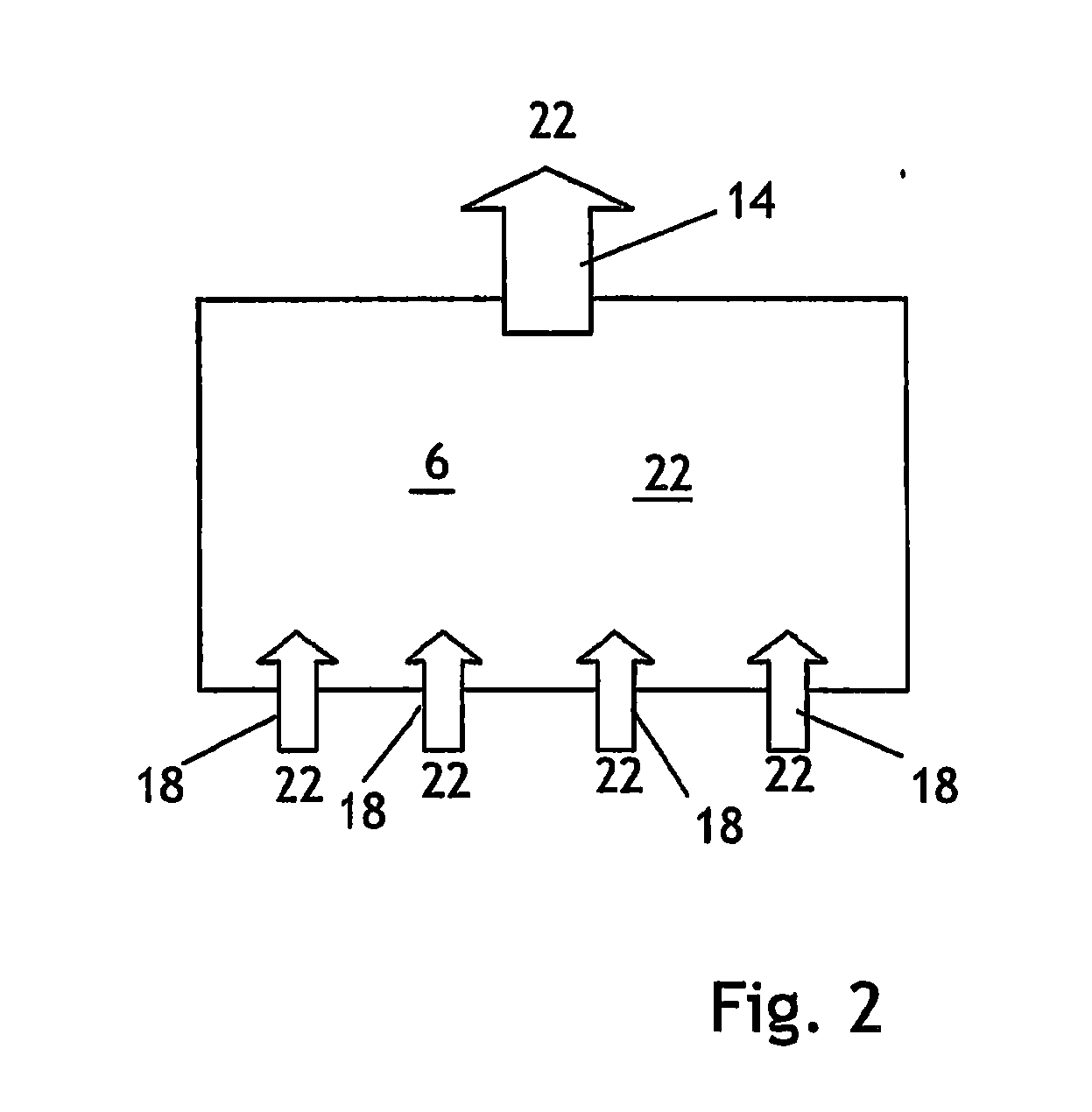

[0041]The invention is an apparatus and method for ventilating an attic space or other area under a roof. As illustrated by FIGS. 1 and 7 through 10, a roof deck 2 covers a structure 4. The structure 4 features an attic space 6 beneath the roof deck 2. As used in this document, the term ‘attic space’ also includes any area under a roof, such as the space between the ceiling and a roof deck 2 of a room having a cathedral ceiling. The roof deck 2 is pitched as illustrated by FIGS. 1 and 7 through 10, meaning that the roof deck 2 defines an adequate angle with the horizontal to allow the use of shingles 12. The roof deck 2 is composed of any suitable planar material, such as plywood or metal sheets. The roof deck 2 defines a ridge 8 at its highest location and an eave 10 at a location lower than the ridge 8.

[0042]As illustrated by FIGS. 1, 3, 4, 9 and 10, the roof includes a ridge vent 14 covering a roof deck ridge vent opening 16 located at the ridge 8 of the roof deck 2. The roof als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com