Cooling system for cooling of at least one circulating fluid, and a machine comprising the cooling system

a cooling system and circulating fluid technology, applied in the direction of engine cooling apparatus, stationary conduit assembly, lighting and heating apparatus, etc., can solve the problems of deteriorating system efficiency and increasing the risk of breakdowns, and achieve satisfactory air flow through the unit, facilitate service and cleaning, and improve the effect of cooling system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

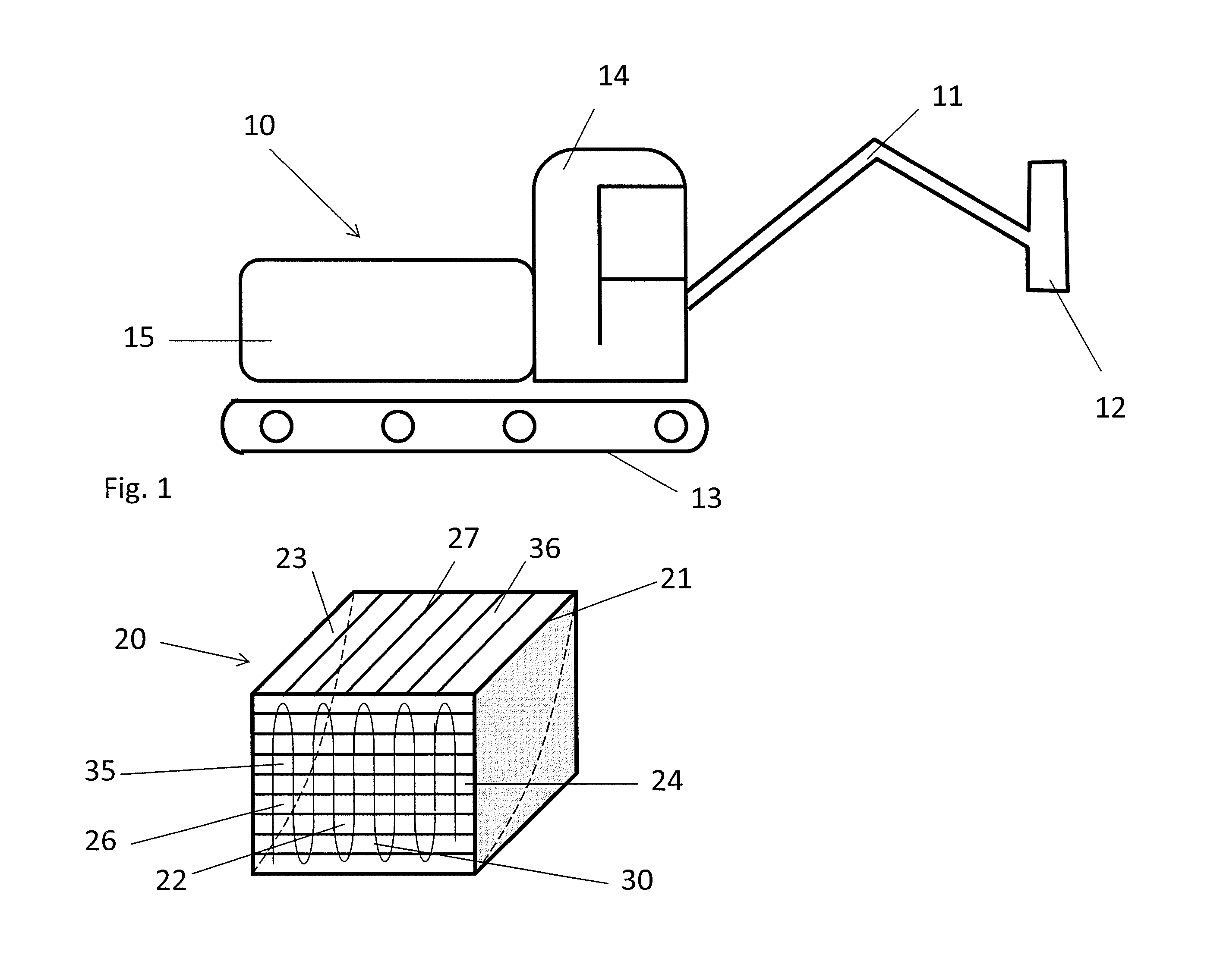

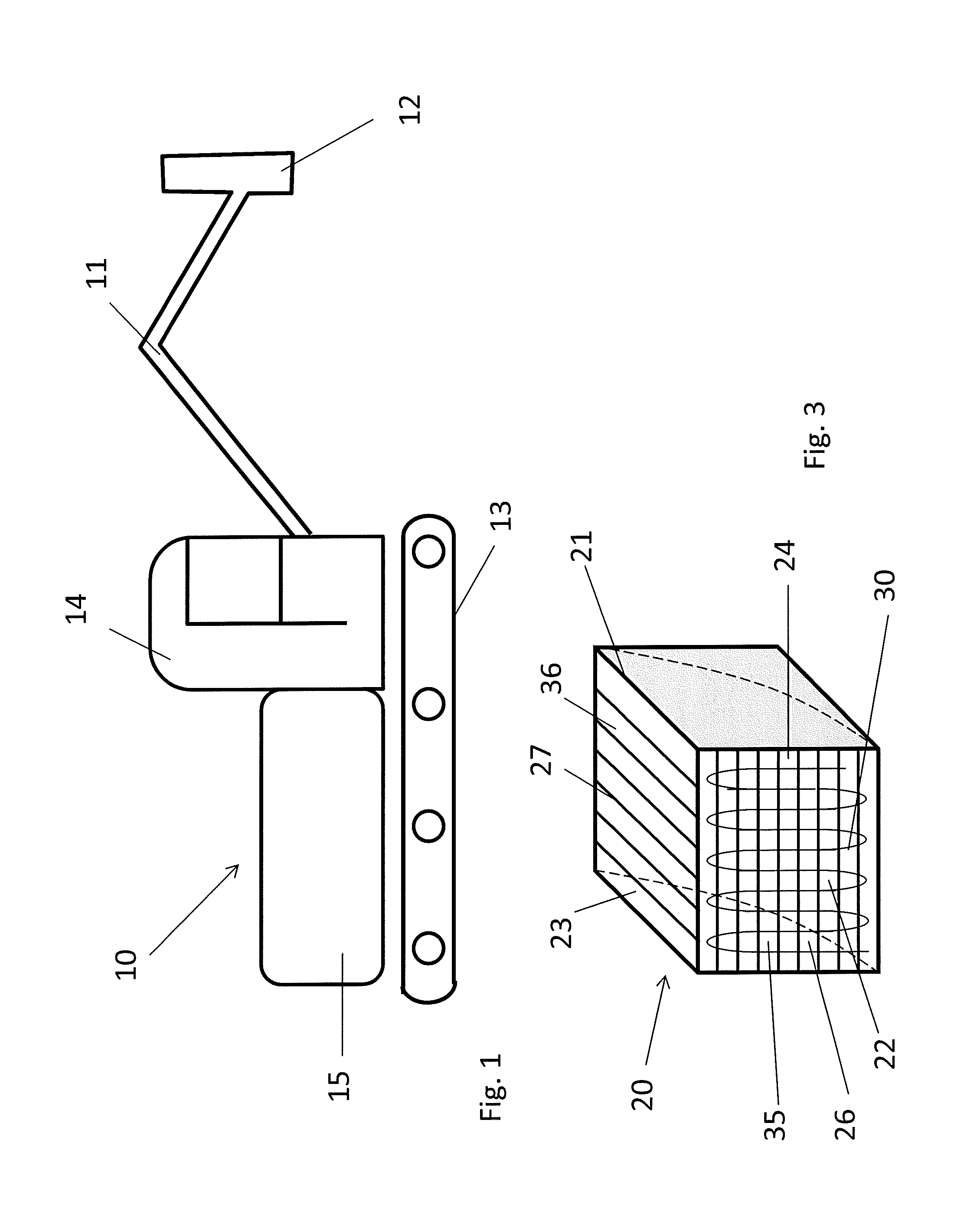

[0042]In FIG. 1, a drill rig 10 for different types of ground and construction works and in which the present invention e.g. may be used is schematically illustrated.

[0043]The drill rig comprises i.e. a longitudinal, movable arm 11, at which end drilling devices 12 are arranged, caterpillar treads 13 to propel the rig, a compartment 14 for the operator and an engine housing 15.

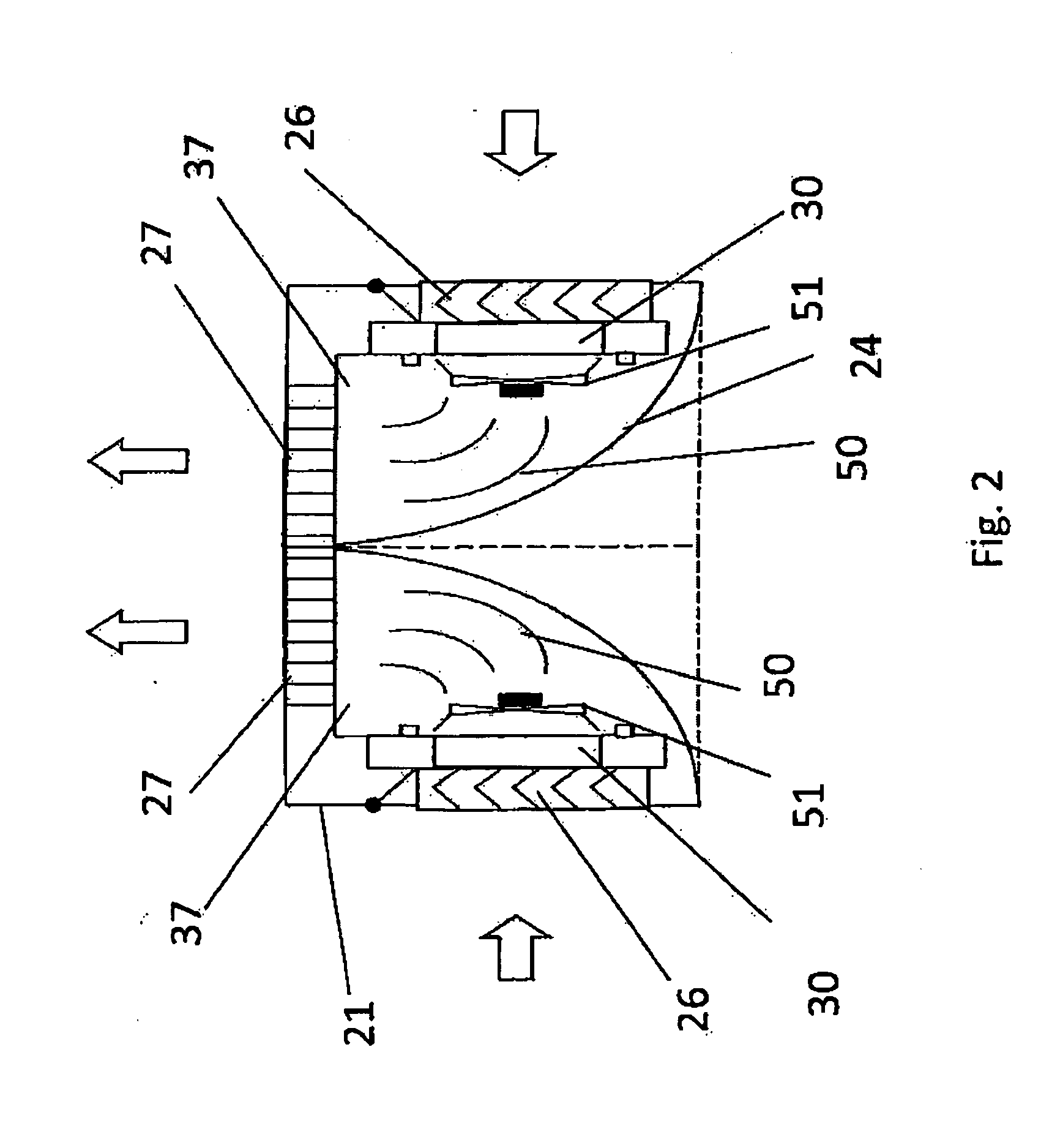

[0044]The engine housing 15 of the drill rig contains a plurality of components and systems that ensures that the rig work properly such as e.g. an engine that supplies the required power to the drill rig. Thus, the engine is used to e.g. propel the rig, move the longitudinal arm and to operate the drilling device. The engine, and a plurality of the different systems and components in the drill rig, produce a considerably amount of heat and thus, require cooling in order to avoid breakdowns and to ensure continuous operation during long periods. The necessity of cooling increases when the load is high and if t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com