Training dummy assembly for doing stand-up drills and ground drills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

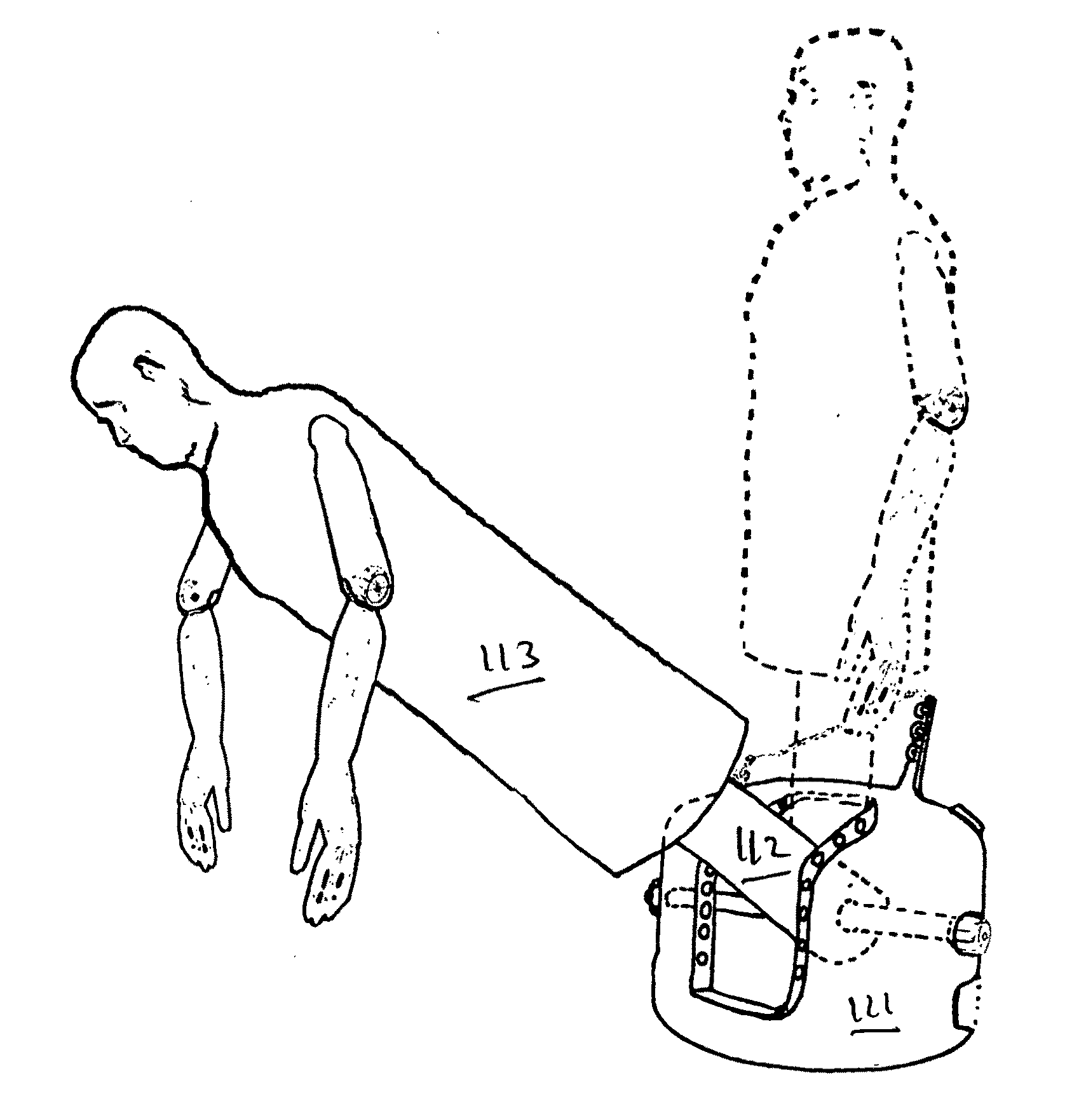

[0079]Referring to FIG. 28 in conjunction with FIG. 29 a training dummy assembly 110 includes a base 111, a column 112, a dummy 113 and a tensioning mechanism 114. The base 111 rests on the ground. The column 112 pivotally coupled the dummy 113 to the base 111. The tensioning mechanism 114 resiliently couples the dummy 113 to the base 111.

[0080]Referring to FIG. 30 the dummy 113 has a shape of a torso 130 with head 131 and is formed out of foam with an outer latex skin. The torso 130 has a pair of shoulders 132 and a pair of arms 133. Each arm 133 has a weighted hand 134 and is pivotally coupled to one of the shoulders 132 of the torso 130. Each arm 133 is free floating and weighted so that when the dummy 113 is either upright or horizontal the weighted hands will cause the arms 133 to continually swing downward for various arm-lock techniques. Each arm 133 includes an upper limb 135 and a lower limb 136, a hinge 137 which forms an elbow and includes a mechanism 138 coupled to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com