Workpiece holding method

a technology for holding workpieces and workpieces, applied in the field of workpiece holding methods, can solve the problems of target workpiece dropping, not always easy to hold such workpieces, etc., and achieve the effects of increasing the number of ways of extracting workpieces, and enhancing the success rate of grasping workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

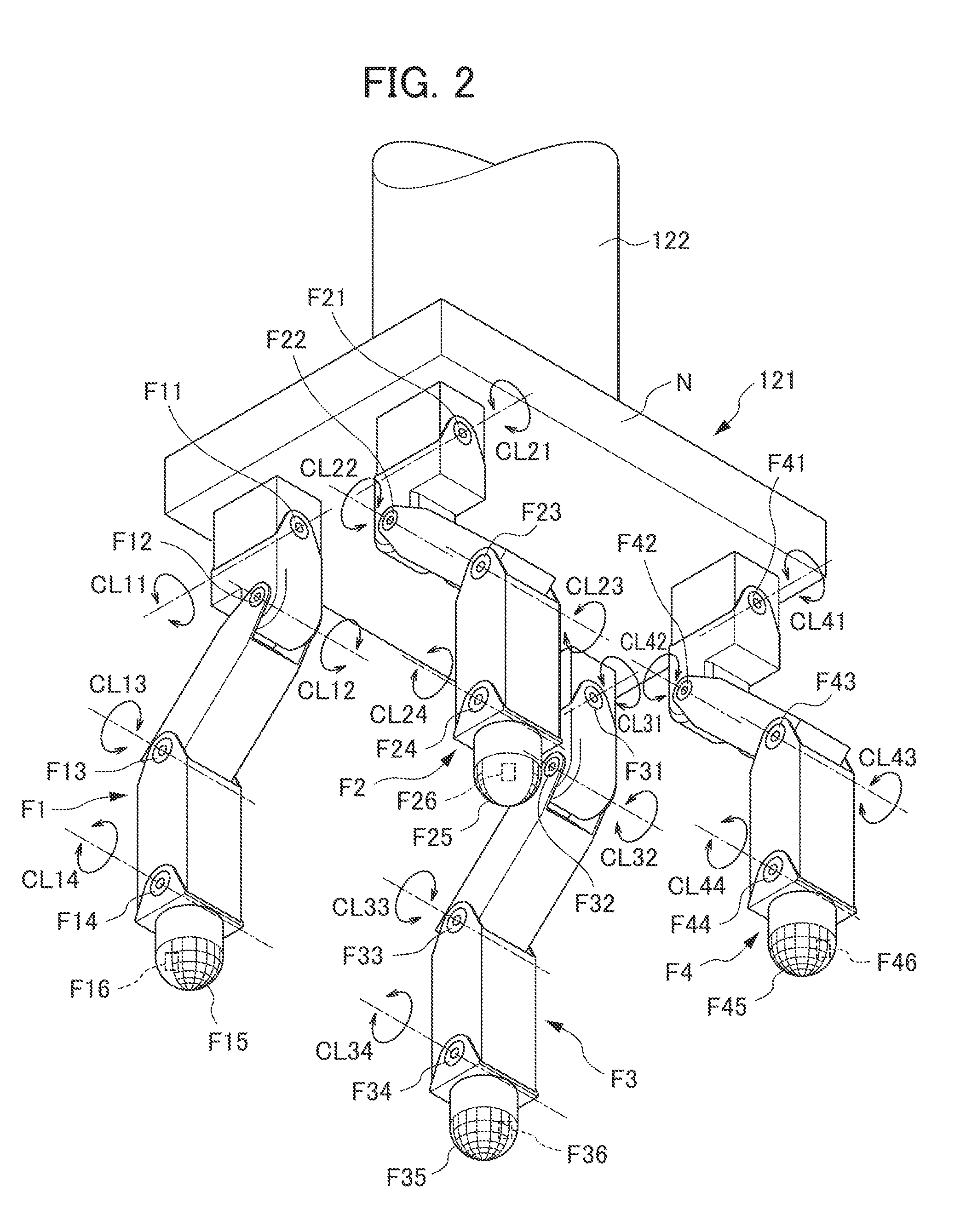

[0029]The following describes an embodiment of the present invention with reference to the drawings.

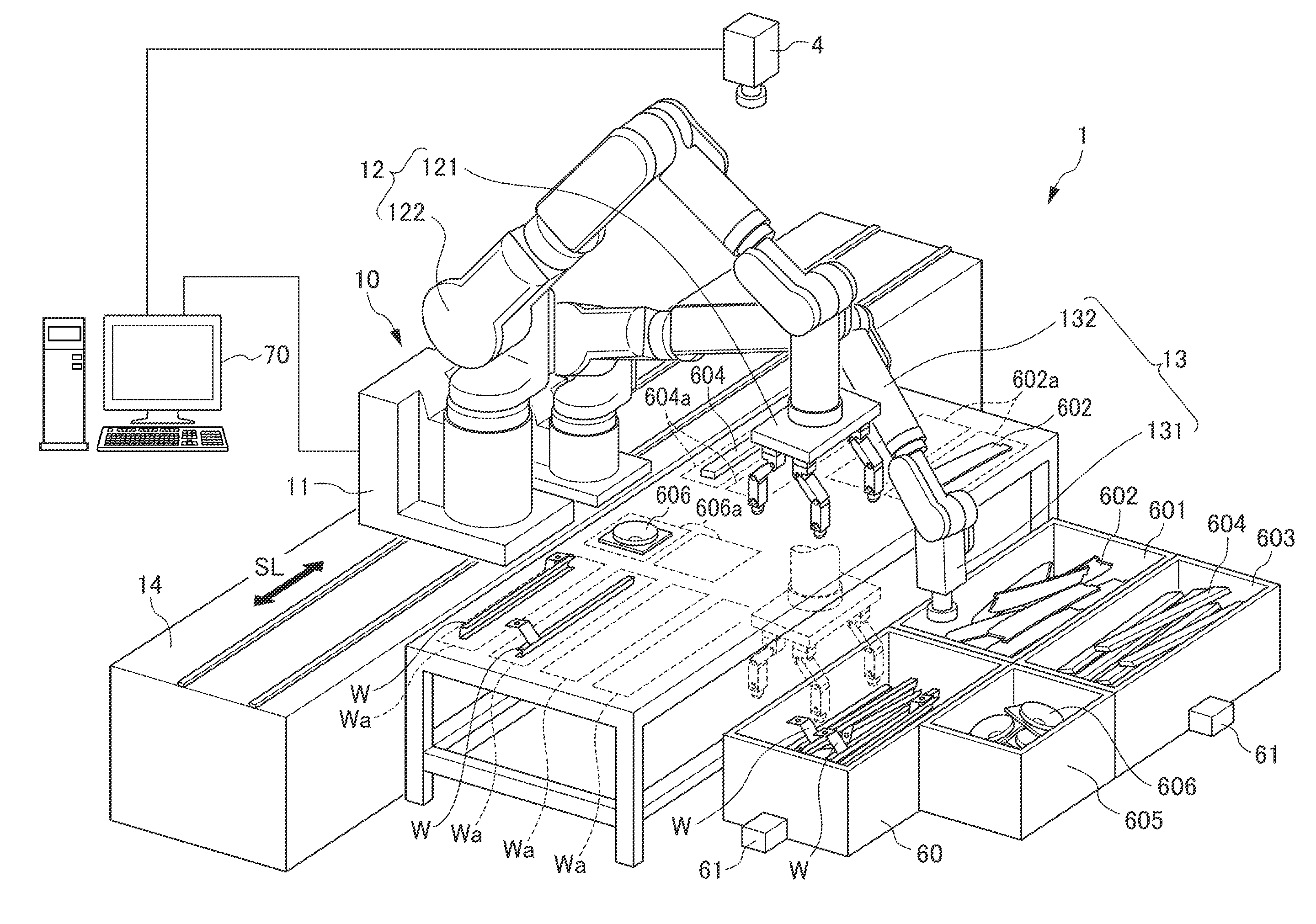

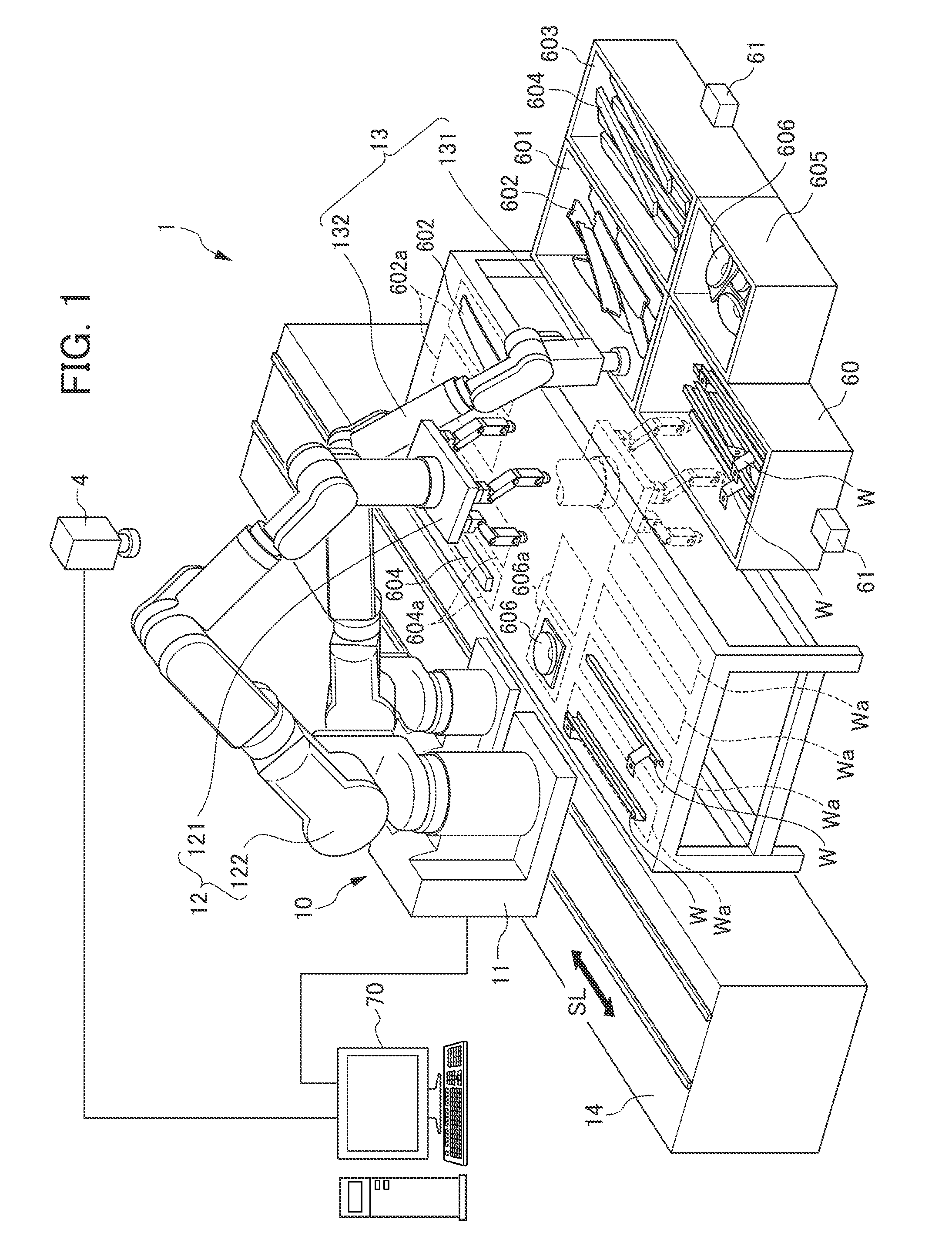

[0030]FIG. 1 is a schematic view showing a configuration of a workpiece layout system 1 as a workpiece layout system used in a workpiece holding method according to one embodiment of the present invention.

[0031]The workpiece layout system 1 is provided on a sub-assembly line that supplies a vehicle assembly line, which assembles a vehicle, with workpieces in a state (laid out state) in which a plurality of predetermined workpieces (assembly parts) are laid out at predetermined positions of a workpiece supply unit. To the workpiece layout system 1, reinforcement W, which is a workpiece, is supplied in a state in which it is contained in a bucket 60. Similarly, a workpiece 602 contained in a bucket 601, a workpiece 604 contained in a bucket 603, and a workpiece 606 contained in a bucket 605 are supplied.

[0032]The reinforcement W is of an elongated shape and is contained in an untidy hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gravity | aaaaa | aaaaa |

| elongated shape | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com