Lubricant circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The following detailed description is merely exemplary in nature and is not intended to application and uses. Furthermore, there is no intention to be bound by any theory presented in the preceding background or summary or the following detailed description.

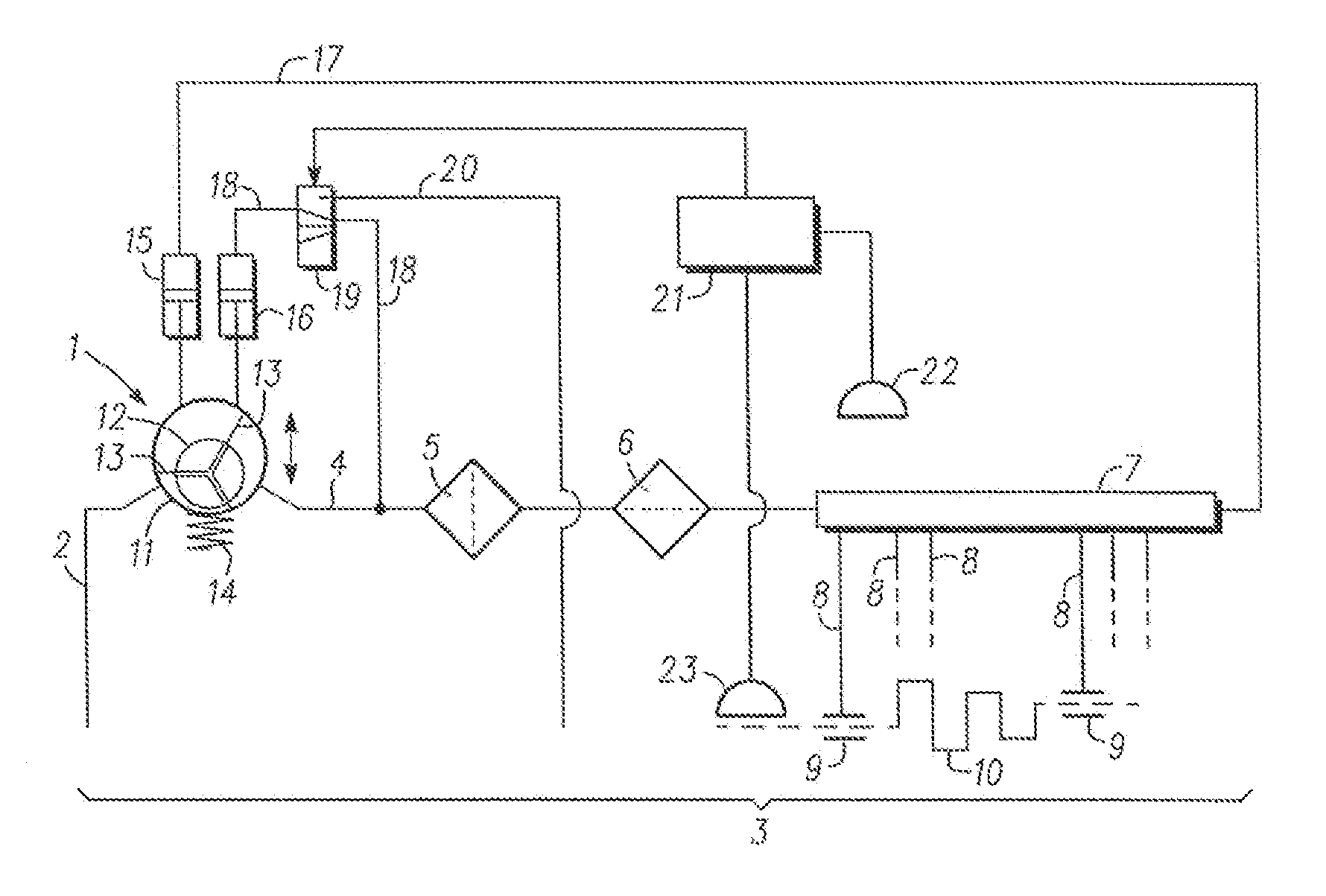

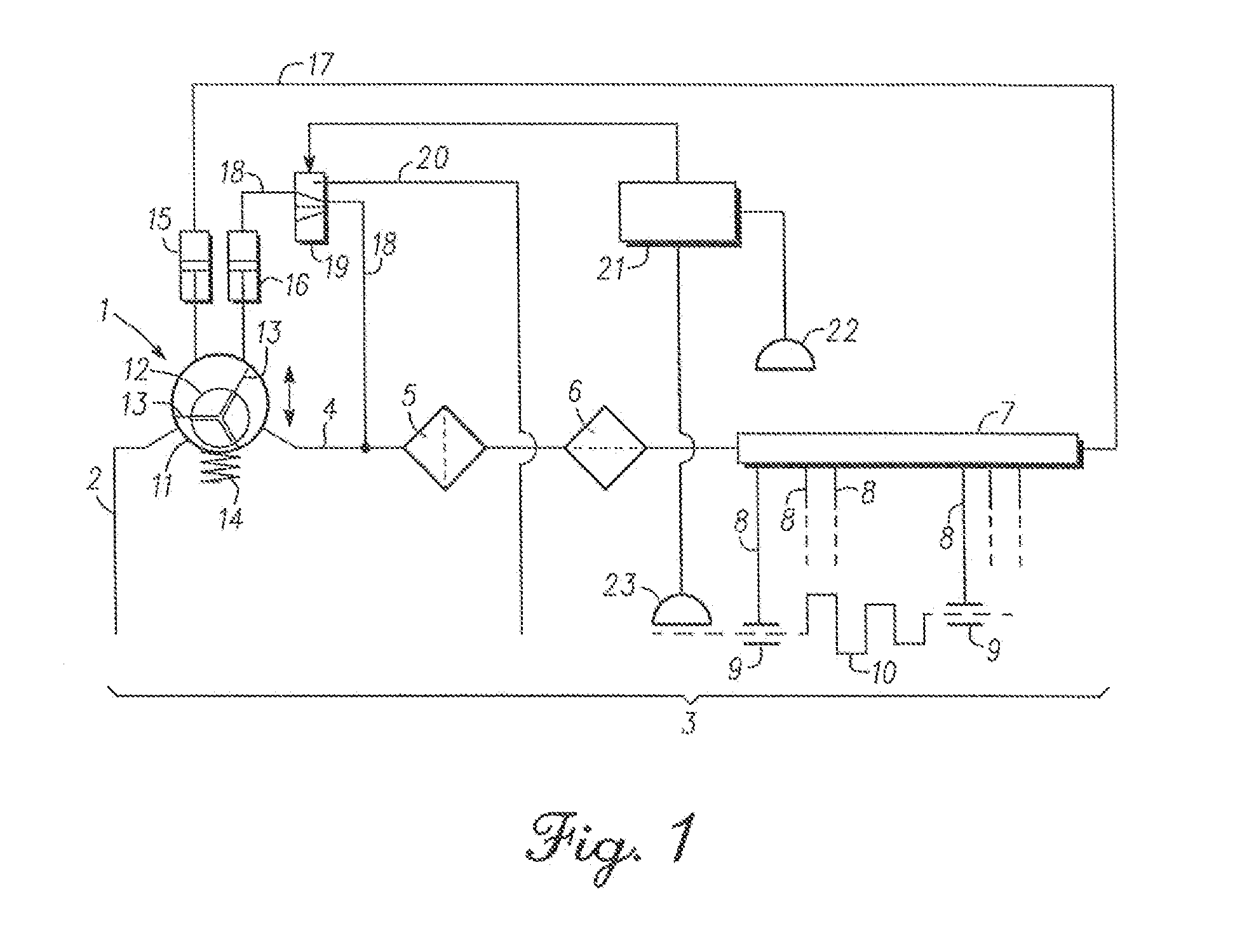

FIG. 1 shows a schematic diagram of an oil circuit in an automobile engine. A vane pump 1 is connected via a suction line 2 to an oil sump 3. A distributor connected to the vane pump 1 on the pressure side comprises a supply line 4, on which an oil filter 5 and an oil cooler 6 are disposed in series, and a gallery 7 from which branch lines 8 branch off to various lubricating points 9 of the engine such as bearings of a crankshaft 10. From the lubricating points 9 the oil runs back into the oil sump 3 unguided.

The vane pump 1 has in a manner known per se a housing 11 having a cylindrical cavity, in which there is provided a rotor 12 having a plurality of vanes 13 held by positioning rings in contact with an inner surface of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com