Method of regulating CSF drainage

a technology of csf drainage and drainage channel, which is applied in the direction of volume/mass flow by thermal effects, wound drainage, intravenous devices, etc., can solve the problems of large risk of passage becoming obstructed, flowmeters are not used, pressure difference sensors generally present problems of stability and drift over time, etc., to achieve effective and reliable drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Mass Flowmeter

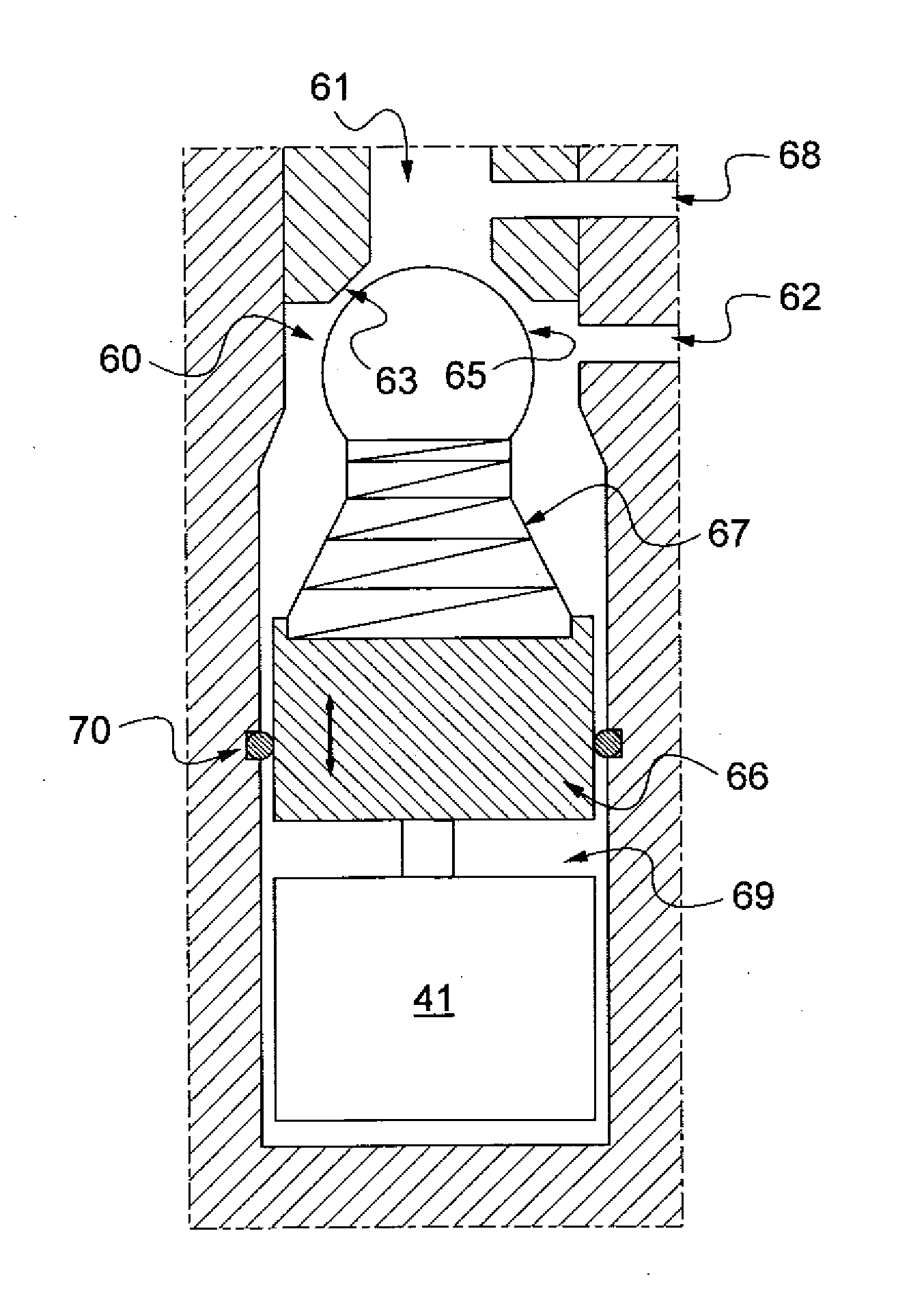

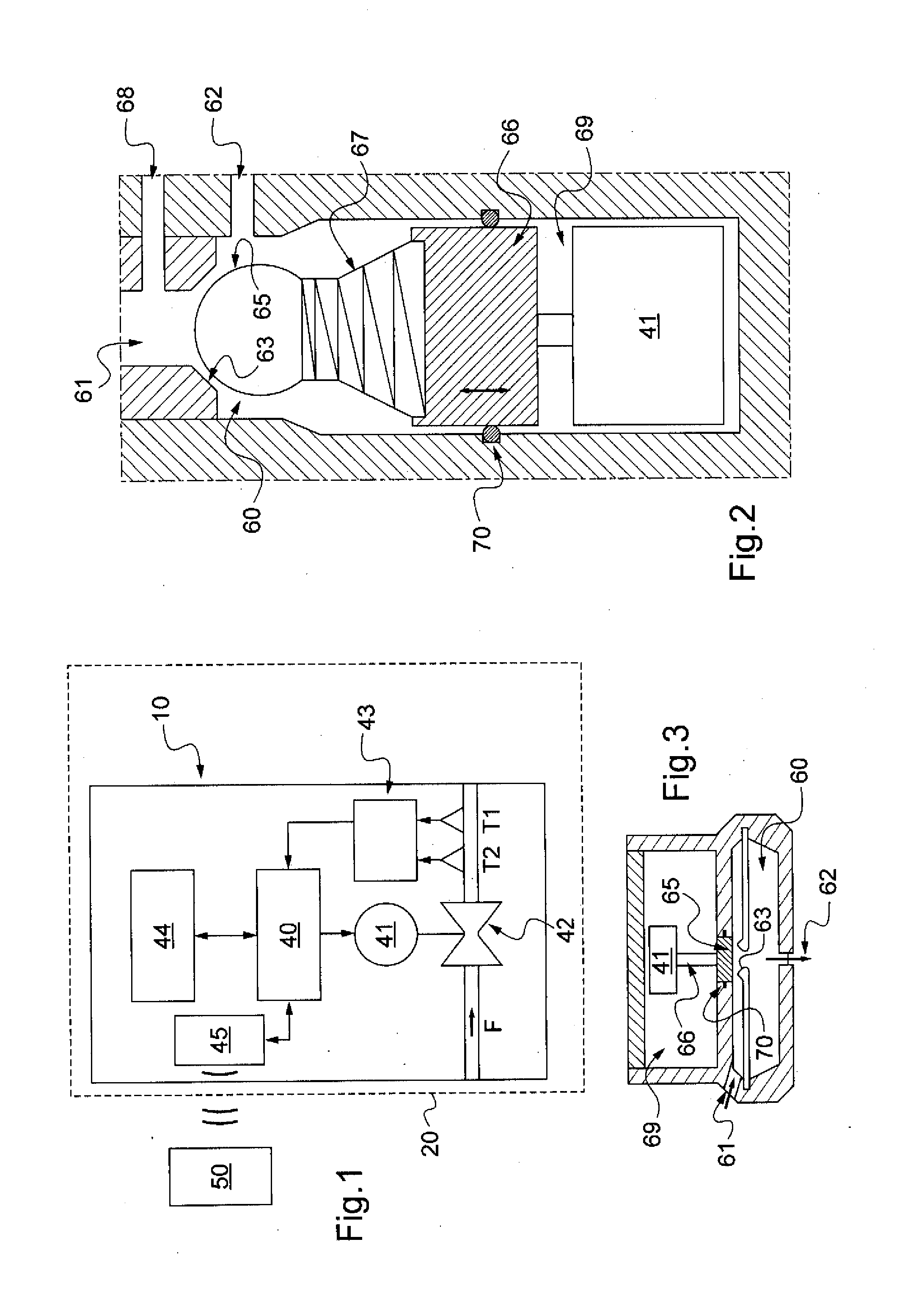

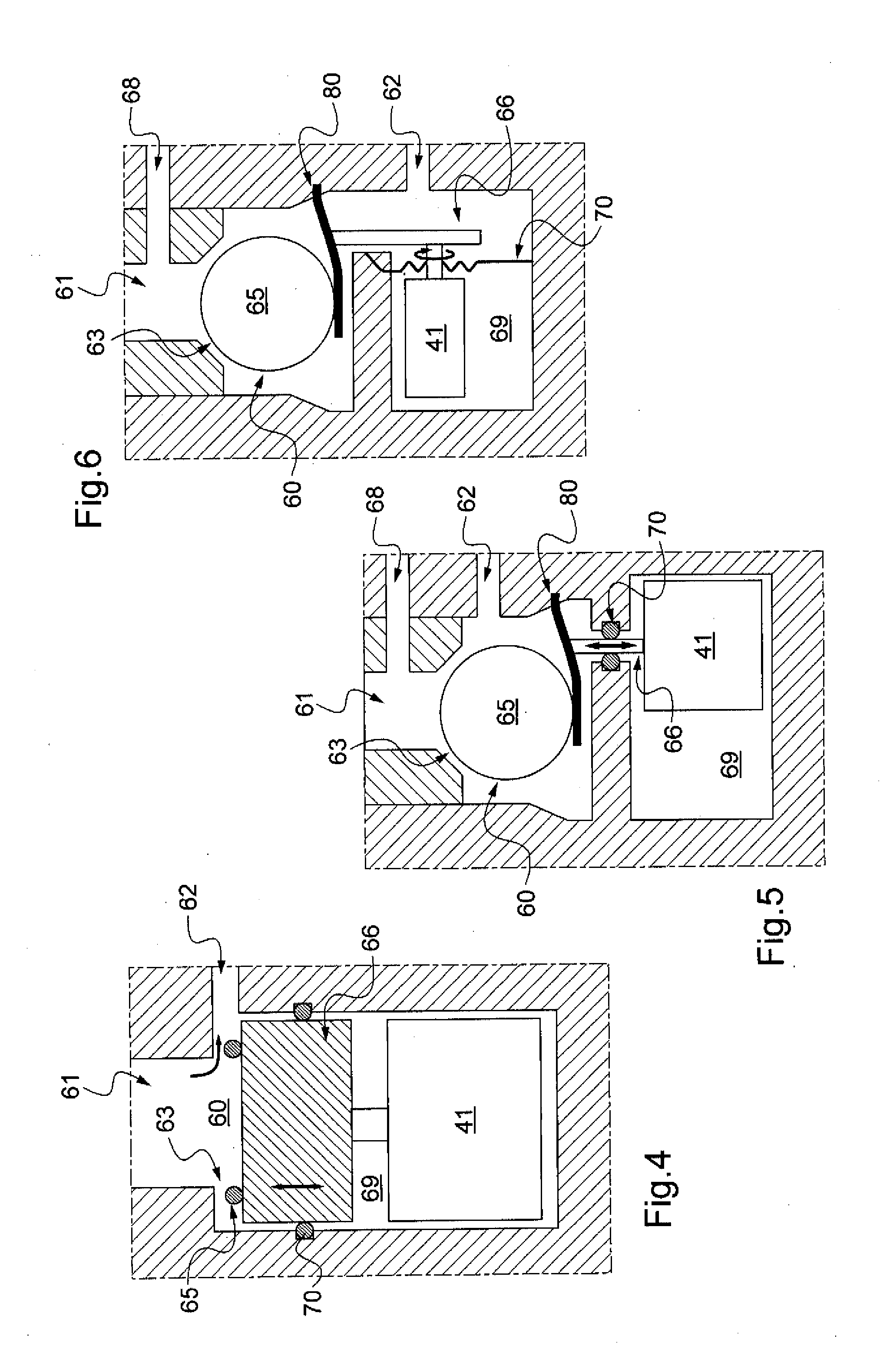

[0009]The term “mass flowmeter” is used to designate a Coriolis effect flowmeter or a thermal flowmeter, i.e. a meter providing measurements of the flow rate of a fluid that depends on the thermal capacity of the fluid. A mass flowmeter therefore needs to be rated as a function of the nature of the fluid for which it is desired to measure the flow rate. Conventionally, the operating principle of a mass flowmeter relies on evaluating heat exchange between the fluid and its environment while the fluid flows between an upstream point and a downstream point. By way of example, the evaluation may result from measuring the power required for maintaining a constant temperature difference between those two points, or conversely from measuring the temperature at the downstream point while the temperature at the upstream point is kept constant. In order to evaluate the flow rate, the mass flowmeter therefore has no need to make use of the pressure difference Pd from upstream to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com