Device for delivering a gas

a gas delivery and gas technology, applied in the direction of positive displacement liquid engines, pumping units, machines/engines, etc., can solve the problems of inability to correspondingly cool or discharge, and failure of membrane pumps, so as to achieve the effect of easy combination with various drive elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

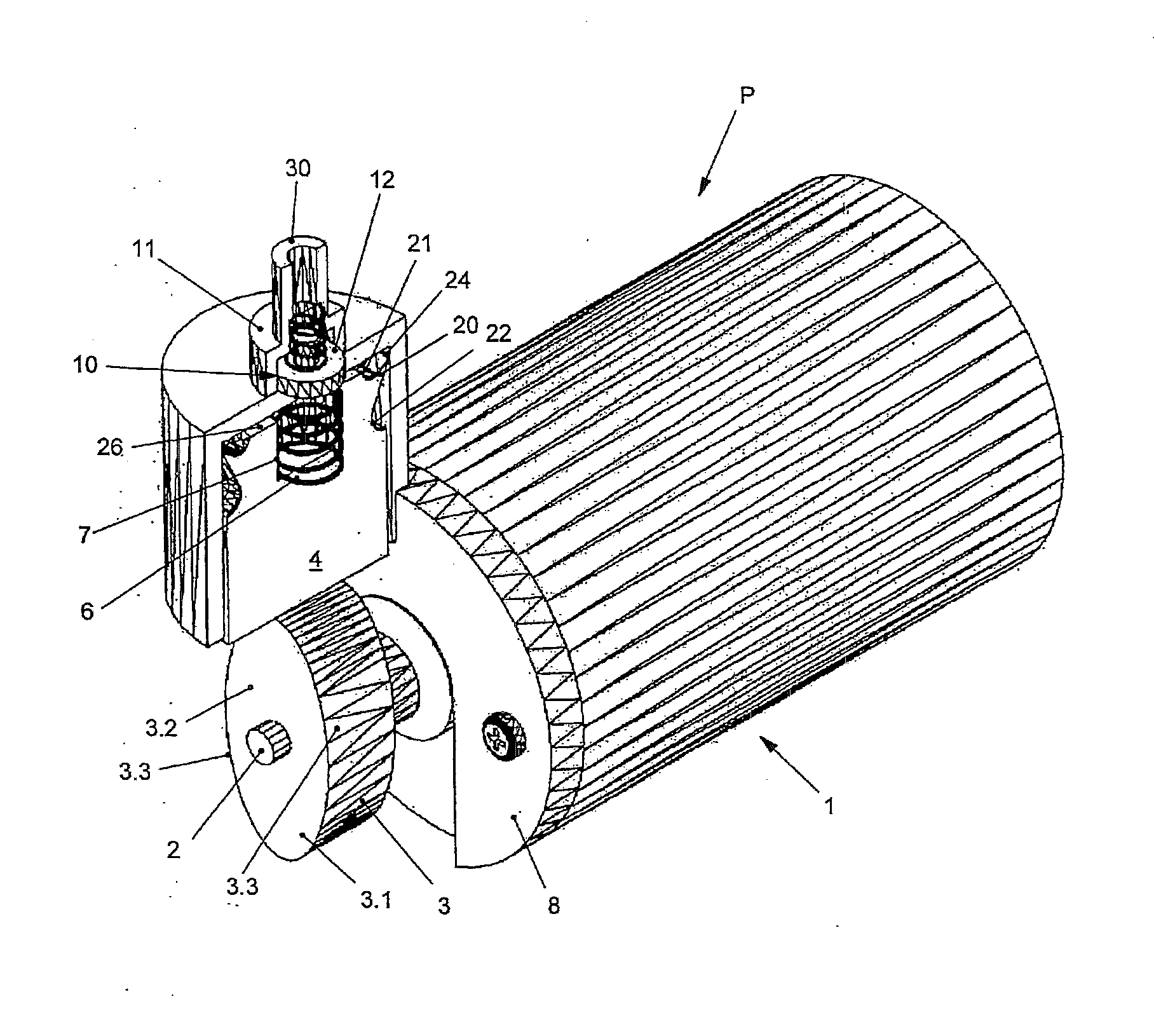

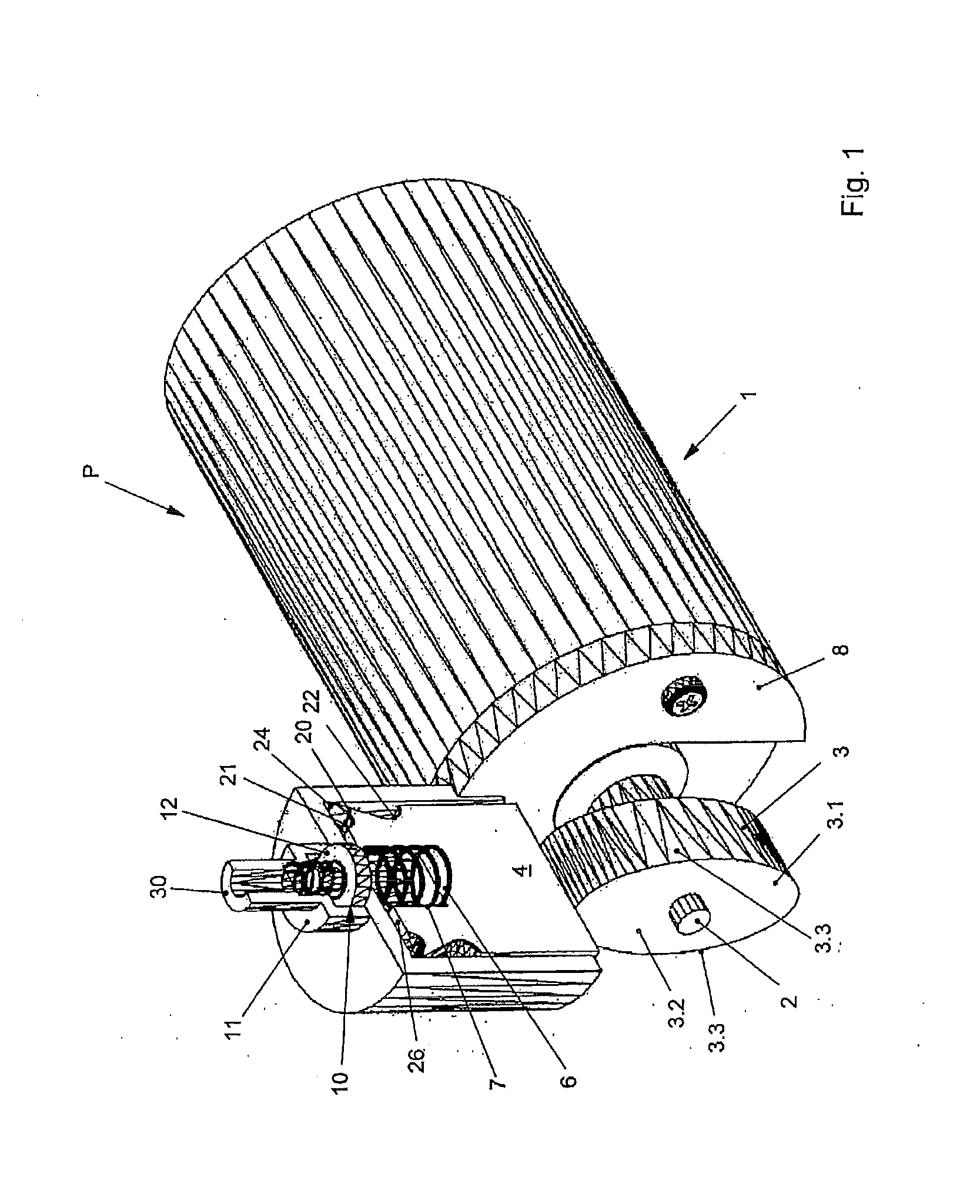

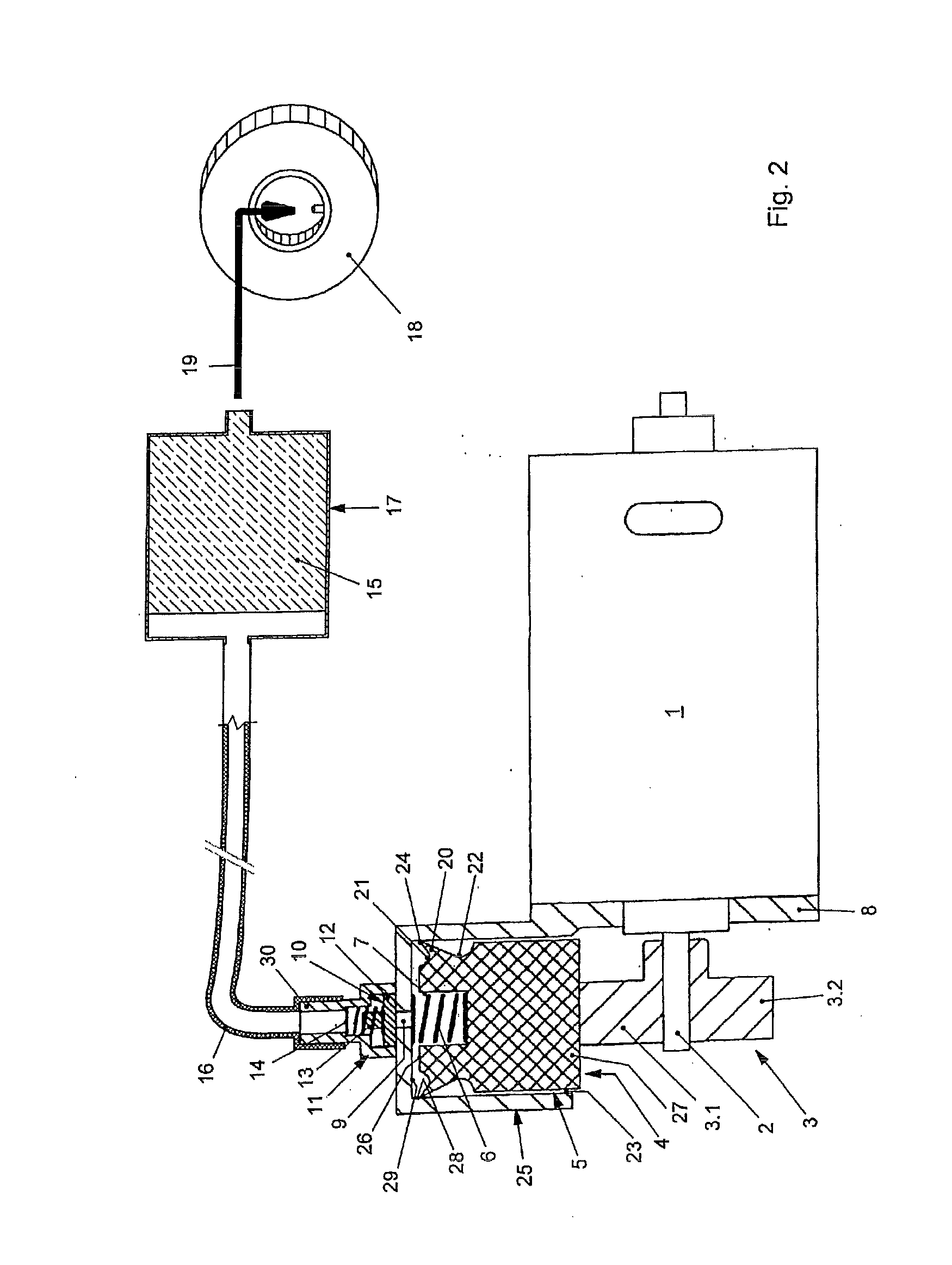

[0034]FIG. 1 shows that the device P for delivering a gas from a pressure chamber 5 has a drive 1 with a drive shaft 2, to which a gear element 3 has been attached in a rotationally fixed fashion. The drive 1 is an electric motor in the preferred embodiment.

[0035]As shown in FIG. 1, the gear element 3 is a double cam 3 with a first projection 3.1 and a second projection 3.2. The double cam 3 has been attached to the drive shaft 2 such that the two projections 3.1 and 3.2 protrude from the drive shaft in a substantially mirror-symmetric fashion. The elliptic shape of the double cam 3 converts the rotational motion of the drive shaft 2 into an oscillatory motion. The oscillatory motion brings about upward and downward motion of a piston 4, which is mounted such that it can move to-and-fro in a pressure chamber 5 (see FIG. 2).

[0036]A force-storage element 6 holds the piston 4 against the gear element 3 under pretension such that the piston is in constant contact with the gear element 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com