[0005]In view of these factors, an object of the invention is to solve at least one of the technical problems found in the prior art so that the temperature of the dispenser casing may be evenly increased with a higher energy efficiency to prevent the dispenser casing from forming condensation and / or to remove any

condensed water from the dispenser casing.

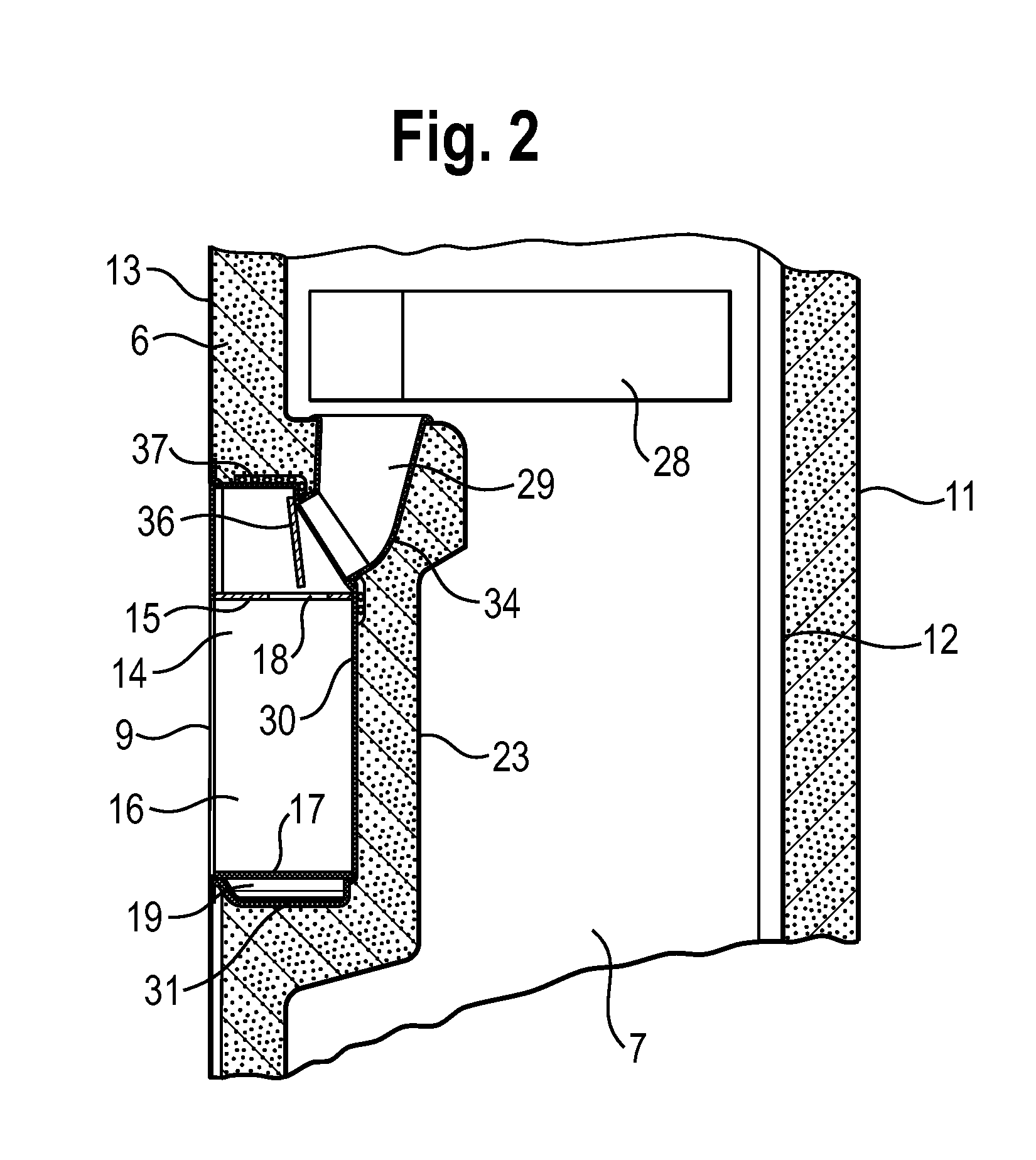

[0007]In this way, the heat generated by the heater can be transmitted to the dispenser casing rapidly and evenly. On one hand, this configuration can prevent the portions of the dispenser casing which are adjacent to the heater from being overheated and the portions of the dispenser casing which are distant from the heater from being under heated and thus generating condensate, so that it is expected that condensation on the dispenser casing can be avoided with a reasonable

energy consumption. On the other hand, by means of the heat transmitting function of the

heat conducting element, the reaching area of the heat generated by the heater can be enlarged by the heat conducting element. That is to say, the heat generated by the heater may form a heat source for the heat conducting element and will be transmitted quickly by the heat conducting element, so that the deploying area of the heater can be advantageously reduced. For example, only the portions of the dispenser casing which are likely to occur condensation may be provided with a heater while other portions of the dispenser casing which are not likely to occur condensation may be only covered and supplied with heat by the heat conducting element.

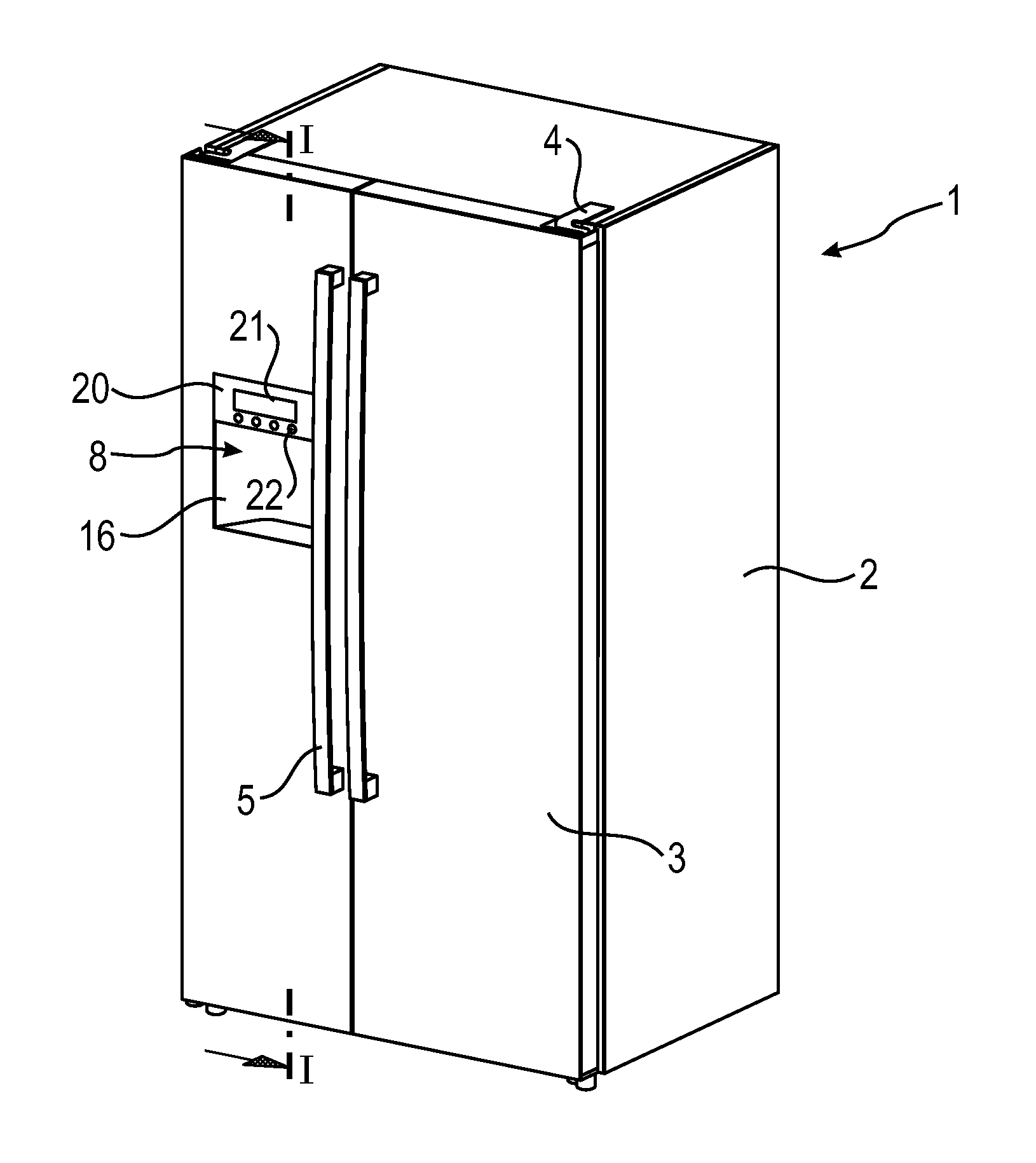

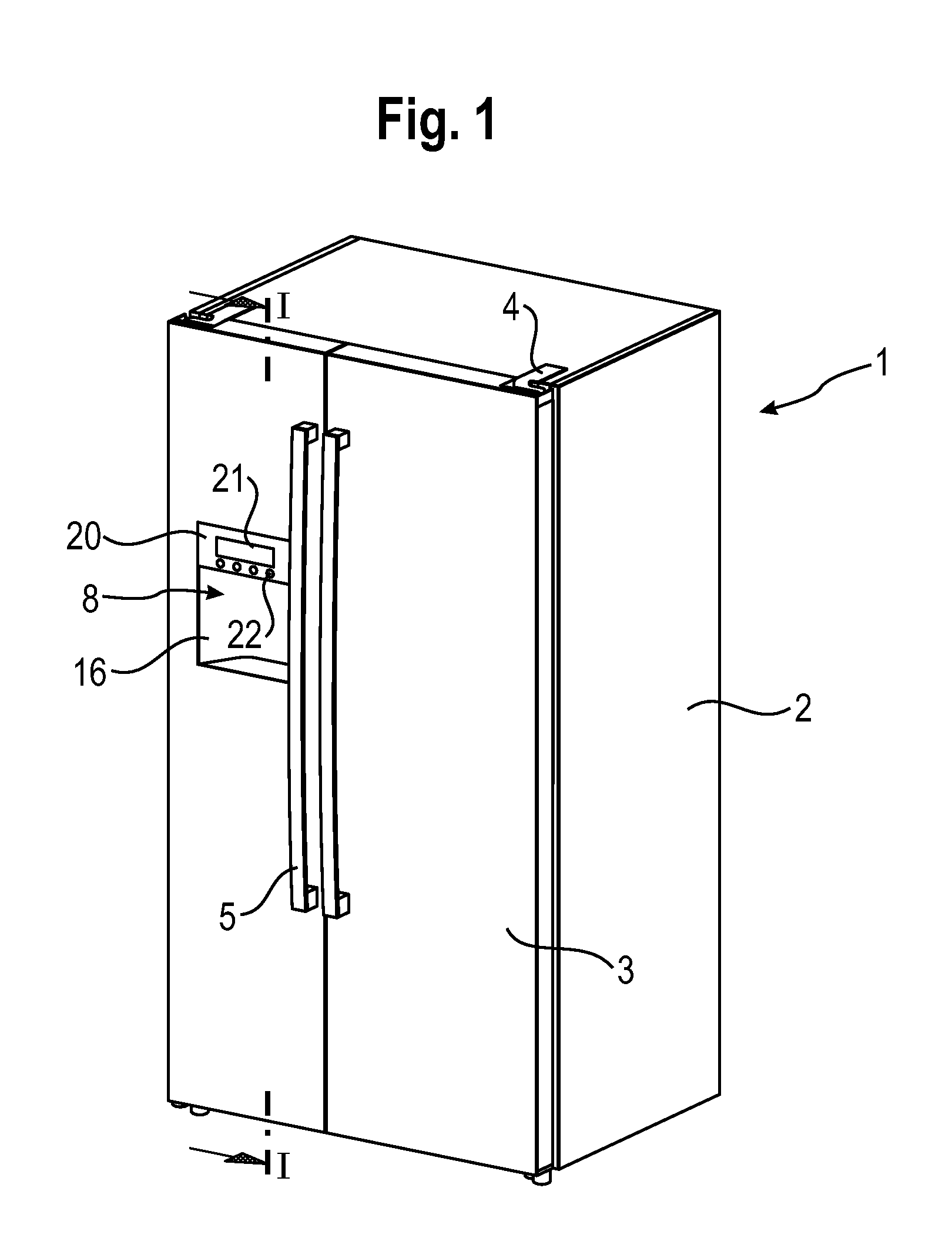

[0010]According to a preferred embodiment of the invention, the dispenser casing defines a dispensing cavity for receiving at least a part of an outside container, the dispensing cavity comprises a dispensing

cavity wall extending in a longitudinal direction, and the heat conducting element covers at least a major portion of the dispensing

cavity wall. Thus, the dispensing

cavity wall may be evenly heated to reduce the possibility of occurring condensation. In addition, the dispensing cavity wall may be touched by a user. For this end, the heat conducting element is provided for preventing the dispensing cavity wall from being overheated, and thus any

potential harm to the user by the overheated dispensing cavity wall can be avoided.

[0015]According to a preferred embodiment of the invention, the heater is arranged adjacent to the ice transfer passage. In this way, the portions of the dispenser casing which are located near the ice transfer passage will obtain more heat, so that the condensation possibility can be reduced. In addition, in the condition that the ice transfer passage is blocked by a closure element which closes a through hole, the condition that the closure element is frozen and thus cannot be opened can be advantageously avoided by means of the first heater provided adjacent to the ice transfer passage.

[0016]Although it is possible to arrange the heater adjacent to the dispenser casing but not directly contact with the dispenser casing, it is preferably that the heater is connected to the dispenser casing according to a preferred embodiment of the invention, so that the heat generated by the heater may be transmitted quickly to the dispenser casing, and thus the influence of the heat generated by the heater to the storage space is reduced.

[0017]According to a preferred embodiment of the invention, the heater comprises a first heater and a second heater which are controlled independently from each other. According to a preferred embodiment of the invention, the dispenser casing comprises a first area and a second area located near the first area, the first area and the second area are arranged adjacent to the heat insulating layer, and the first and second heater are disposed in the first area and the second area respectively. Thus, condensation can be prevented more effectively. For example, different heaters may be properly disposed according to the condensation characteristics of different areas of the dispenser casing, and it may prevent the occurring of condensation or removing the generated condensate more efficiently by individually control these heaters.

Login to View More

Login to View More  Login to View More

Login to View More