Artificial hair fiber, use thereof and process for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

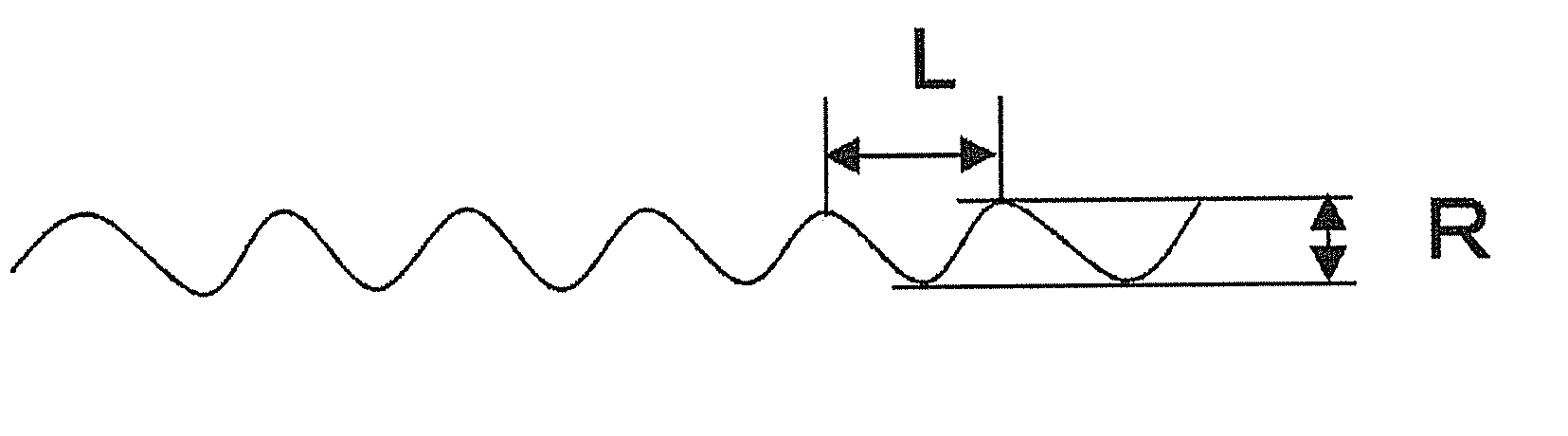

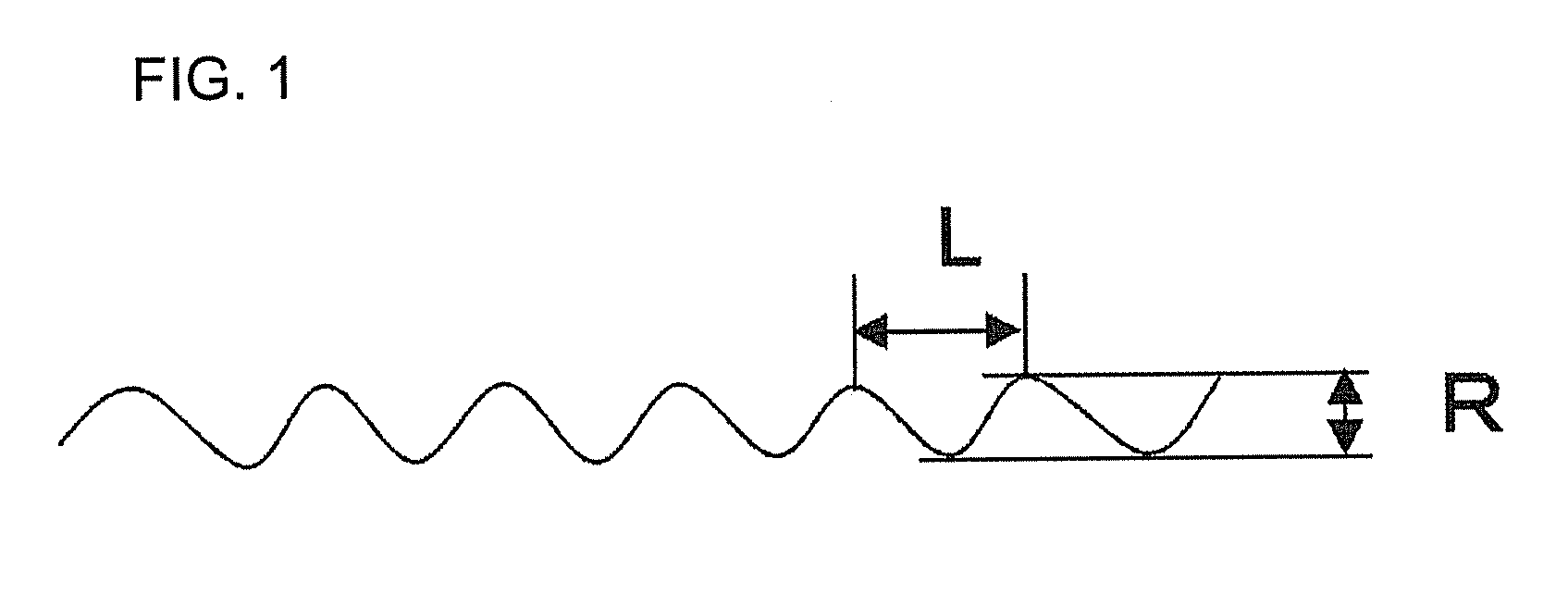

Artificial Hair Fiber

[0055]Qualities of an artificial hair fiber according to the present invention tend to be enhanced when the flexural rigidity measured by the KES method of the artificial hair fiber is moderately large because the artificial hair fiber with such a large flexural rigidity can maintain a gear wave shape and the crimps thereof is not easily undone. In contrast, when the rigidity is moderately small, the feel of the artificial hair fiber tends to be enhanced. Because of the above, the flexural rigidity, as measured by the KES method, of the artificial hair fiber according to this embodiment is preferably between 0.001 and 0.01 gf·cm2, and more preferably between 0.002 and 0.008 g·cm2.

[0056]It has been demonstrated in Examples below that the above artificial hair fiber is excellent in curl uniformity and feel. Because of this the above artificial hair fibers are particularly suitable for an application which is utilized to make the artificial hair fibers curled or fo...

embodiment 2

Process for Producing an Artificial Hair Fiber by Using a Polyamide Resin as a Raw Material

[0081]Another embodiment of the present invention provides a process for producing an artificial hair fiber formed by using a polyamide resin as a raw material, the process comprising: a melt-spinning step of melt-spinning a polyamide resin at a spinneret temperature of 260 to 300° C.; and a stretching step of stretching melt-spun fibers under an atmosphere having a stretching temperature of 90 to 120° C. at a stretching ratio of 200 to 400%.

[0082]This production process can yield an artificial hair fiber having a flexural rigidity of from 0.001 to 0.01 g·cm2 as measured by the KES method.

[0083]In addition, a process for producing an artificial hair fiber formed by using the above polyamide resin as a raw material may include a thermal relaxing step of subjecting the fibers stretched at the above stretching step to thermal relaxing treatment under an atmosphere of air at a temperature of 140 t...

embodiment 3

Process for Producing an Artificial Hair Fiber by Using a Vinyl Chloride Resin as a Raw Material

[0085]Another embodiment of the present invention provides a process for producing an artificial hair fiber formed by using a vinyl chloride resin as a raw material, the process comprising:[0086]a mixing step of mixing a vinyl chloride resin and an additive;[0087]a melt-spinning step of melt-spinning a composition containing the mixed vinyl chloride resin at a spinneret temperature of 160 to 190° C.;[0088]a stretching step of stretching melt-spun fibers under an atmosphere at a stretching temperature of 90 to 120° C., at a stretching ratio of 200 to 400%; and[0089]a thermal relaxing step of subjecting the stretched fibers to thermal relaxing treatment under an atmosphere of air at a temperature of 110 to 140° C. until the entire length of the fibers becomes 60 to 95% of the length before the treatment.

[0090]This production process can yield an artificial hair fiber having a flexural rigid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com