In2S3/MIL-53 (Fe) efficient photocatalytic composite material as well as preparation method and application thereof

A composite material and photocatalytic technology, which is applied in the field of wastewater treatment, can solve the problems of low semiconductor photocatalytic activity and narrow spectral response range, and achieve the effects of enhancing visible light absorption intensity, improving photocatalytic activity, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example gives an In 2 S 3 / MIL-53(Fe) efficient photocatalytic composite material, In 2 S 3 The mass ratio to MIL-53 (Fe) is 10:1 respectively.

[0045] In 2 S 3 In with a mass ratio of 10:1 to MIL-53(Fe) 2 S 3 / MIL-53(Fe) high-efficiency photocatalytic composite material is denoted as IM1;

[0046] In this example 2 S 3 The preparation method of / MIL-53 (Fe) high-efficiency photocatalytic composite material is characterized in that, the method is specifically carried out according to the following steps:

[0047] Step 1, InNO 3 4.5H 2 O is mixed with MIL-53(Fe) and added to water;

[0048] Step 2, dissolving L-cysteine in water equal to step 1;

[0049] Step 3, under stirring conditions, add the solution in step 2 dropwise to the mixed solution in the above step 1, after stirring at room temperature, transfer it to a polytetrafluoroethylene-lined autoclave, and seal the reaction;

[0050] In step 4, after the reaction in step 3 is completed, the rea...

Embodiment 2

[0058] This example gives an In 2 S 3 / MIL-53(Fe) efficient photocatalytic composite material, In 2 S 3 The mass ratio to MIL-53 (Fe) is 20:1 respectively.

[0059] In 2 S 3 In with a mass ratio of 20:1 to MIL-53(Fe) 2 S 3 / MIL-53 (Fe) high-efficiency photocatalytic composite material is denoted as IM2.

[0060] In this example 2 S 3 The preparation method of / MIL-53 (Fe) high-efficiency photocatalytic composite material is basically the same as Example 1, the difference is only in:

[0061] In step one, InNO 3 4.5H 2 The concentration of O is 0.92mM respectively;

[0062] In the second step, the concentration of L-cysteine was 2.76mM respectively.

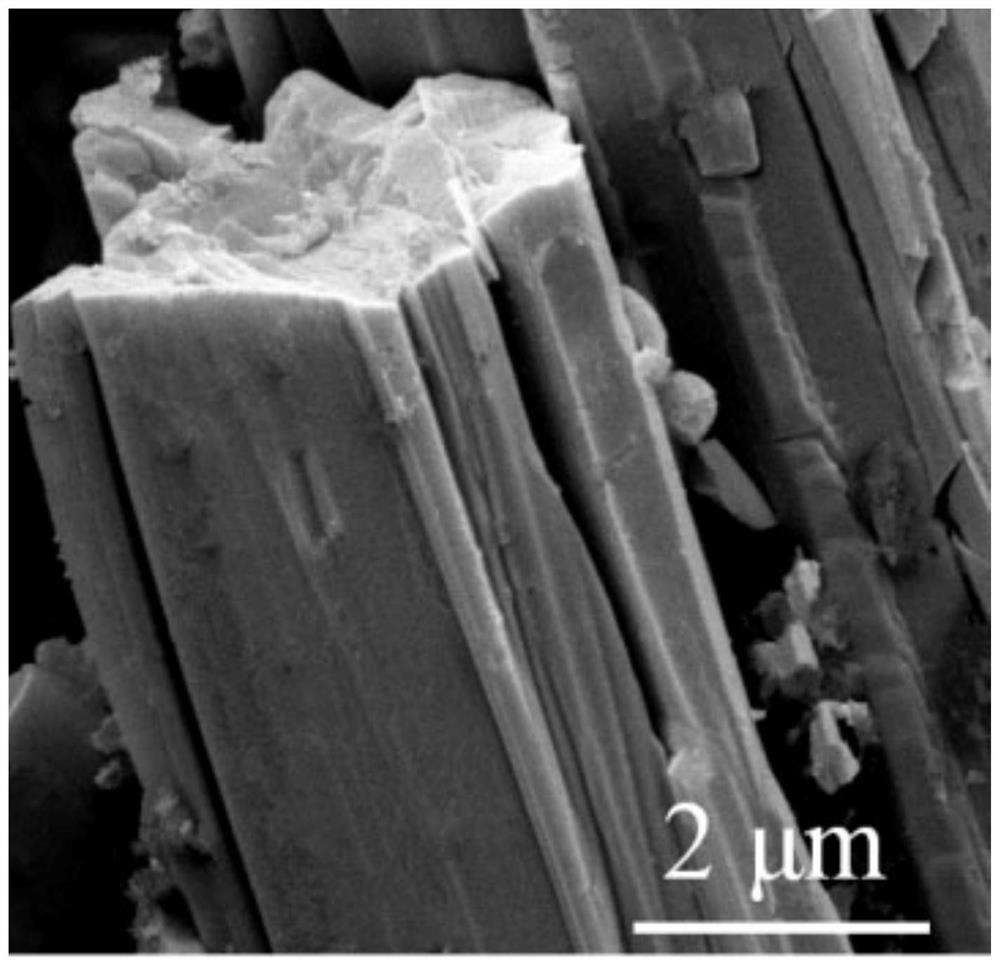

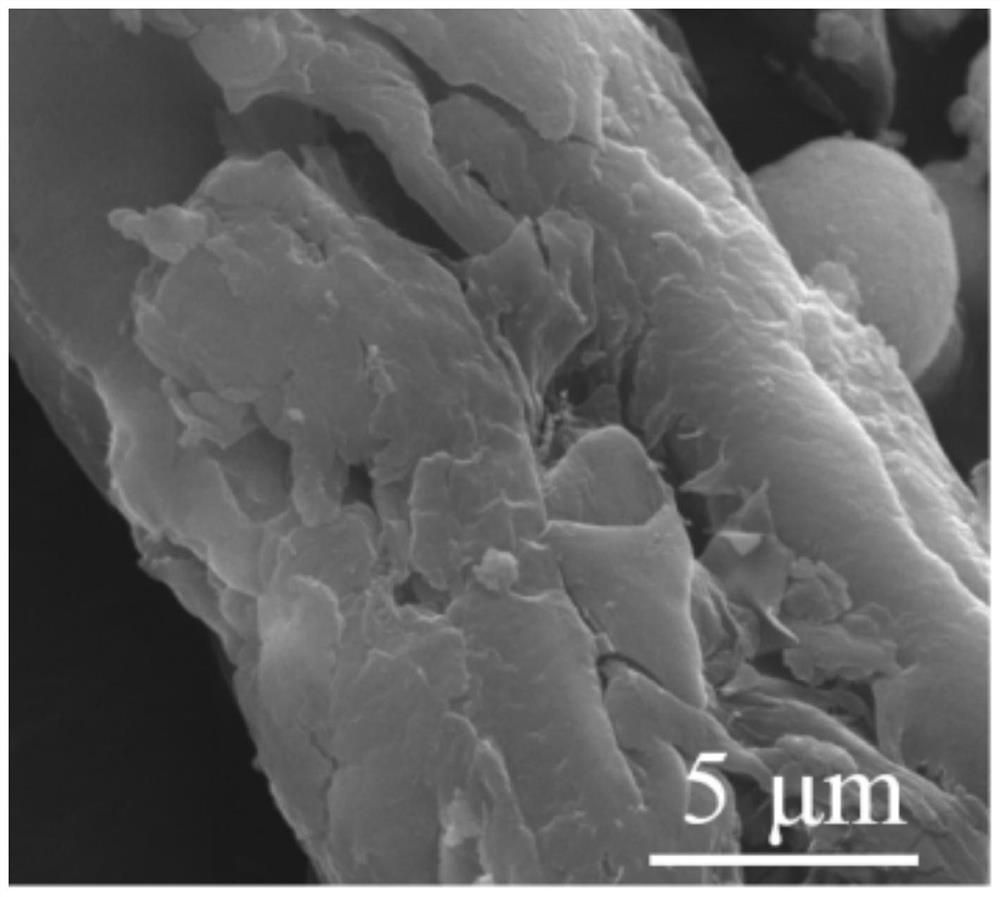

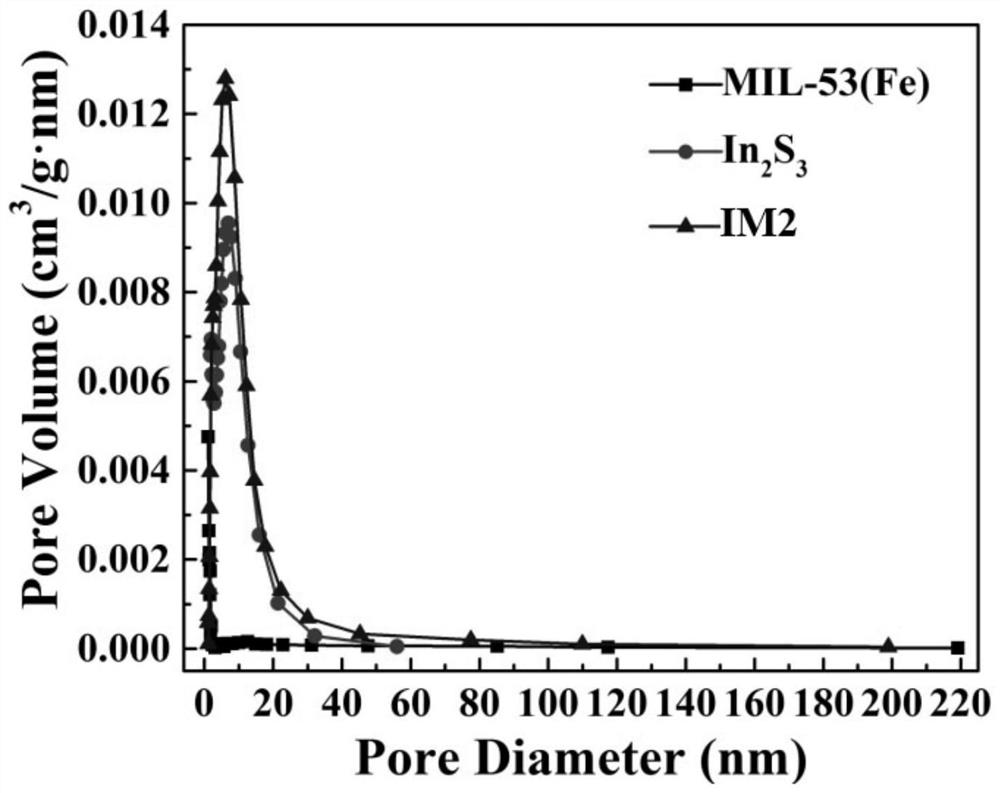

[0063] The In that embodiment 2 makes 2 S 3 The SEM images of the high-efficiency photocatalytic composite IM2 / MIL-53(Fe) and the monomer MIL-53(Fe) under high magnification are shown in Fig. 1. It can be seen from Figure 1(a) that MIL-53 (Fe) presents a rod-like morphology with a diameter of about 5-6 μm and a r...

Embodiment 3

[0066] This example gives an In 2 S 3 / MIL-53(Fe) efficient photocatalytic composite material, In 2 S 3 The mass ratio to MIL-53 (Fe) is 30:1 respectively.

[0067] In 2 S 3 In with a mass ratio of 30:1 to MIL-53(Fe) 2 S 3 / MIL-53 (Fe) high-efficiency photocatalytic composite material is denoted as IM3.

[0068] In this example 2 S 3 The preparation method of / MIL-53 (Fe) high-efficiency photocatalytic composite material is basically the same as Example 1, the difference is only in:

[0069] In step one, InNO 3 4.5H 2 The concentration of O was 1.38mM, respectively;

[0070] In the second step, the concentration of L-cysteine was 4.14mM respectively.

[0071] The In that embodiment 1 to embodiment 3 makes 2 S 3 / MIL-53(Fe) high-efficiency photocatalytic composite material IM1~3 and monomer MIL-53(Fe), monomer In 2 S 3 The UV-visDRS spectrum and PL spectrum are as follows image 3 , Figure 4 shown.

[0072] image 3 It is monomer MIL-53(Fe), monomer In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com