Stove structure

a technology of stove and structure, which is applied in the direction of stoves or ranges, lighting and heating apparatus, heating types, etc., can solve the problems of high manufacture and maintenance costs, inability to effectively lower the temperature, and lack of heat insulation effect, so as to reduce the contact area of heat conduction, reduce the contact area, and reduce the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

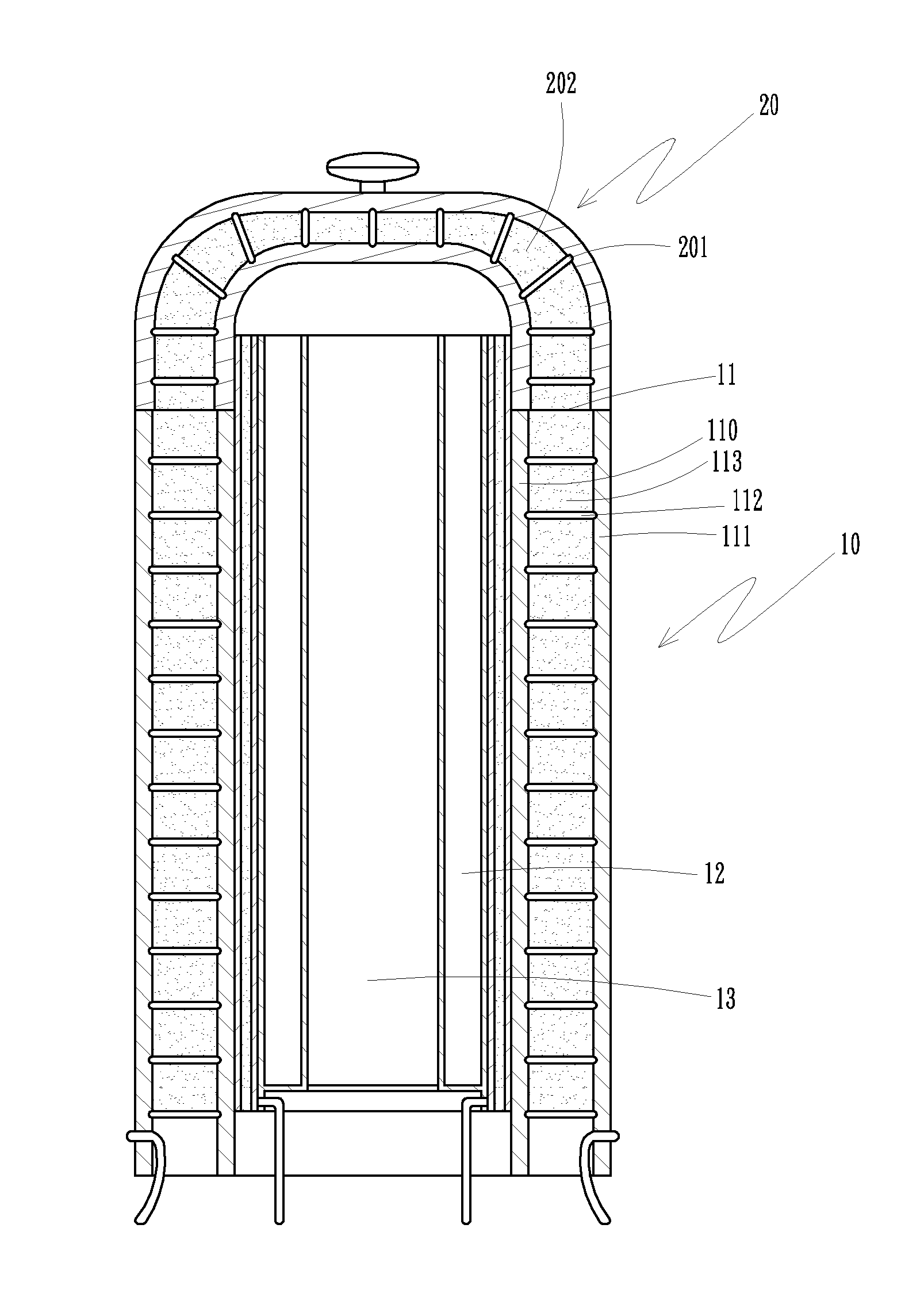

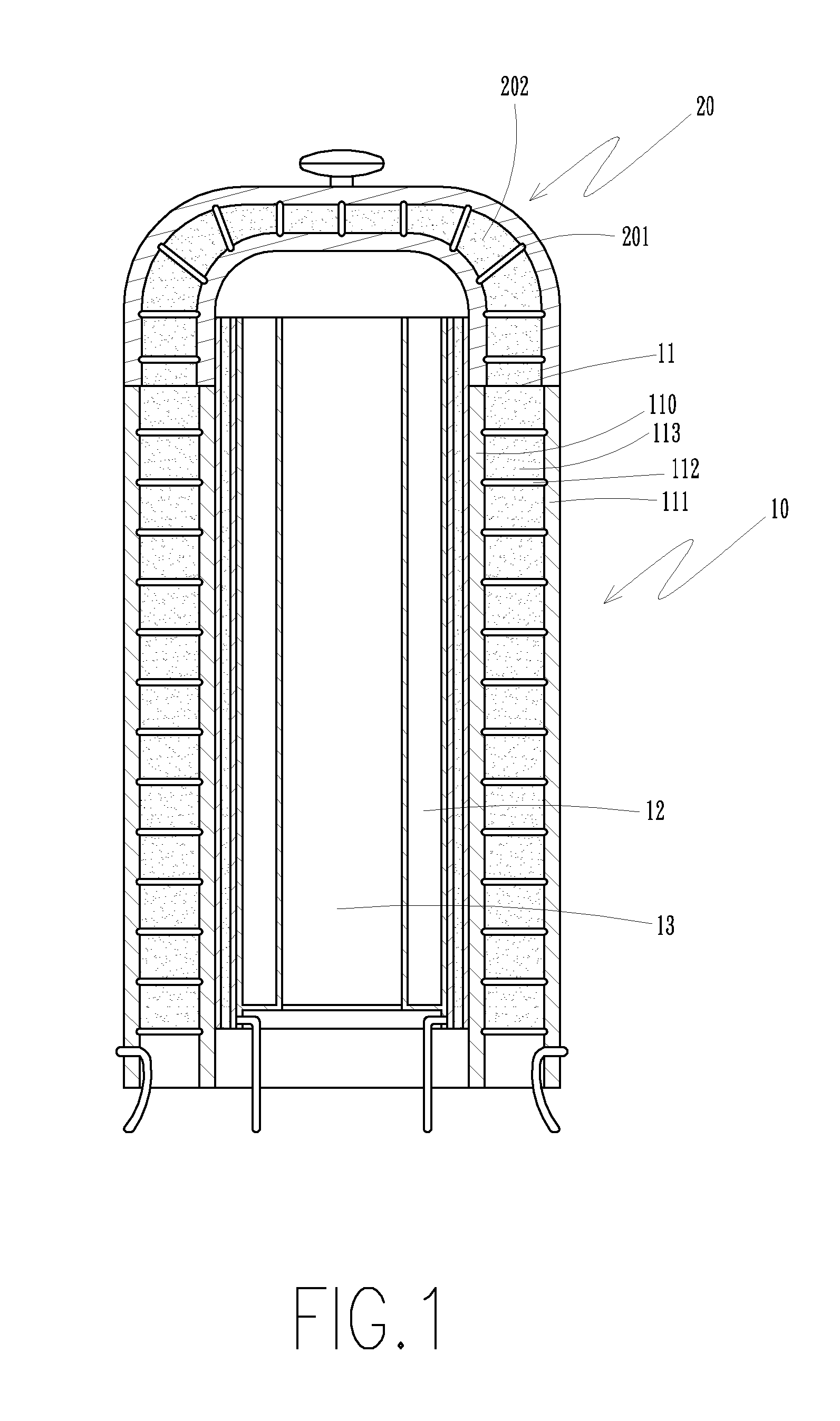

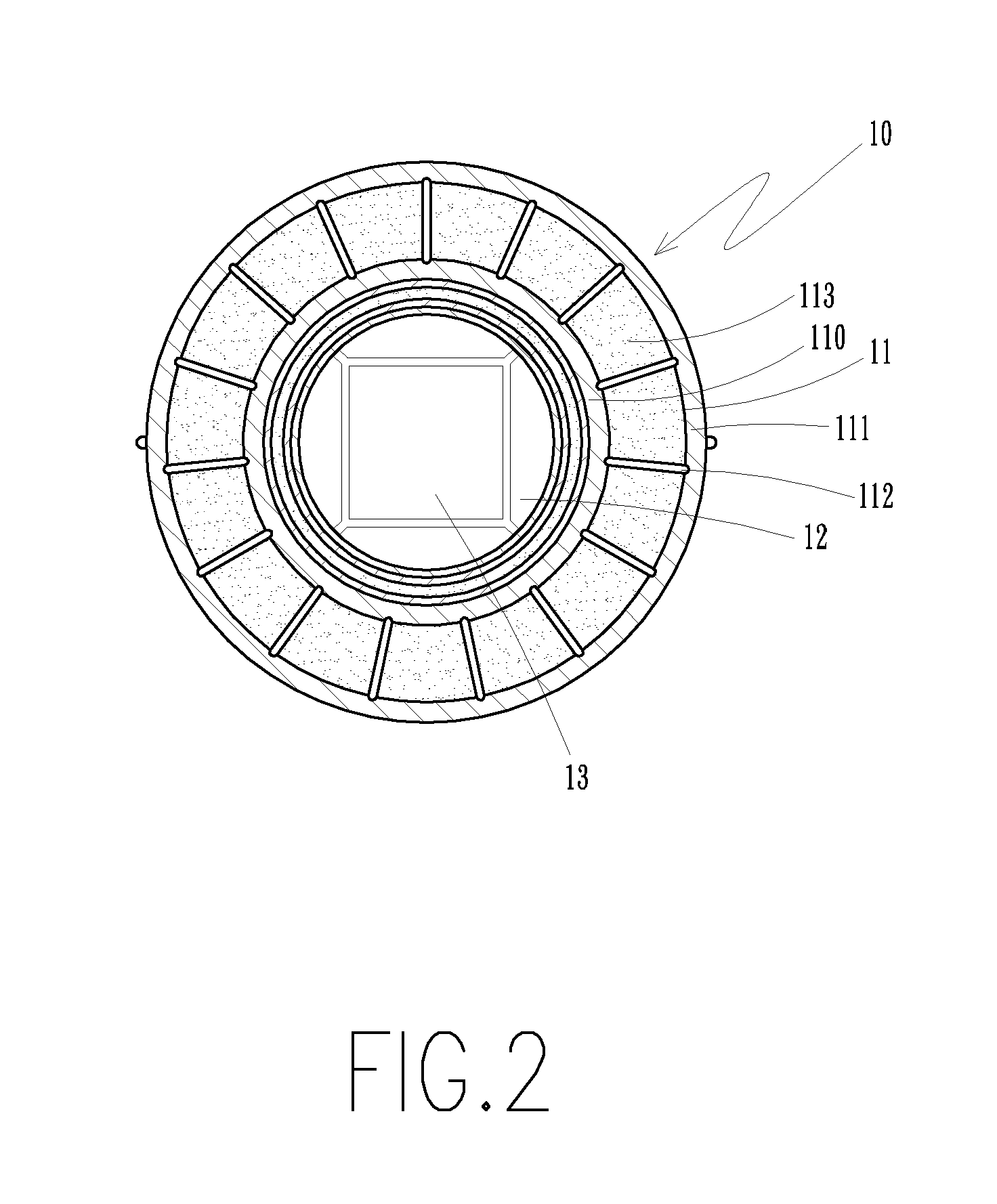

[0031]As shown in FIG. 1 and FIG. 2, the stove structure of the present invention comprises a stove body (10) and a cover (20).

[0032]The stove body (10) has at least one wall portion (11). The stove body (10) comprises a plurality of heat source portions (12) and a heating portion (13). The wall portion (11) has an inner wall (110) and an outer wall (111). The inner wall (110) and the outer wall (111) are connected by means of a plurality of cross-section conducting members (112). The connection is in the way of float-embedding or spot welding. The cross-section conducting members (112) have a U-like shape, wavy shape, spring coil shape or linear shape (not shown in the drawings). Between the inner wall (110), the outer wall (111) and the cross-section conducting members (112) is provided with a low conductivity coefficient member (113). The low condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com