Fan wheel for a blower module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

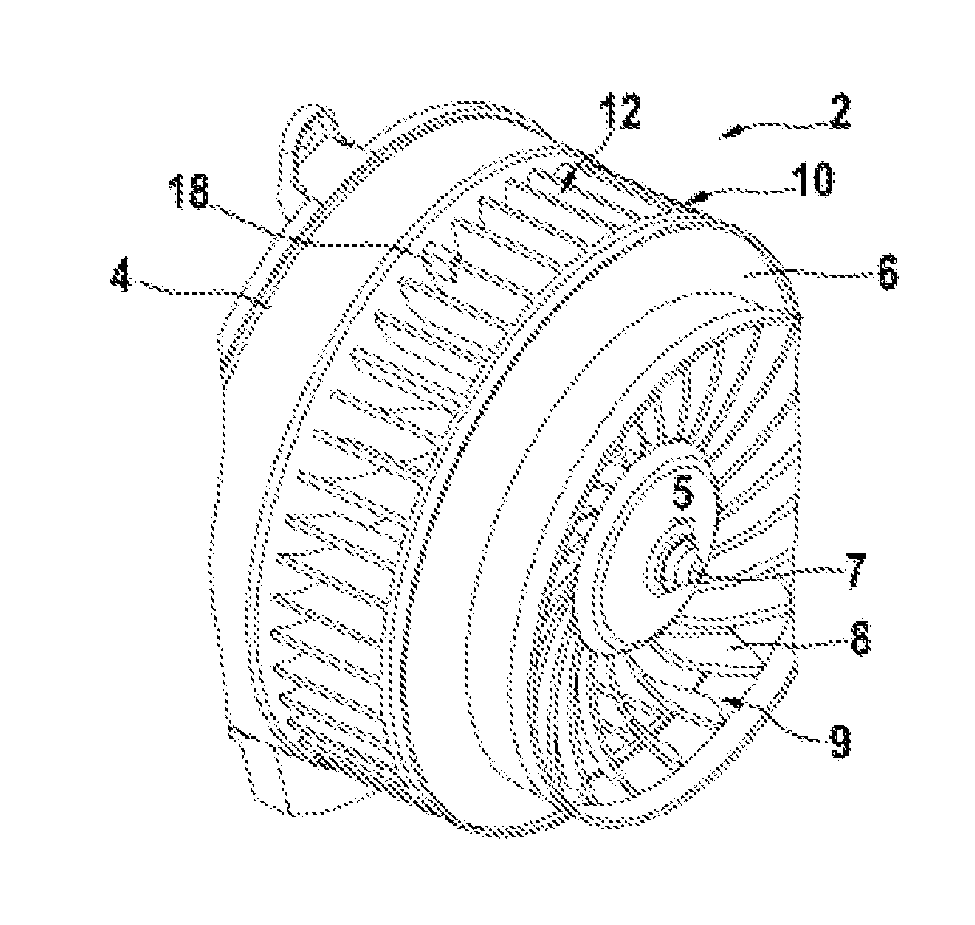

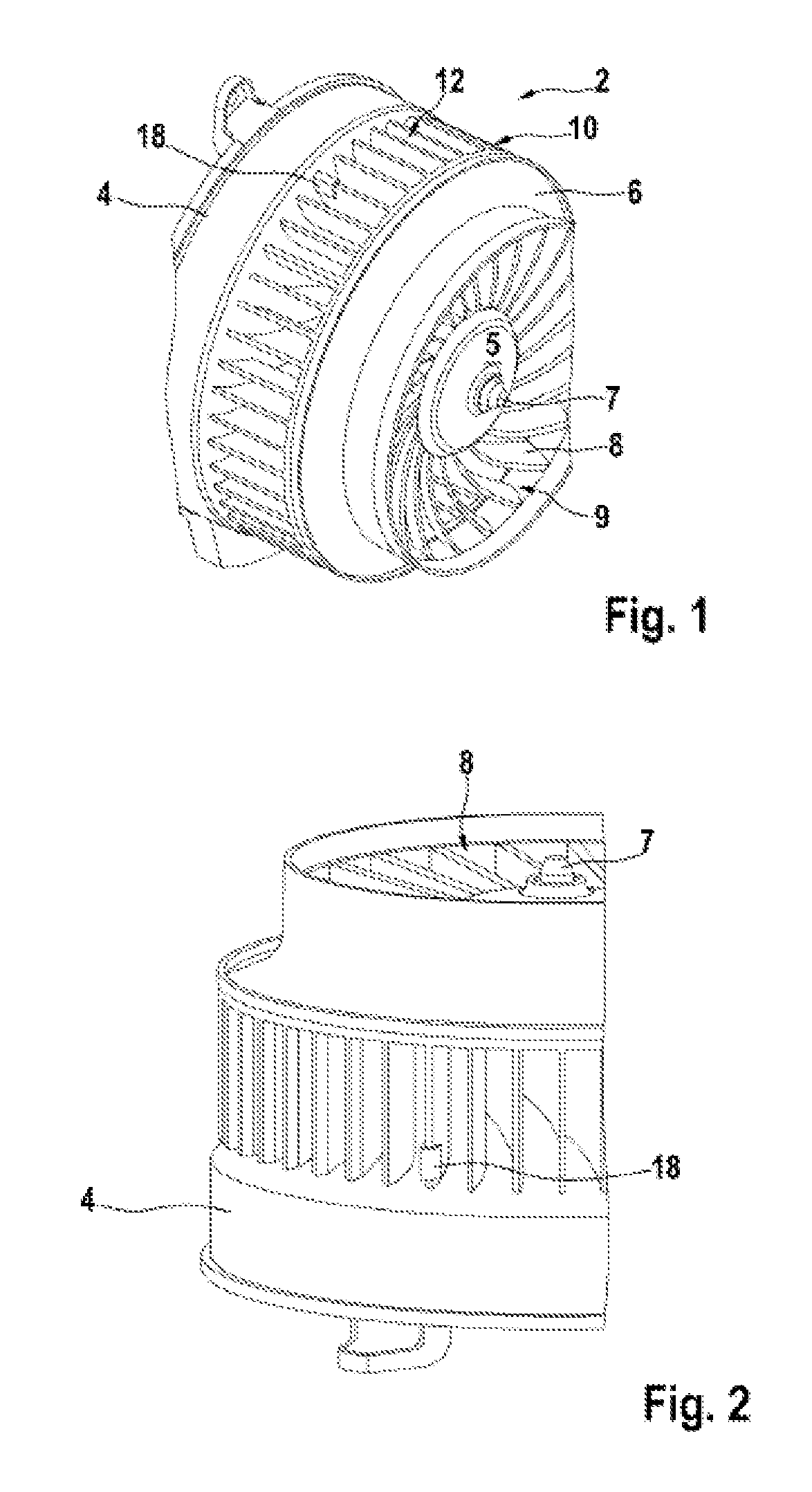

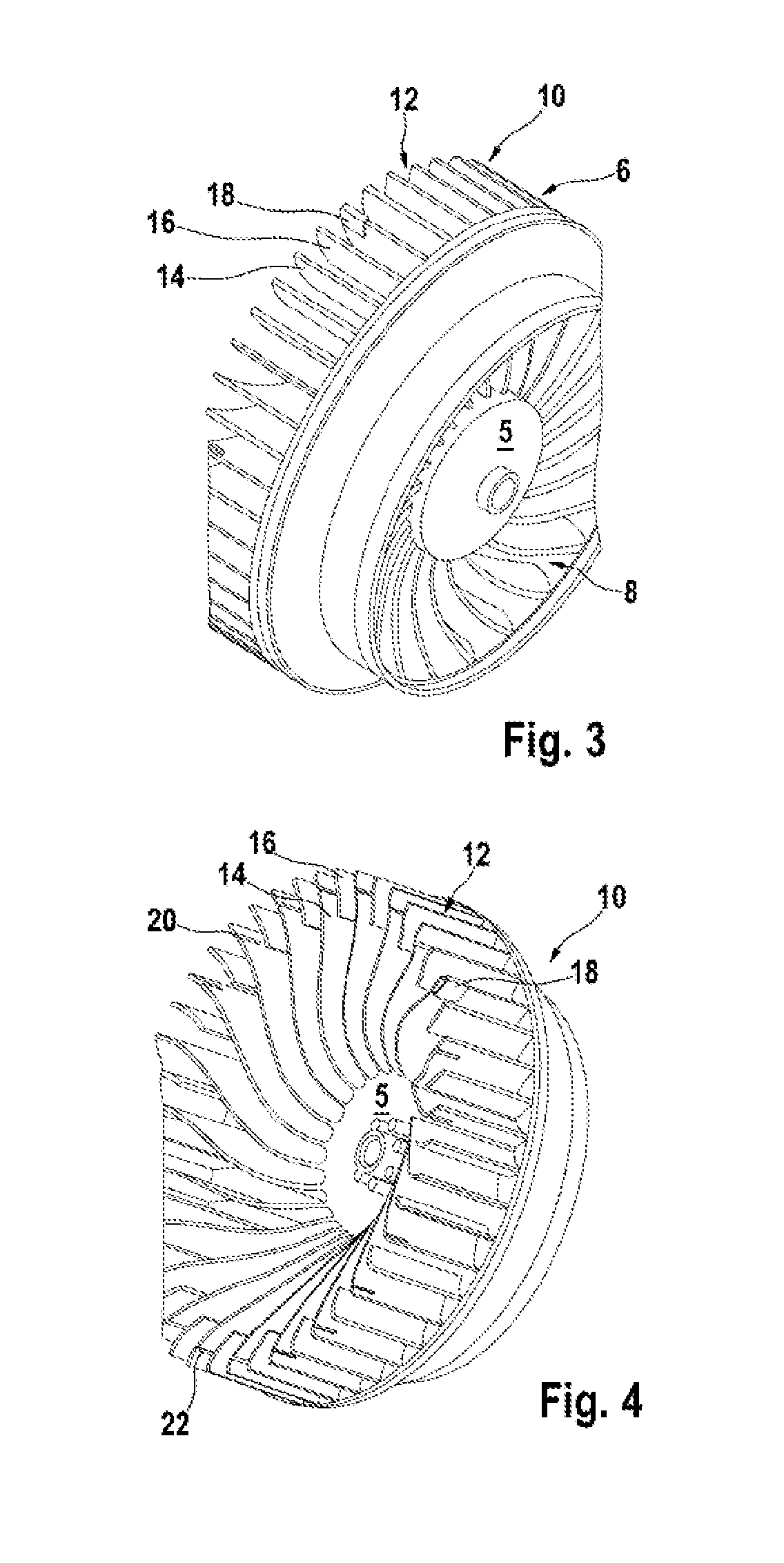

[0020]The blower module 2 illustrated in FIG. 1 comprises a basic housing 4, on which a fan wheel 6 is mounted such that it can be rotated on a drive shaft 7. The fan wheel 6, in turn, is fastened on the drive shaft 7 by way of its hub 5. The (radial) fan wheel 6 has, on its outer end side, an axial fan ring 8, which is made up of curved fan blades 9. The (radial) fan wheel 6 also has a radial fan ring 10, which is likewise made up of curved fan blades, referred to hereinbelow as radial fan blades 12. As can be seen from FIG. 4, the radial fan ring 10 has two different types of fan blade 12. A first group comprises long fan blades which extend as far as the hub 5, and will be referred to hereinbelow as long fan blades 14, whereas a second group comprises short fan blades 16 which, as seen from the external diameter of the radial fan ring 10, extend only some way in the direction of the axis of rotation. The two groups of fan blades 14, 16 are formed alternately on the (radial) fan w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com