Dairy animal milking preparation system and methods

a technology for dairy animals and preparation systems, applied in the field of dairy animal teat preparation, rinsing, and milking, can solve the problems of failure of attachment attempts, faster milking, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124]To the extent reasonable and practical, the same identification numeral will be used to identify the same or similar feature in each of the figures.

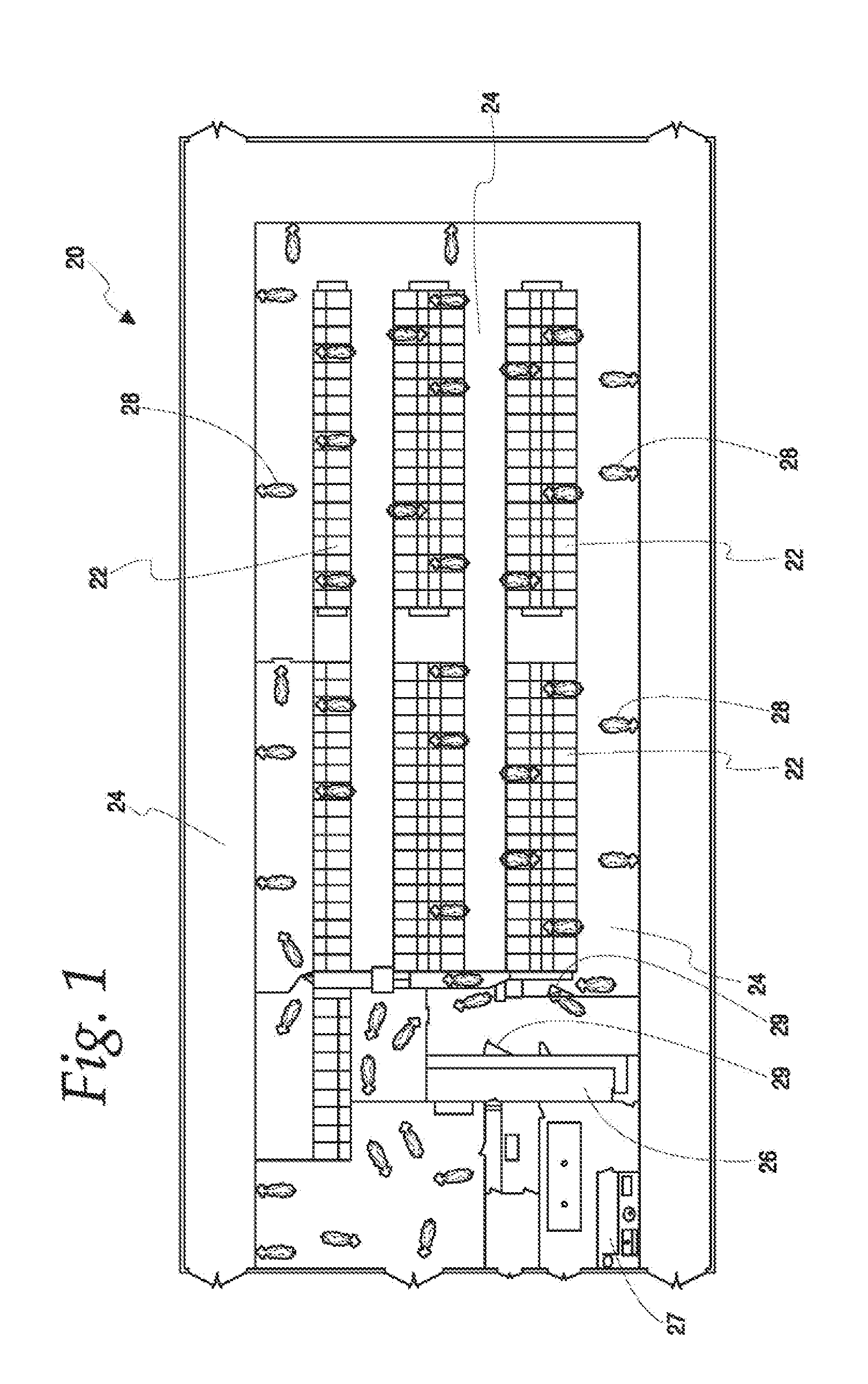

[0125]Illustrated generally in FIG. 1 is a dairy harvesting facility 20 having stalls 22, alleys 24, and milking stalls 26. Dairy animals 27 move through the dairy harvesting facility 20 to feed, rest, and be milked in the milking stalls 26. Control gates 29 can be used to sort cows or to prevent them from entering a particular area. Preferably, an animal identification system is used to identify cows for sorting and correlating to milk, illness, and other purposes.

[0126]The milking stalls 26 can be of any shape or arrangement, and be stationary or rotatable. Animals can be allowed to enter the milking stalls at will or be controlled by gates 29 that are selective based on the animal's history of milking or health considerations. Animals can also be moved into the milking stalls 26 by an operator.

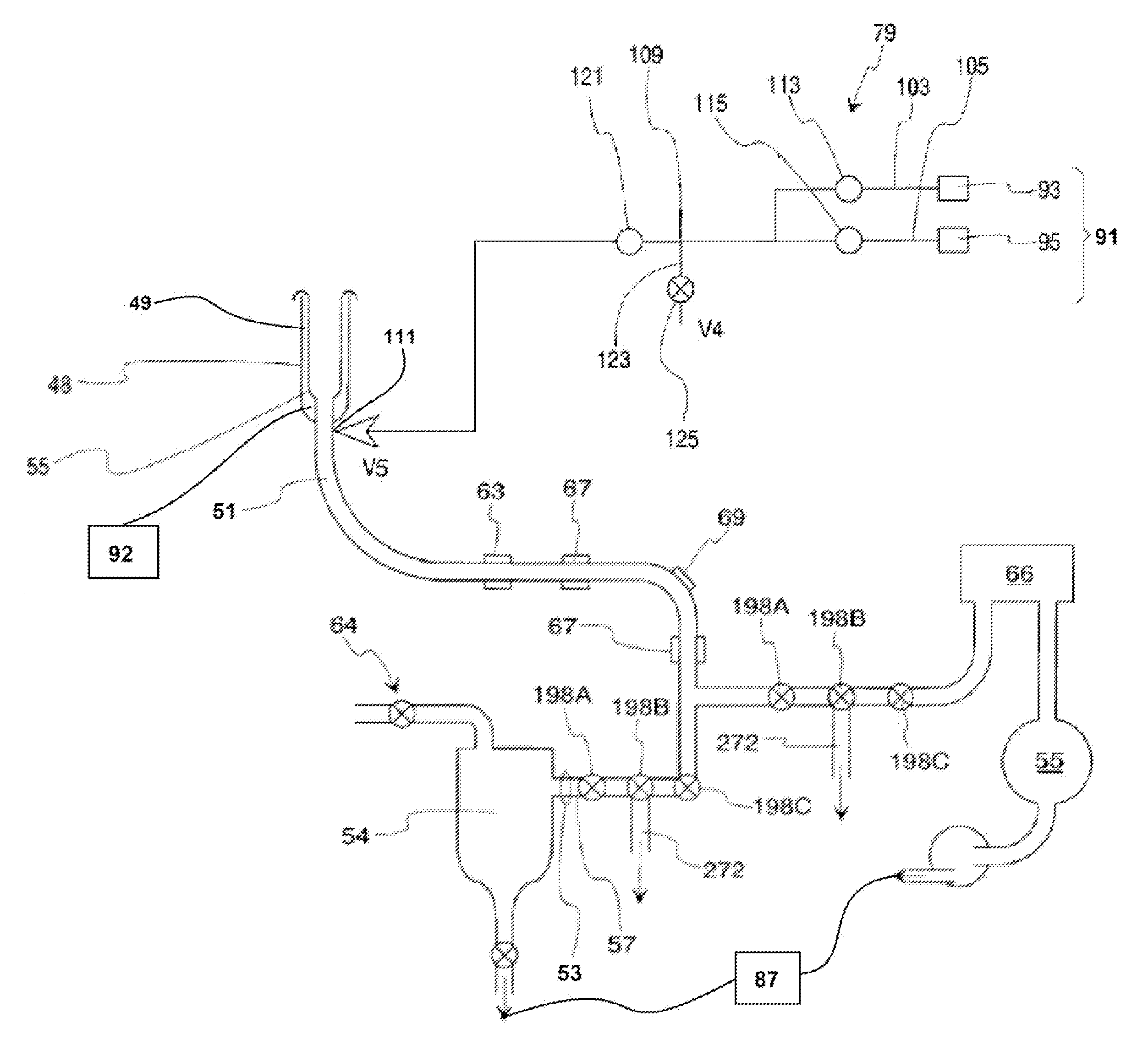

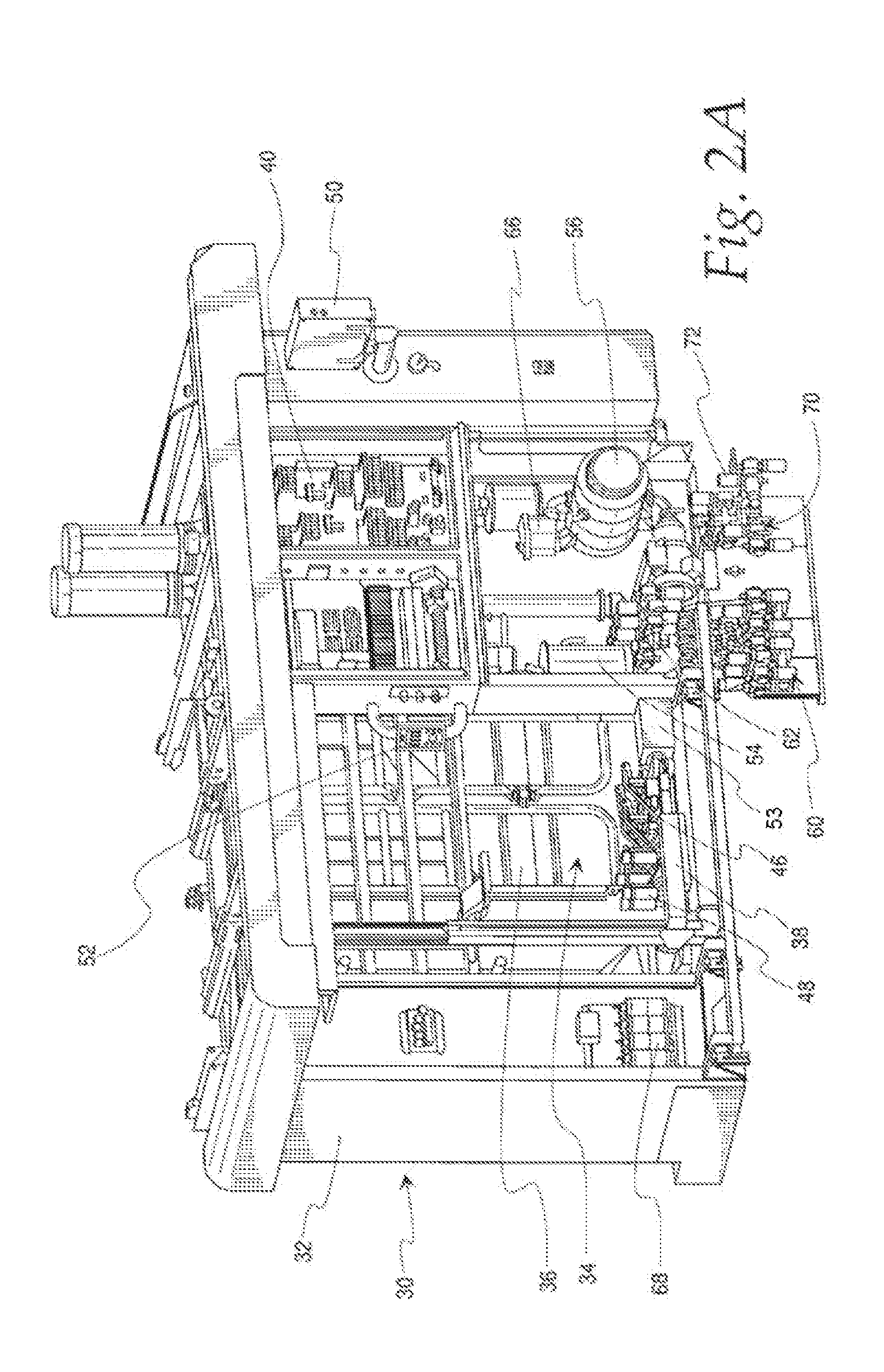

[0127]In a preferred embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com