System for using flue gas heat

a flue gas heat and heat exchange technology, applied in the direction of drying machines, drying, lighting and heating apparatus, etc., can solve the problems of transfer of very high temperature regenerators and additional cost, and achieve the effect of reducing the requirement and reducing the cost of the requiremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

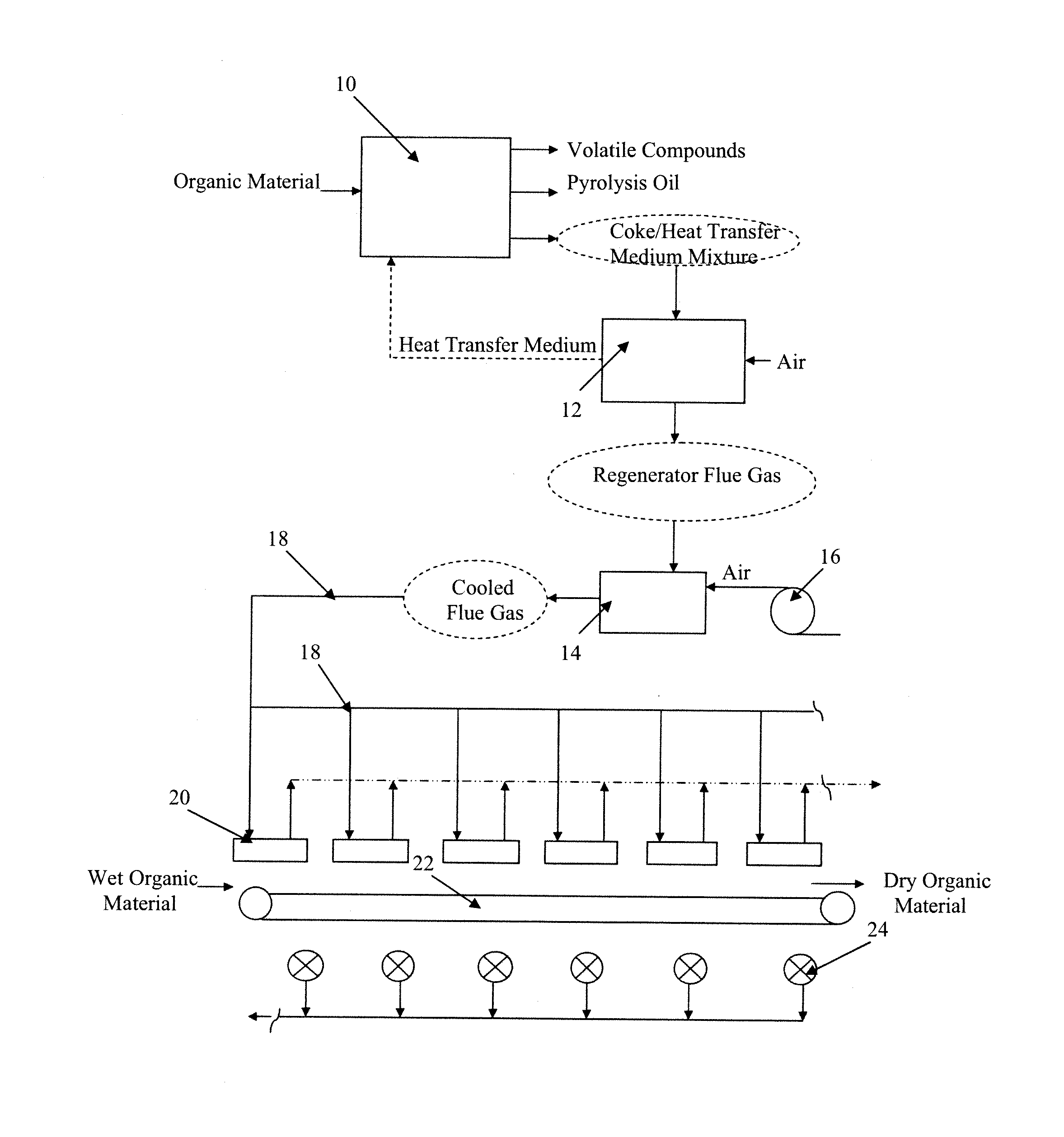

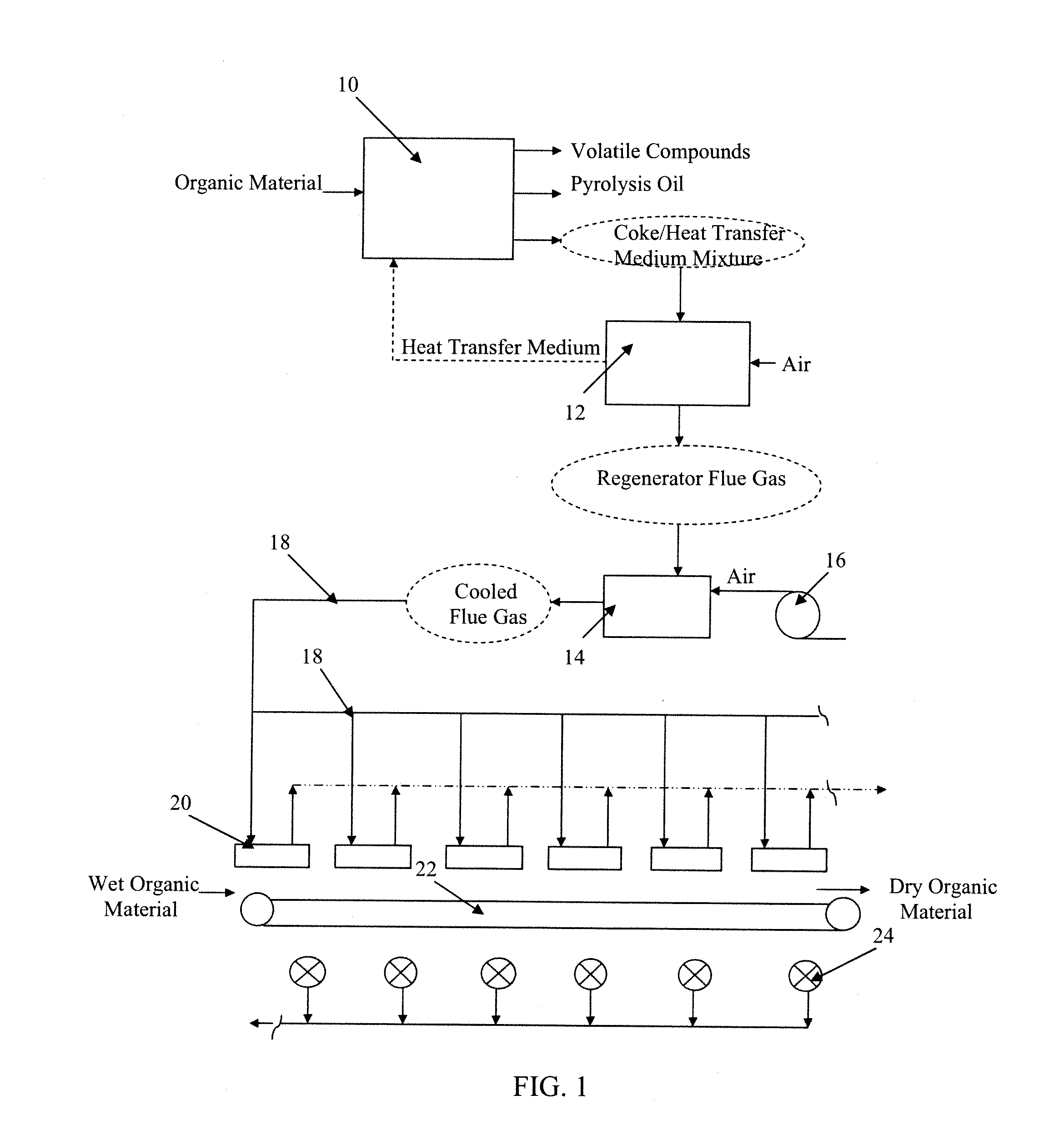

[0014]In general terms one embodiment of the present invention pertains to a process for pyrolysis and drying of organic material. The organic material may be any suitable material that is capable of being pyrolyzed. The type of material selected may, of course, vary depending upon, for example, the desired products and / or their desired use. Since in one embodiment the present invention also assists in drying the starting organic materials, the present invention may be most advantageous when pyrolyzing materials that may need to be at least partially dried before undergoing pyrolysis. Such materials may include, for example, coal, biomass, and / or mixtures thereof.

[0015]Typically, useful biomass includes any cellulosic or lignocellulosic material and includes materials comprising cellulose, and optionally further comprising hemicellulose, lignin, starch, oligosaccharides and / or monosaccharides. Biomass may also comprise additional components, such as protein and / or lipid. Biomass may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com