Touch module

a module and touch technology, applied in the field of touch modules, can solve the problems of increasing material cost, noise, complicated manufacturing procedure, etc., and achieve the effect of reducing material cost and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

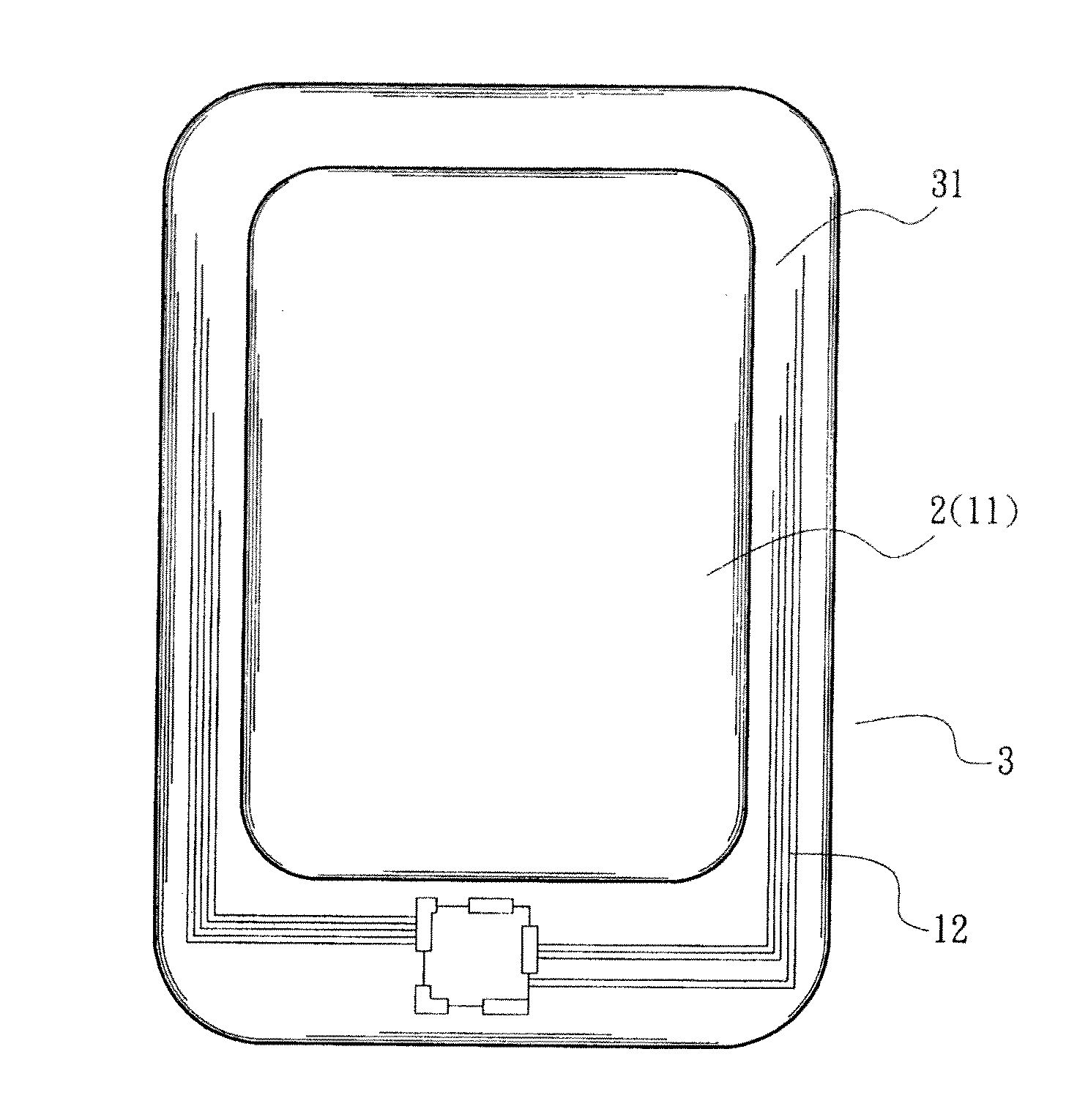

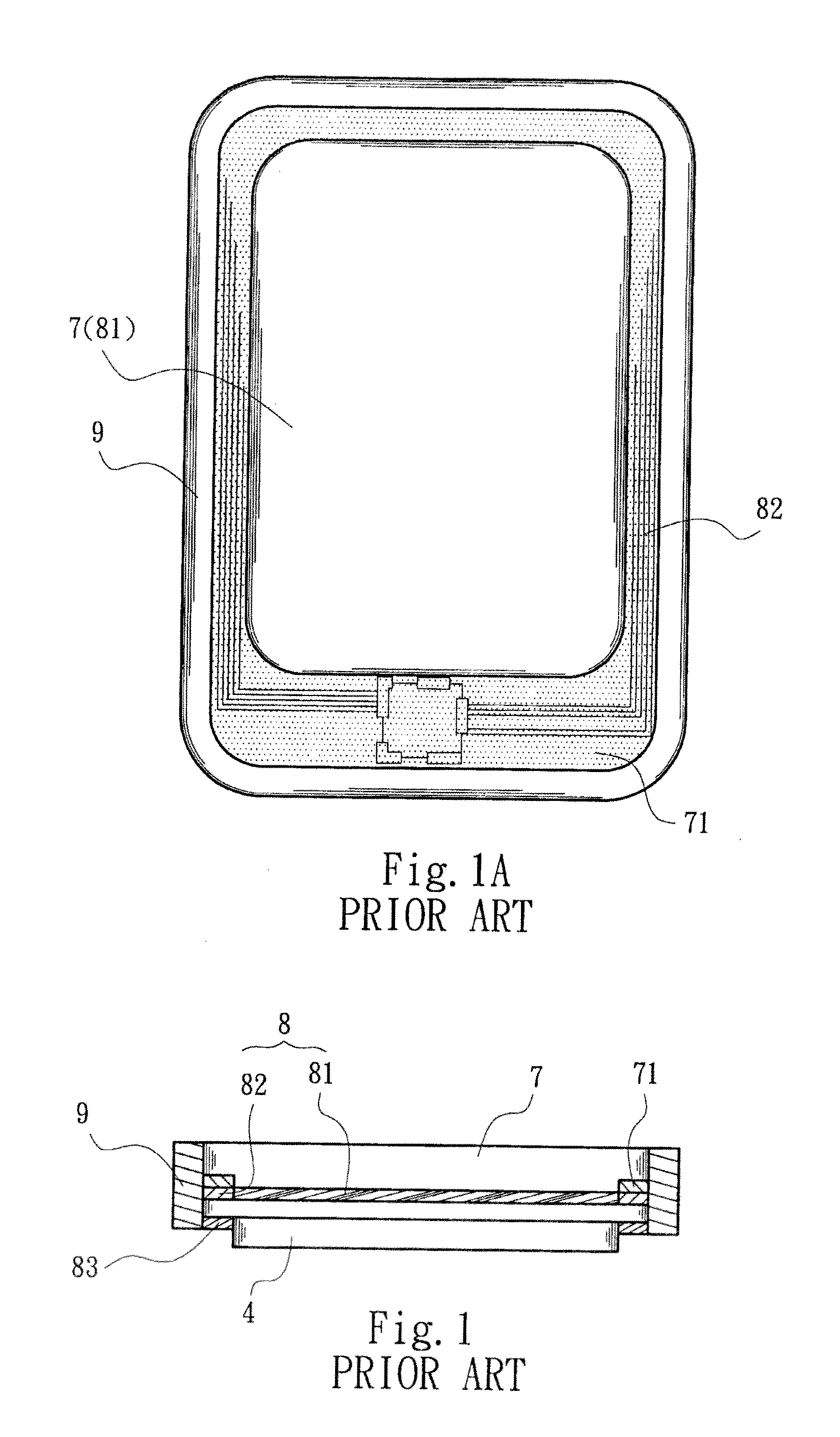

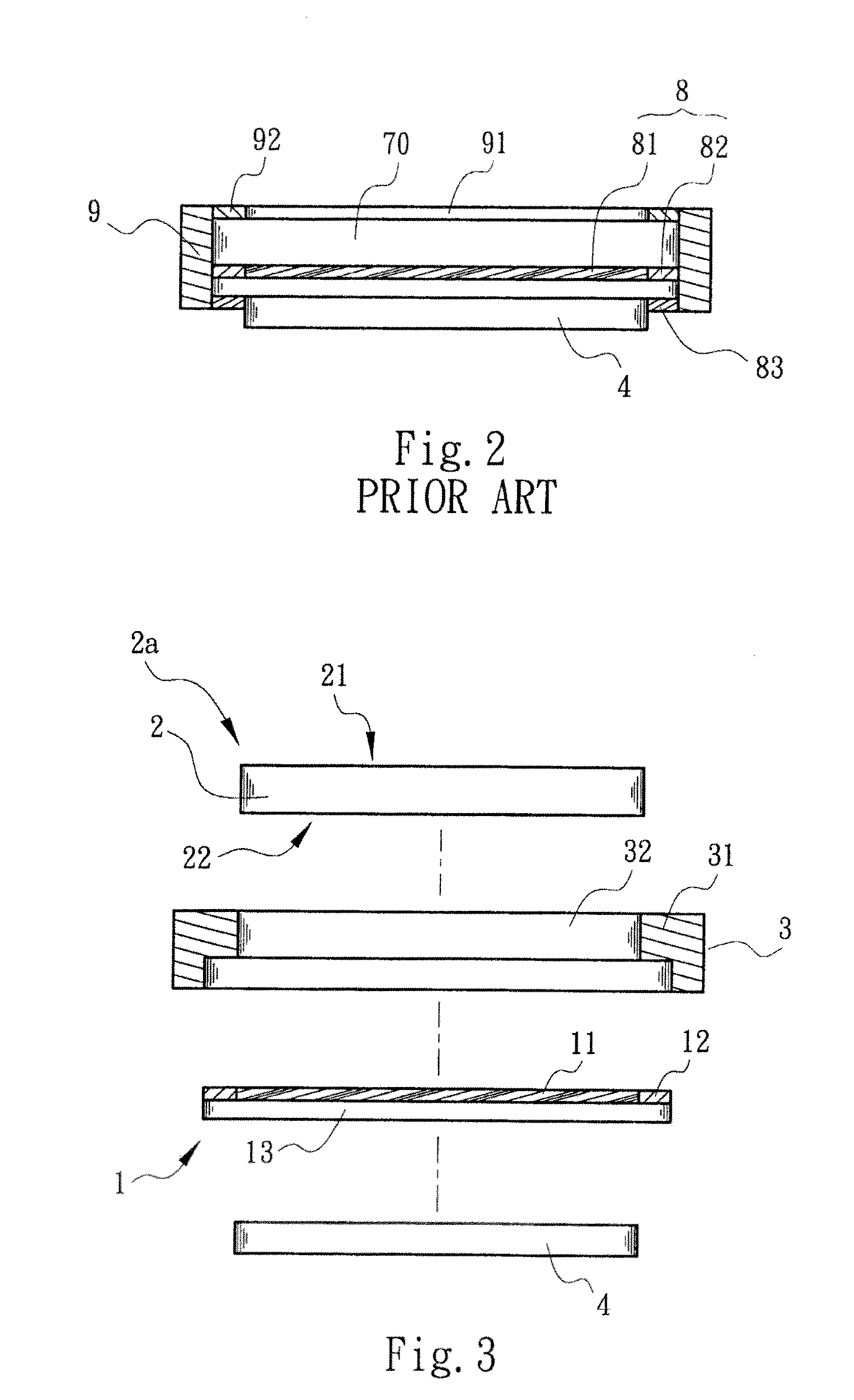

[0038]Please refer to FIGS. 3 to 3B. the touch module of the present invention mainly includes a touch layer 1, a transparent panel module 2a and a case 3. The touch layer 1 is composed of multiple sensors 11 for sensing the touch and a connection circuit 12 arranged around the sensors 11. The multiple sensors 11 and the connection circuit 12 can be formed on a sheet-shaped transparent protective element 13 as necessary.

[0039]In this embodiment, the transparent panel module 2a is a one-piece transparent panel 2 made of transparent material. The transparent panel 2 has a first side 21 and a second side 22 opposite to the first side 21. The second side 22 is directly bonded with the sensors 11 of the touch layer 1. The connection circuit 12 is formed along at least a part of the periphery of the transparent panel 2. In practice, a liquid crystal module layer 4 is additionally disposed under the sensors 11 of the touch layer 1. The liquid crystal module layer 4 not only serves to disp...

fourth embodiment

[0045]Please refer to FIGS. 6 and 6A, which show the present invention. According to the fourth embodiment, the touch module of the present invention includes a touch layer 1 and liquid crystal module layer 4 as in the first embodiment. The fourth embodiment further includes a transparent panel module 6a and a case 30. In this embodiment, the transparent panel module 6a is a one-piece transparent panel 6 made of transparent material. The transparent panel 6 has a first side 61 and a second side 62 opposite to the first side 61. The first side 61 includes at least one first surface 611 and at least one second surface 612. The first and second surfaces 611, 612 are positioned on different levels of the transparent panel 6. The second side 62 has a sensing section 621 corresponding to and opposite to the first surface 611 and a wiring section 622 corresponding to and opposite to the second surface 612. The sensing section 621 and the wiring section 622 of the second side 62 of the tran...

sixth embodiment

[0047]Please refer to FIG. 8, which show the present invention. According to the sixth embodiment, the touch module of the present invention includes a touch layer 1, a case 300, a liquid crystal module layer 4 and a transparent panel module 6a as in the fourth embodiment. The transparent panel module 6a (transparent panel 6) is fixed in the opening of the case 300. The other components of the touch layer 1 and the liquid crystal module layer 4 are totally identical to those of the fourth embodiment in structure and positional relationship. The sixth embodiment is only different from the fourth embodiment in that the sixth embodiment further includes a transparent sheet 303 disposed in the opening of the case 300 over the transparent panel module 6a. The transparent sheet 303 serves as a protective shield in adaptation to the case 300 with a different configuration for achieving better waterproof protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com