Composite plate and armor having at least one of the composite plates

a composite plate and composite plate technology, applied in the field of composite plate and armor having the composite plate, can solve the problems of significant decrease in the energy and deflection of the projectile, decrease in the penetration capacity of the projectile, etc., and achieve the effect of simplifying the assembly of the first layer, reducing the kinetic energy of the projectile, and strengthening the armor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

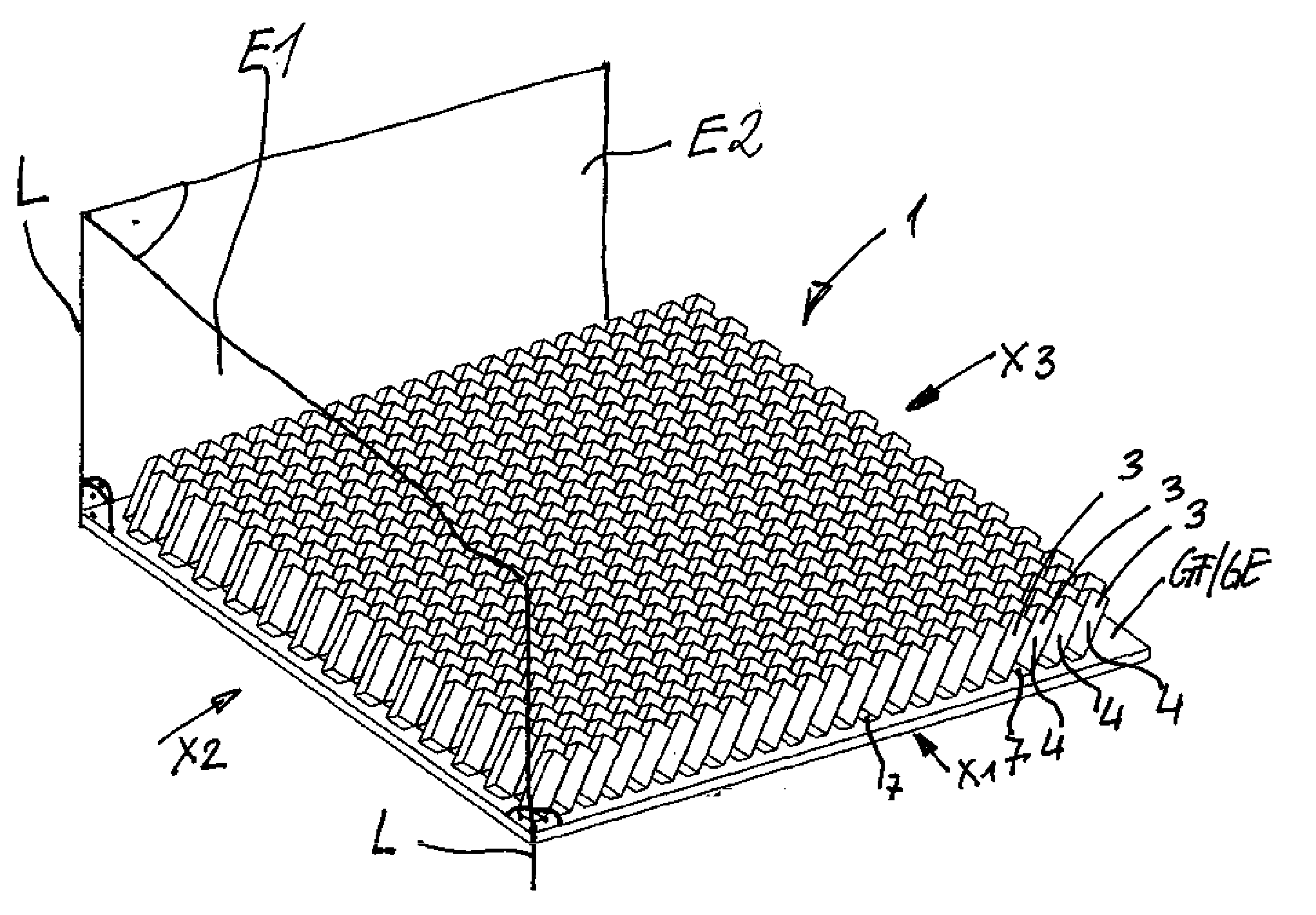

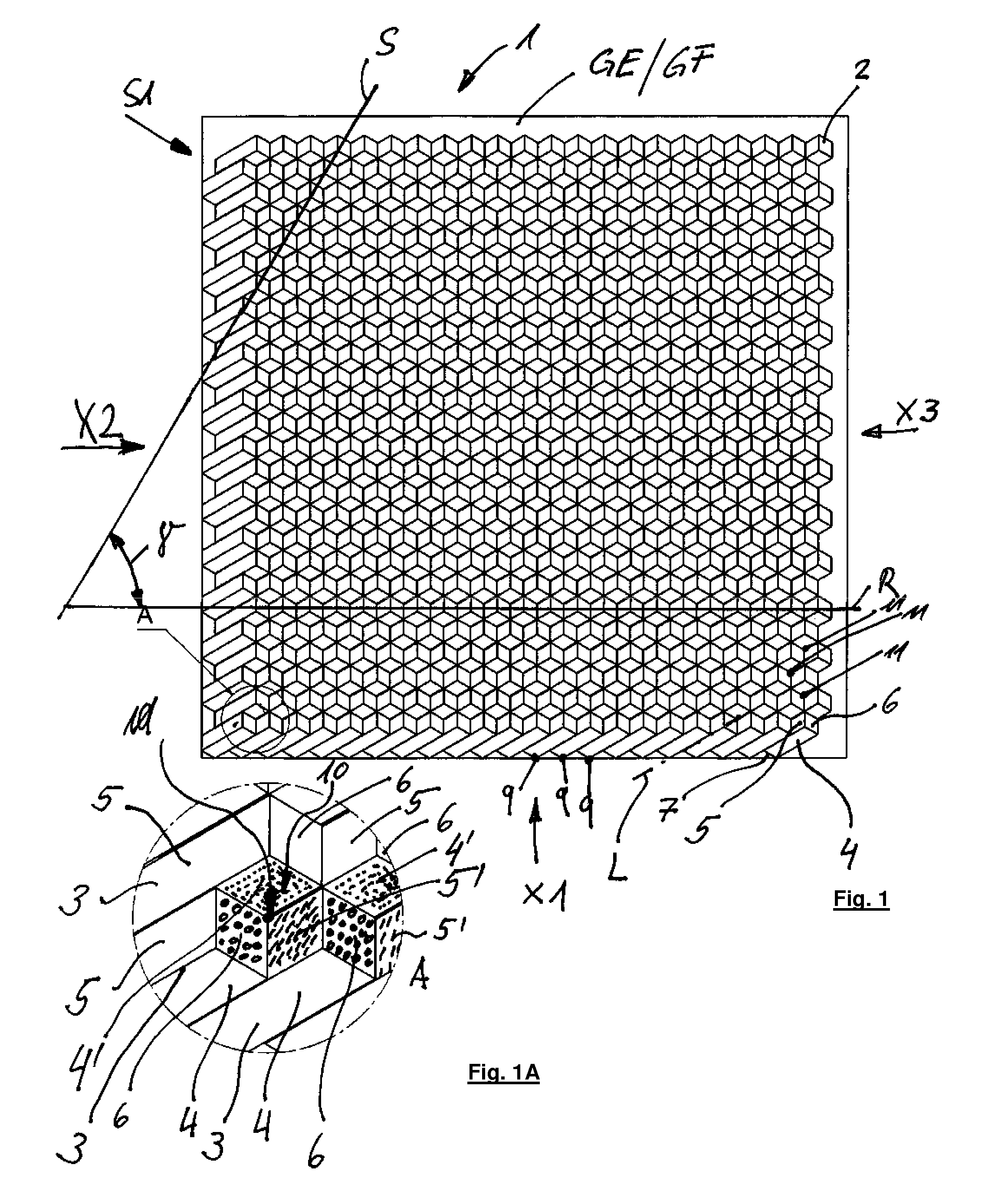

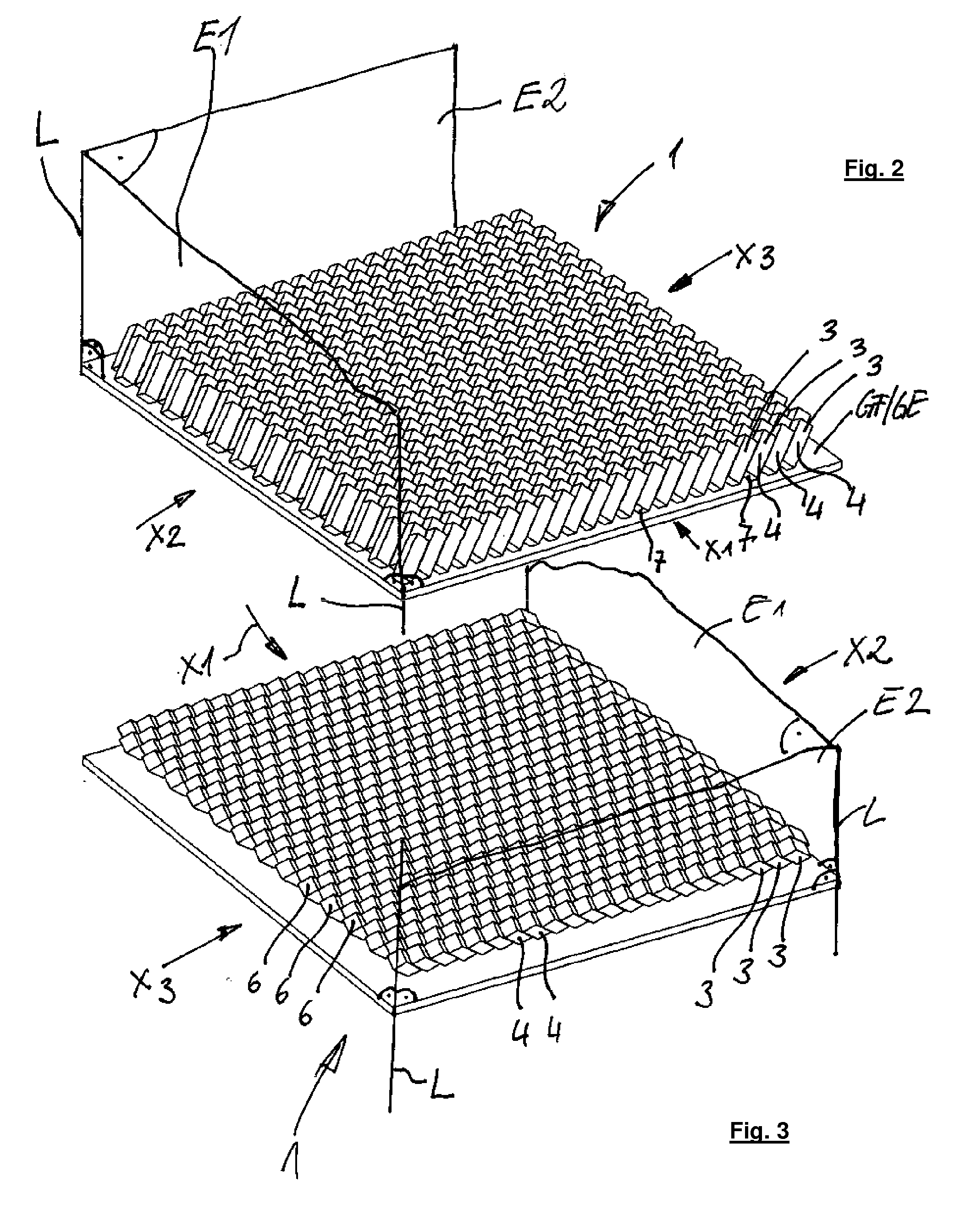

[0091]In a first embodiment (FIGS. 1 through 6), a composite plate 1 according to the invention has at least one first layer S1 for deflecting a projectile 12; the layer S1 is composed of a multitude of ceramic molded components 2 situated adjacent to one another in rows R and columns S.

[0092]In a top view of the composite plate 1 according to the invention shown in FIG. 1, the columns S enclose an angle α with the rows R. The composite plate 1 according to the invention is essentially a flat structure. For the sake of clarity, in FIG. 1 and in various figures below, a basal plane GE is indicated that is essentially intended to illustrate the three-dimensional space of the composite plate 1. The basal plane GE should not be viewed as another layer of the composite plate 1.

[0093]It is naturally also possible to construct the composite plate using basal surfaces other than a basal plane, e.g. arched and / or bossed basal surfaces.

[0094]According to the invention, the ceramic molded comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com