Universal Subsea Oil Containment System and Method

a technology of oil containment system and subsea oil, applied in the field of oil and gas systems, can solve the problems of life loss, limited solutions, and roughly thirty-year technology gap that exists

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

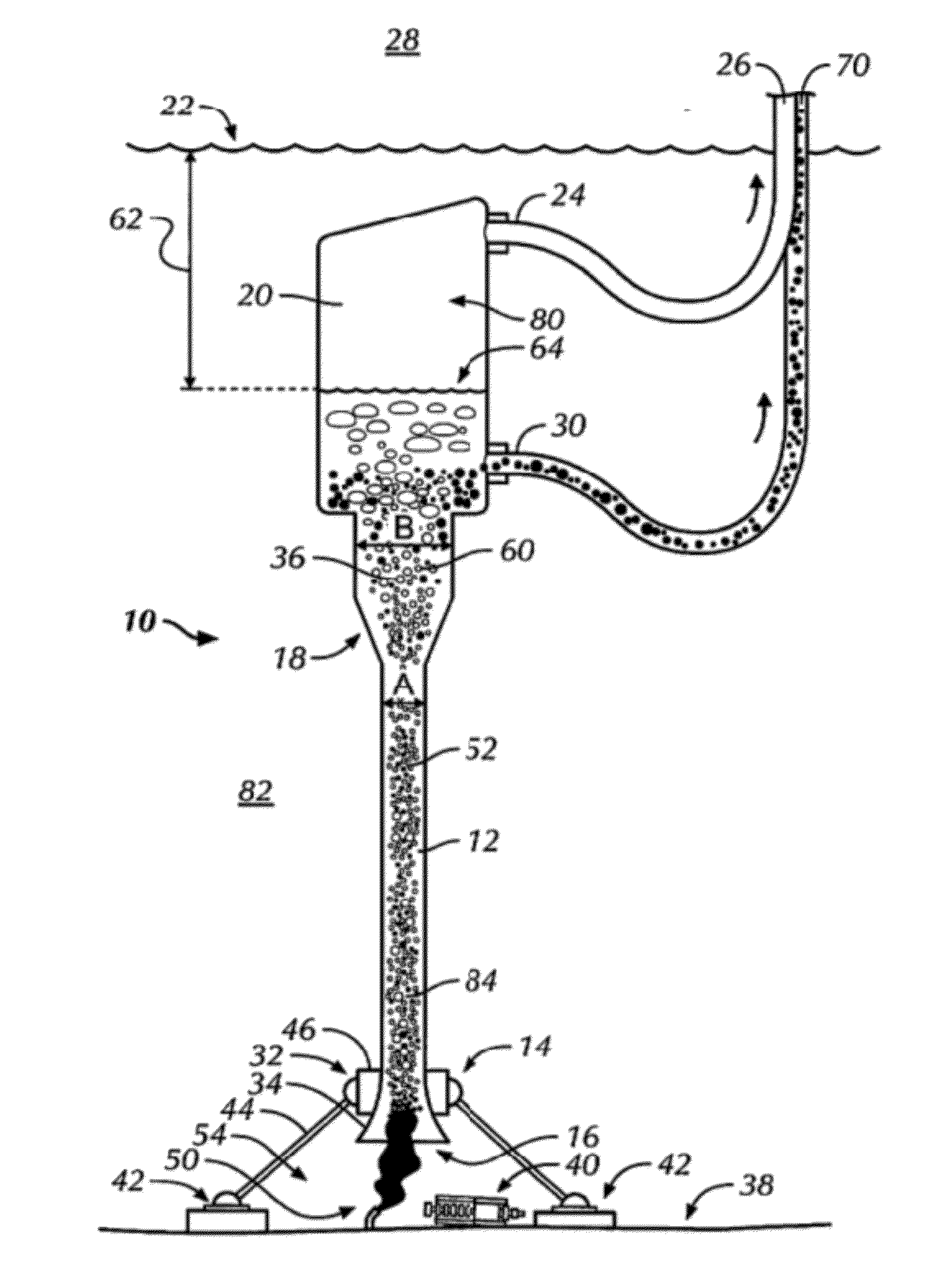

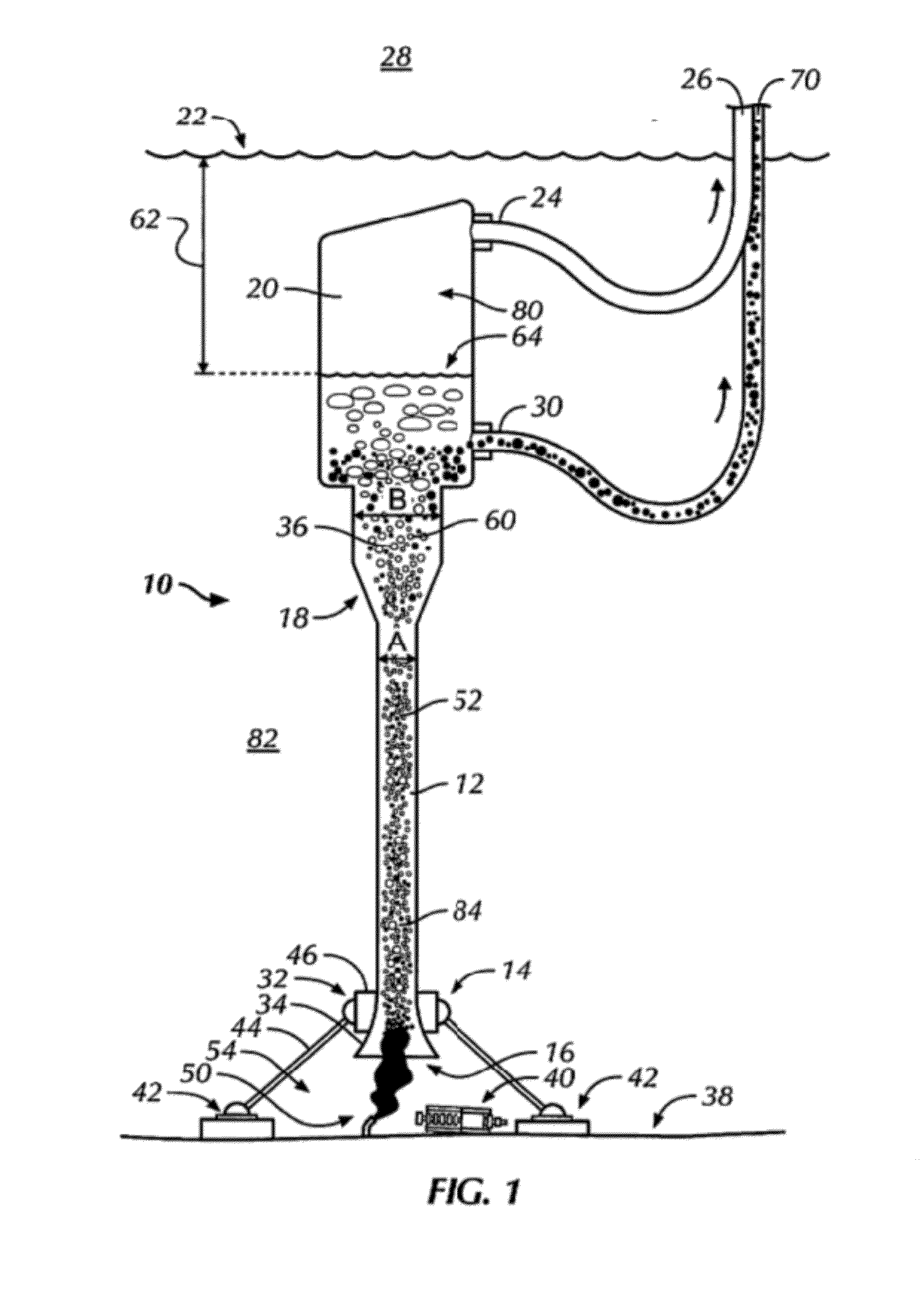

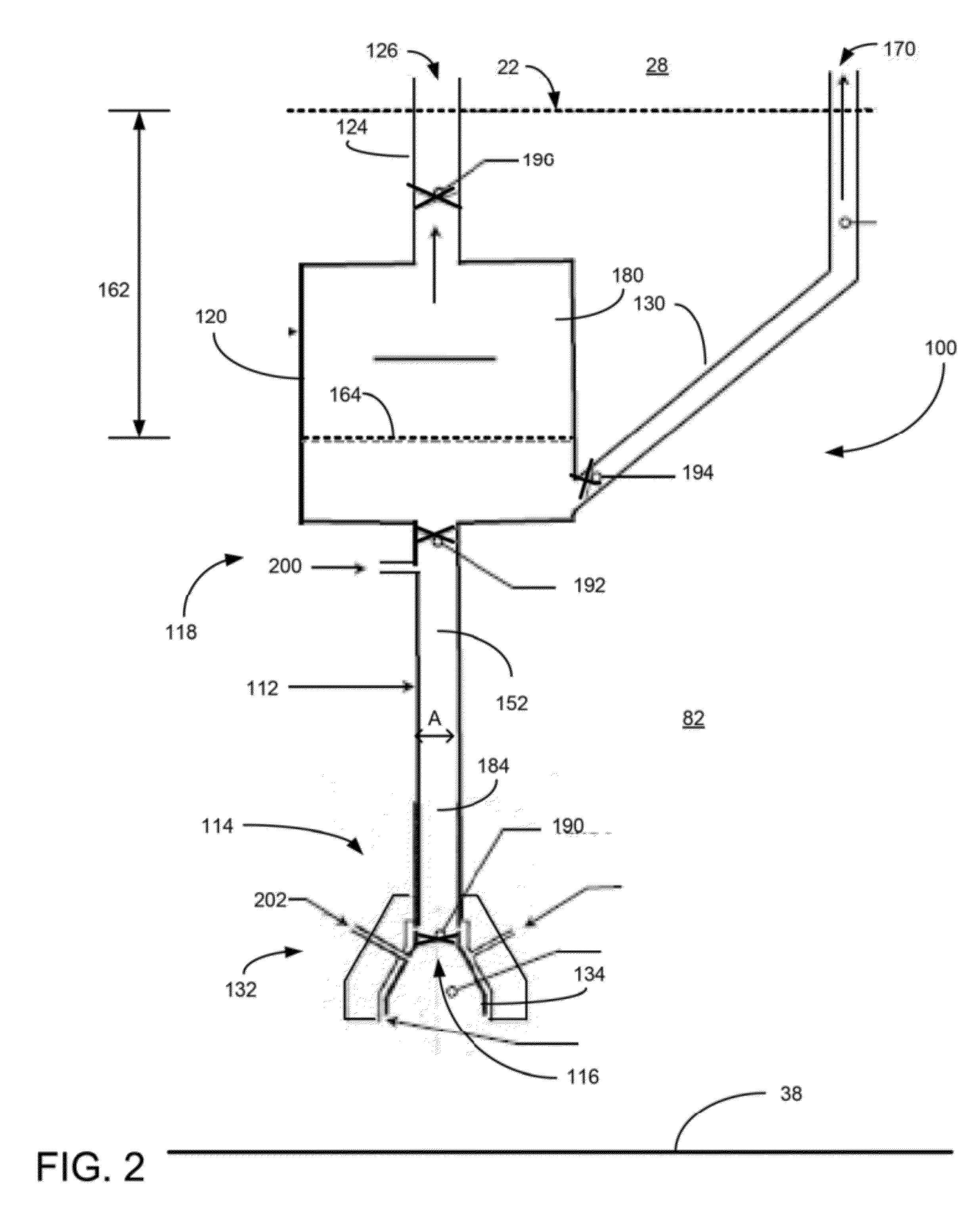

[0017]The present invention is a system and method of capturing and containing oil and gas leaking from an underwater man-made structure. FIG. 1 is a side view of a containment system 10 in one embodiment of the present invention. The containment system 10 includes a main conduit 12 having a first lower end 14 with an opening 16 and an opposite second upper end 18 with a containment tank 20. In one embodiment, the containment tank may be located below a seawater surface 22. In this embodiment, the containment tank may be coupled to a gas release tube 24 leading to the surface 22. The tube 24 may lead to an aperture 26 opened to the outside above-water environment 28 or to a man-made structure such as a ship (not shown). Flow control devices, such as fixed (e.g., Venturi) or variable (e.g., valves) may be used to control the flow of the gas exiting the tube. The containment tank may also include a second liquid ejection tube 30 having a pump (not shown) leading to the surface 22 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com