Electroplating method

a technology of electroplating and film filling, which is applied in the direction of sealing devices, contact devices, coatings, etc., can solve the problems of time required, difficulty in attempting to meet ideal requirements, and conventional electroplating processes have failed to achieve both ideal filling of plated films, etc., and achieve the effect of shortening the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

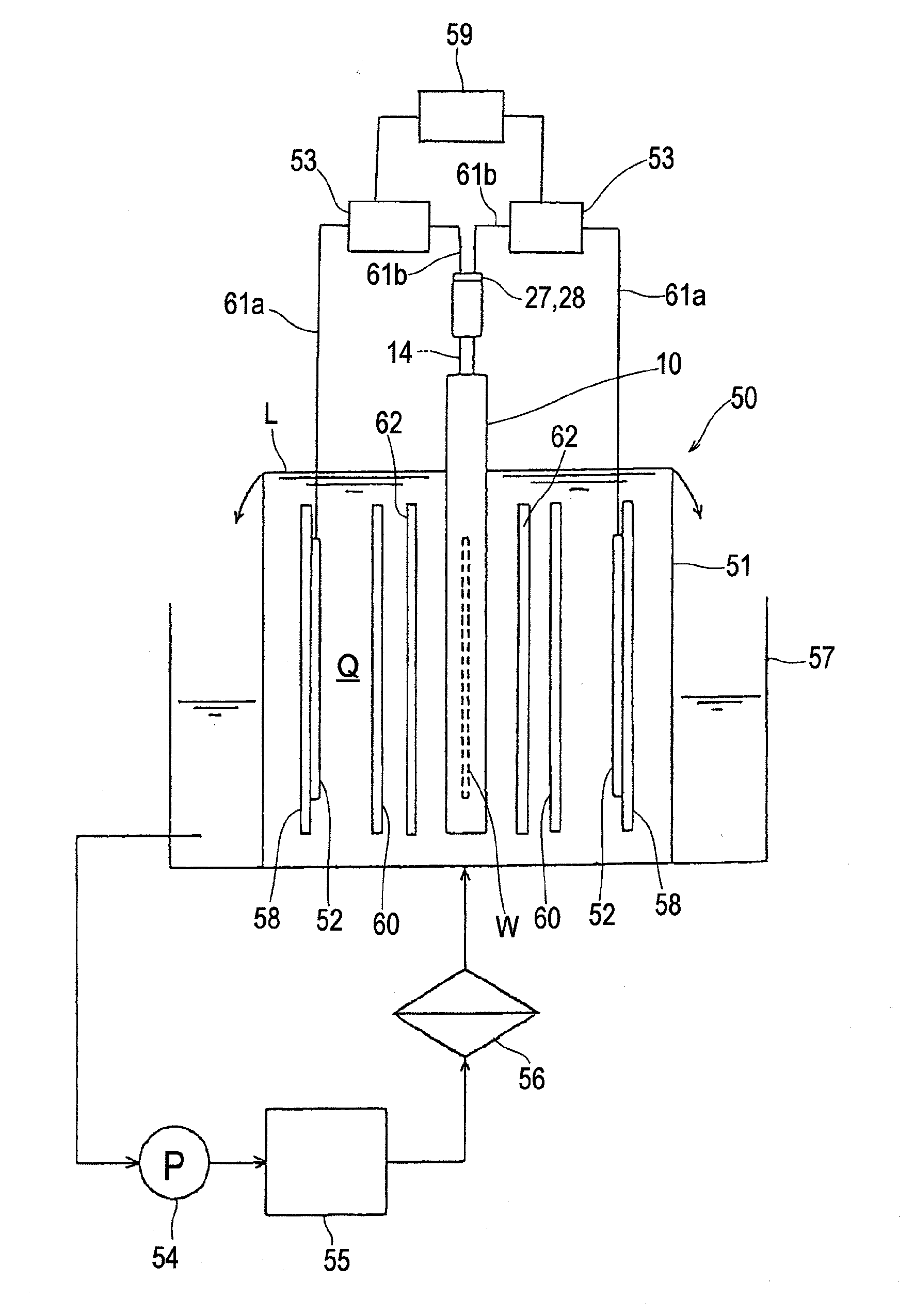

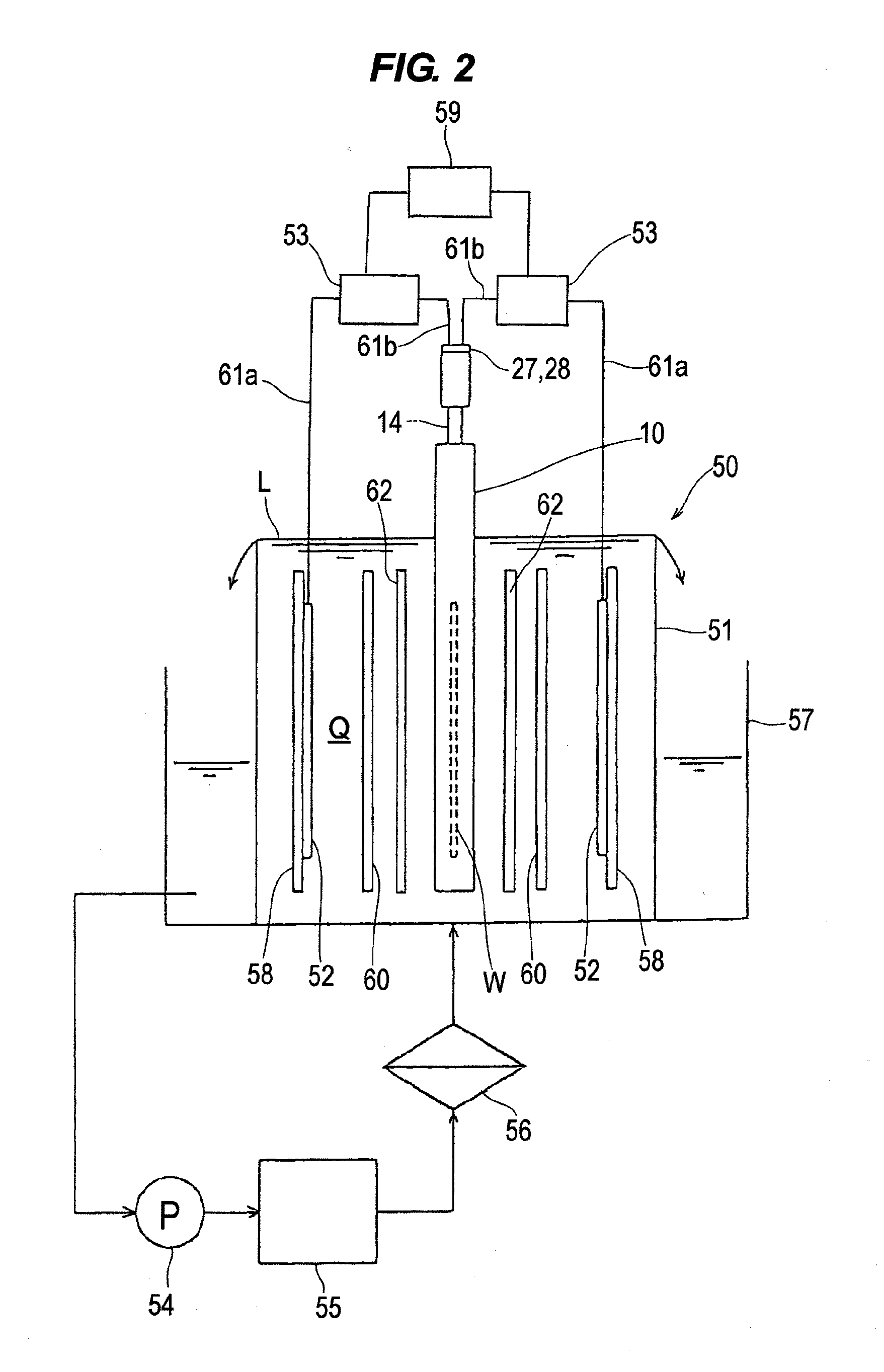

[0058]Preferred embodiments of the present invention will now be described with reference to the drawings. FIG. 2 is a vertical sectional front view schematically showing an electroplating apparatus 50 which is used to carry out an electroplating method according to the present invention. As shown in FIG. 2, the electroplating apparatus 50 includes a plating tank 51 holding a plating solution Q therein, and a substrate holder 10 holding a substrate W such as a semiconductor wafer or the like and suspended vertically in the plating solution Q. The plating solution Q with the substrate holder 10 immersed therein has a surface level L at the upper end of the plating tank 51, as shown in FIG. 2. Two insoluble anodes 52 supported on respective anode holders 58 are disposed in the plating tank 51 in facing relation to respective opposite surfaces, i.e., face and reverse sides, of the substrate W held by the substrate holder 10. As shown in FIG. 3, the substrate holder 10 includes a first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com