Valve timing regulator

a timing regulator and valve technology, applied in non-mechanical valves, valve arrangements, machines/engines, etc., can solve the problems of reducing the operating speed of the rotor and increasing the leakage rate, and achieve the reduction of the rotor operating speed, the effect of reducing the linear expansion coefficient, and enhancing the ease of attachment of the assist spring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

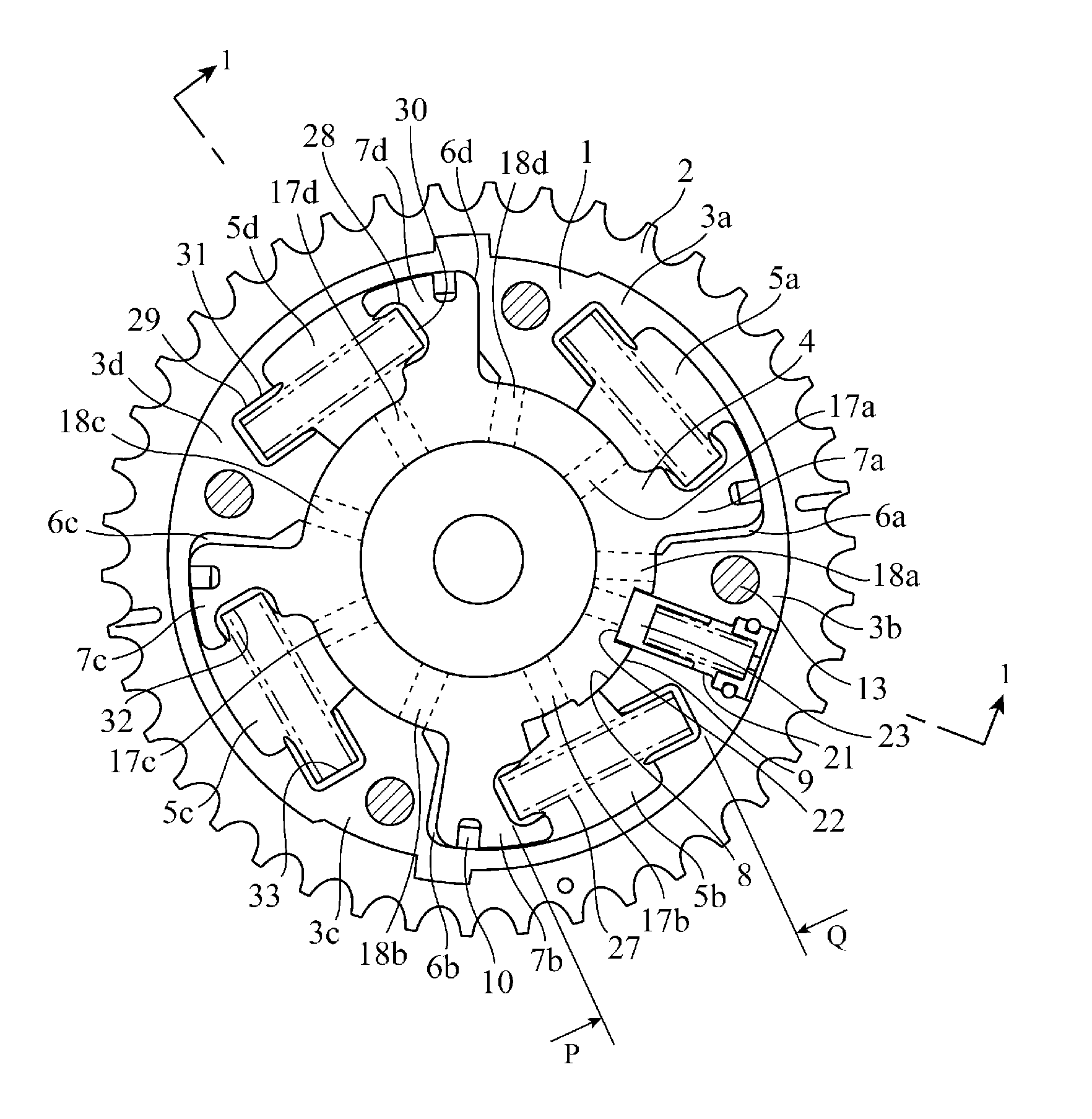

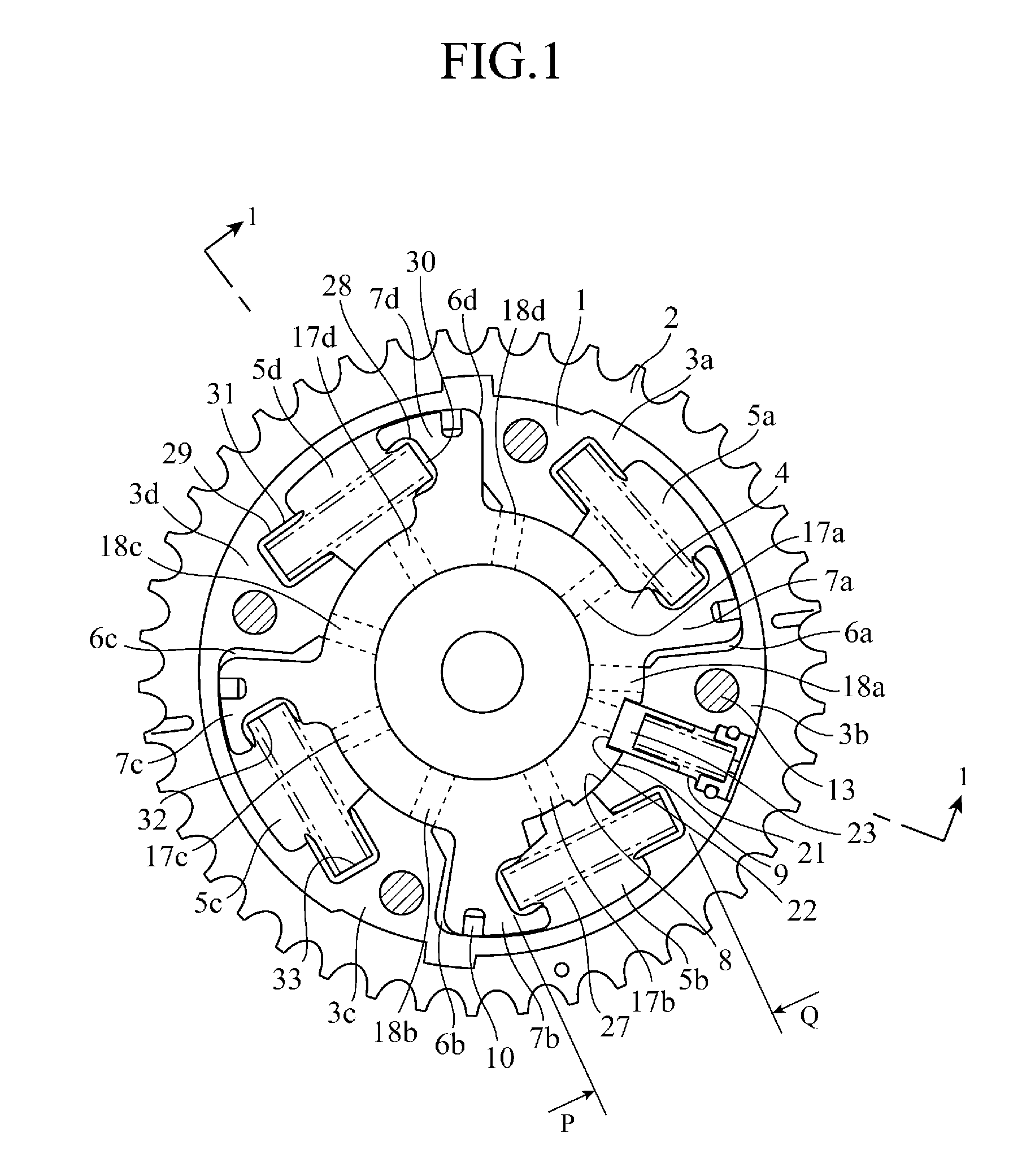

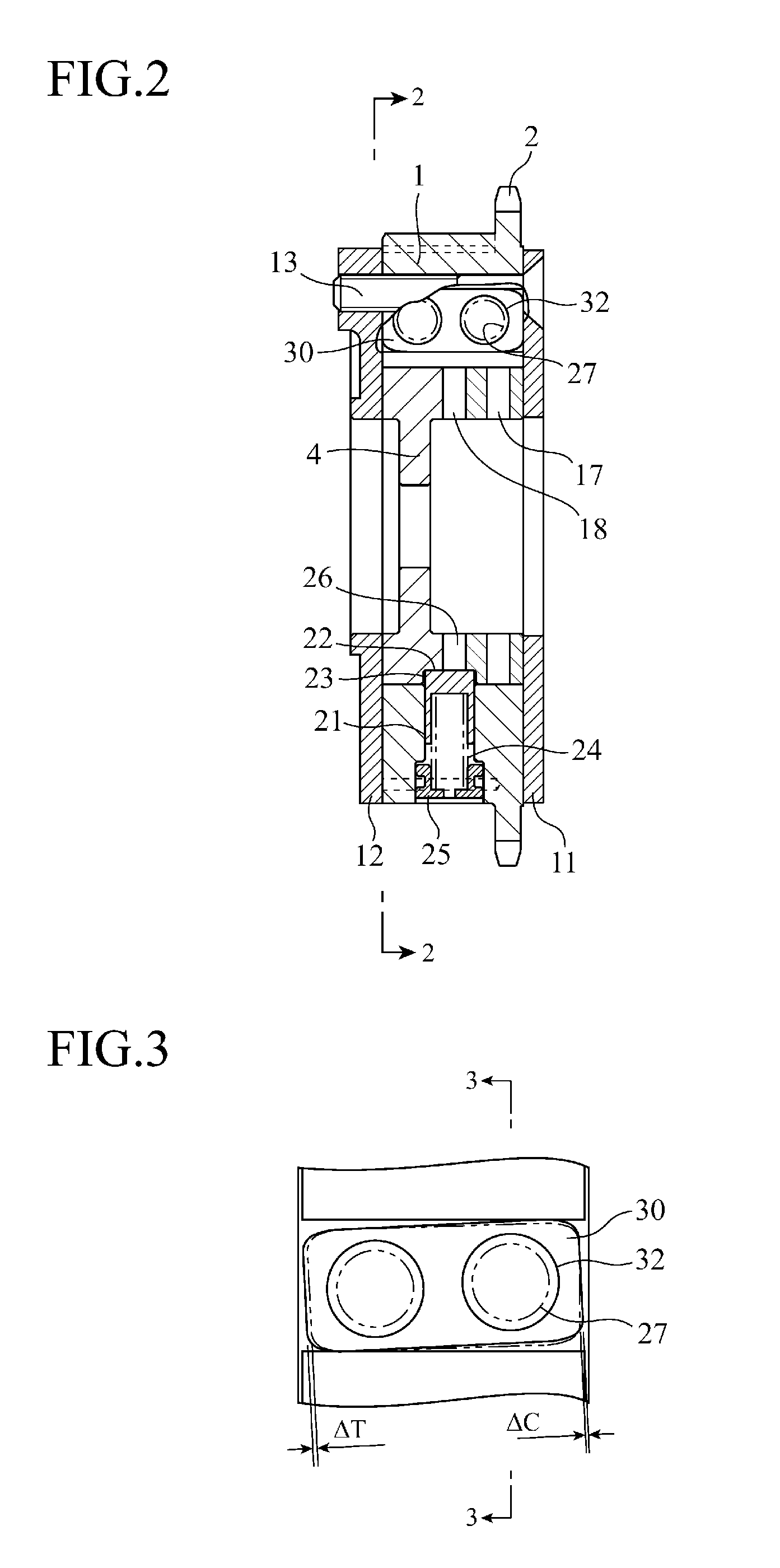

[0014]FIG. 1 is a radial direction sectional view of a valve timing adjusting apparatus of a first embodiment in the present invention, taken along a line 2-2 in FIG. 2, and FIG. 2 is an axial direction sectional view of the valve timing adjusting apparatus of the first embodiment in the invention, taken along a line 1-1 in FIG. 1.

[0015]In the drawings, a sprocket portion 2 for transmitting a driving force from a crank (not shown) is formed on the outer periphery of a case 1, and shoes 3a to 3d forming hydraulic chambers are provided in the inner peripheral portion of the case 1. Vanes 7a to 7d that divide the four hydraulic chambers formed by the shoes 3a to 3d of the case 1 into advance-side hydraulic chambers 5a to 5d and retard-side hydraulic chambers 6a to 6d, and that are also hydraulic pressure reception portions are disposed on the outer side of a rotor 4 at intervals of substantially 90 degrees. In the rotor 4, a boss portion 9 is in sliding contact with an inner sliding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com