Rapid attachment/detachment mechanism for weapon-mountable lighting devices

a technology of lighting devices and attachment mechanisms, which is applied in the direction of sighting devices, cartridge extractors, weapons, etc., can solve the problems of not being able to maintain the position during normal use, commercially available systems' attachment means are not ruggedized, and most systems do not provide for rapid attachment or detachment from the rail system. , to achieve the effect of easing the attachment effort, speeding up the detachment, and being less vulnerable to inadvertent movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

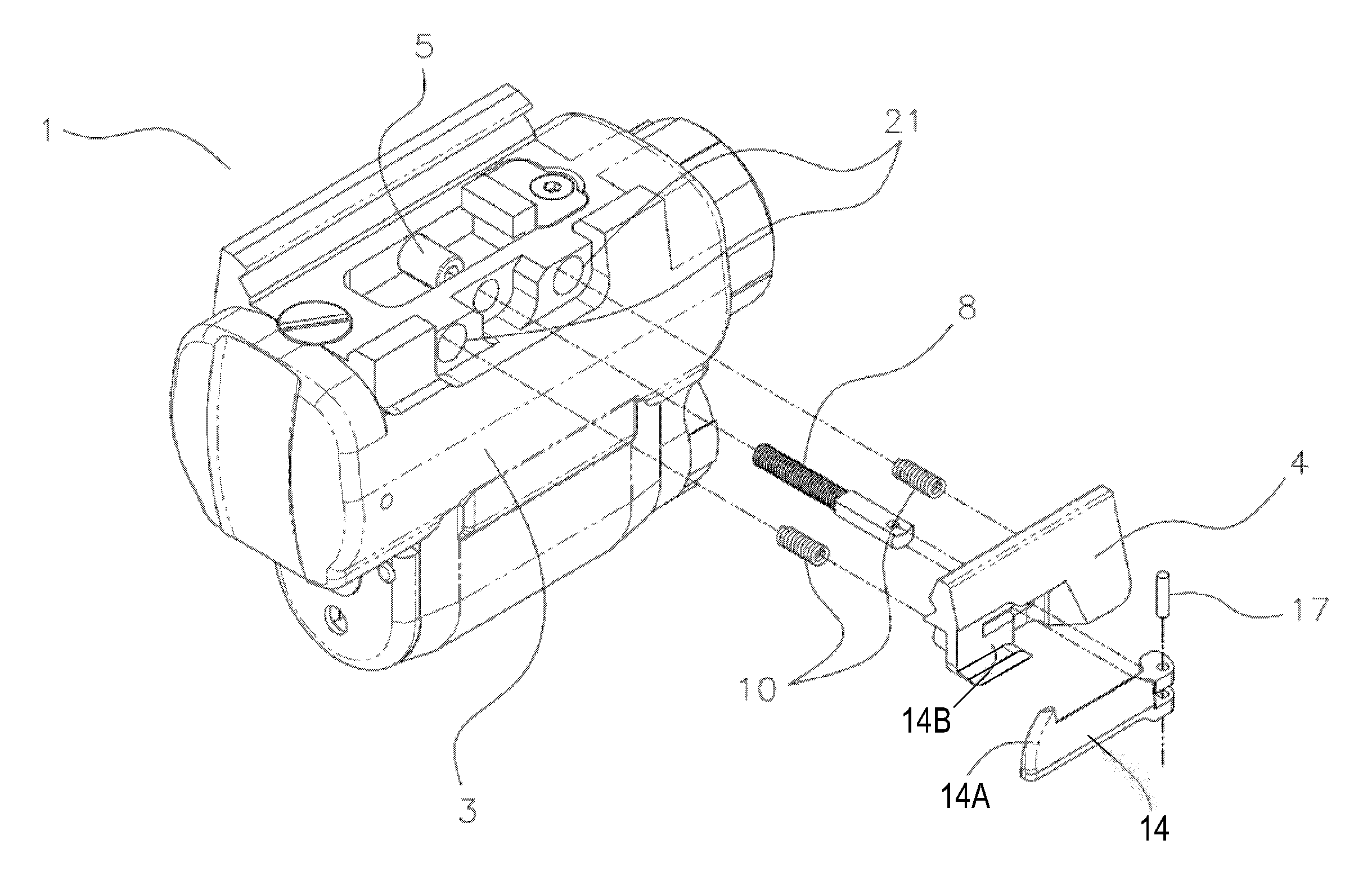

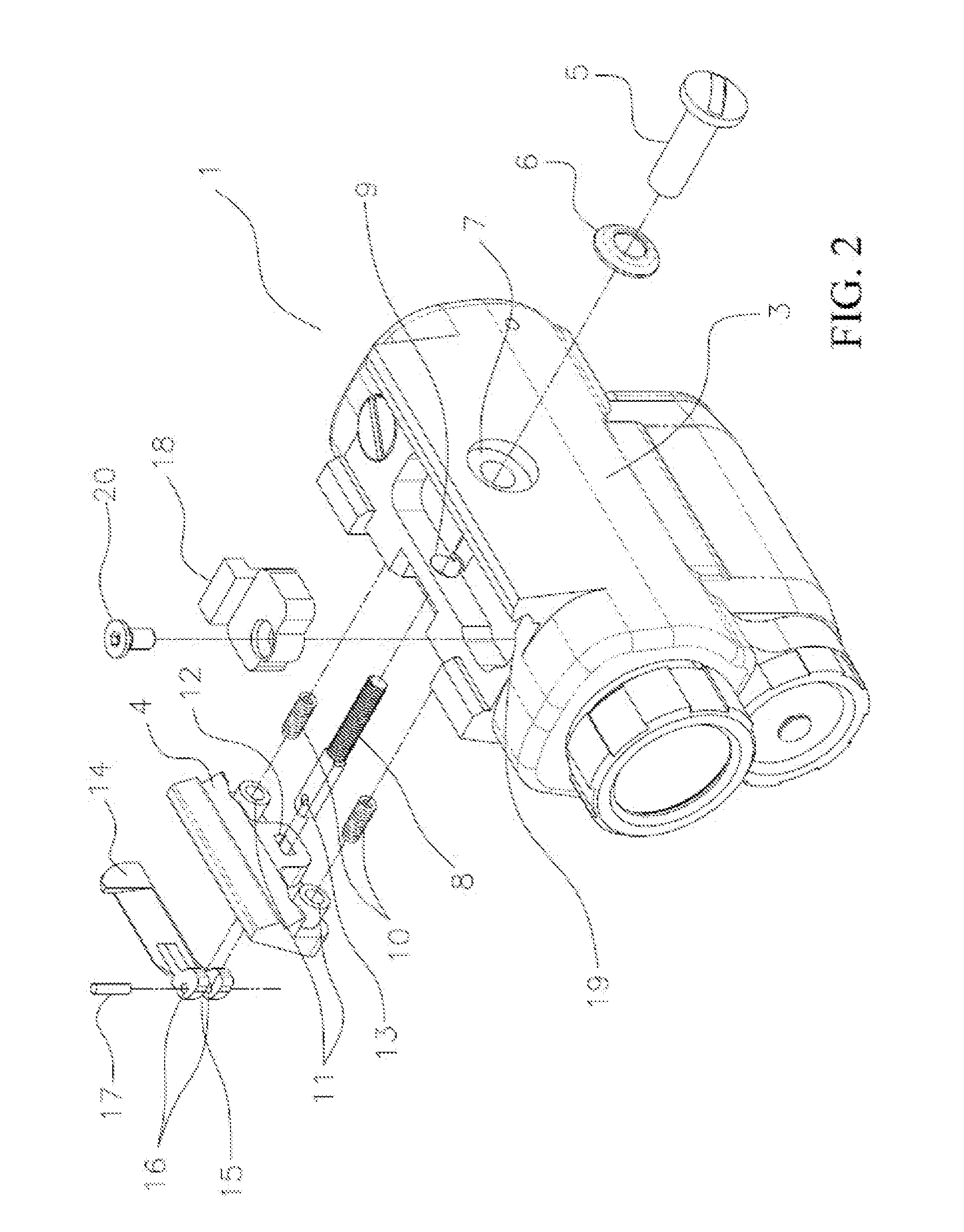

[0022]This invention allows for rapidly attaching or detaching a weapon-mountable lighting device to a weapon rail system, for example, a Picatinny 1913 or similar mounting schemes utilized with host weapon systems. As will be described below, the invention utilizes a cam lever to engage a floating rail clamp to apply pressure to a host weapon rail system. The floating rail is symmetrically biased in an open position to allow for rapid and solid attachment of a weapon-mountable lighting device to the rail of the host weapon, and also allows for quick detachment of the device.

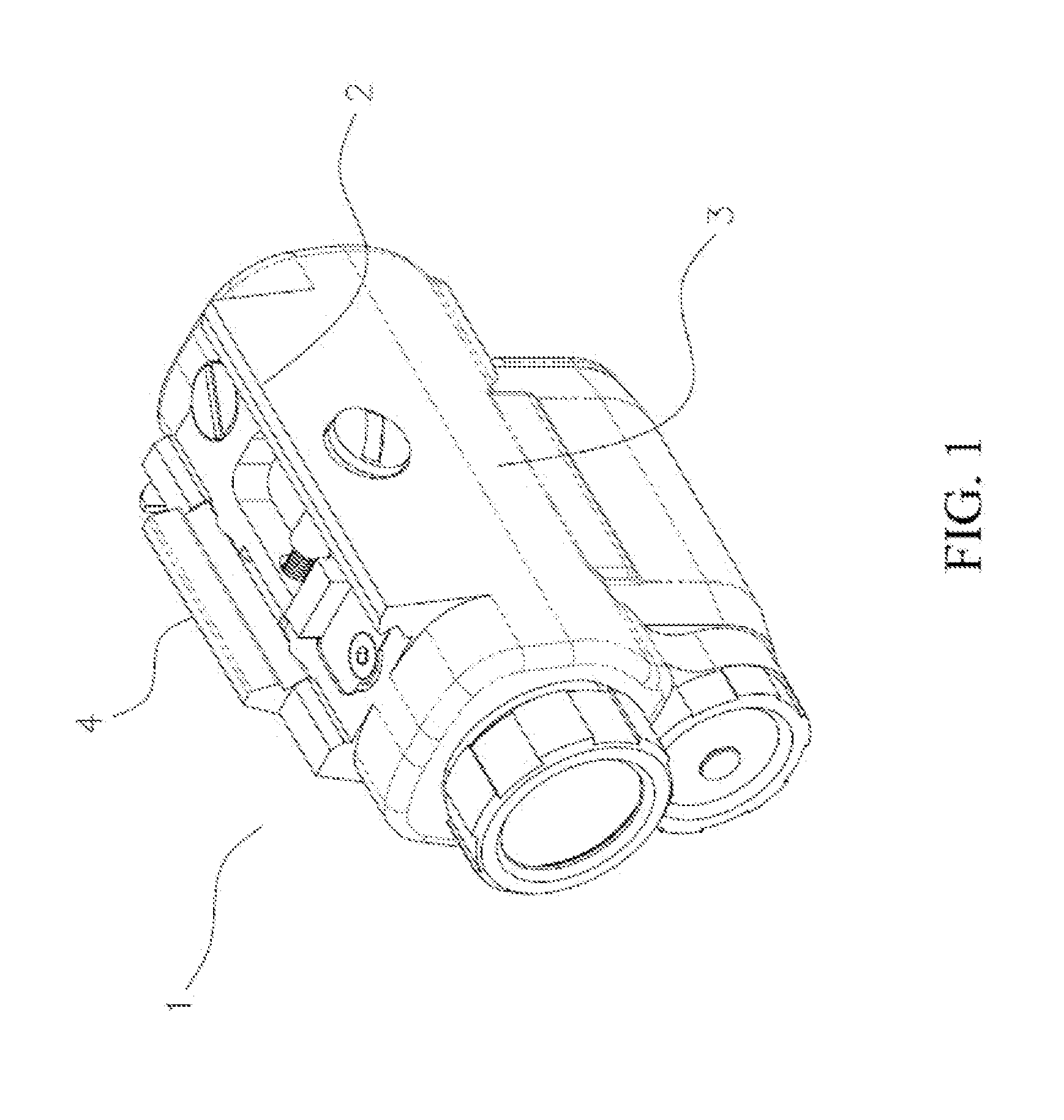

[0023]Referring to FIG. 1, a weapon-mountable lighting device is represented as being equipped with a rapid attachment / detachment mechanism 1 in accordance with an embodiment of the present invention. The lighting device may be, for example, a laser designator / illuminator commercially produced by Laser Genetics of America, LTD. The mechanism 1 comprises a rigid and fixed rail clamp 2 that is either integrated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com