Internal heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

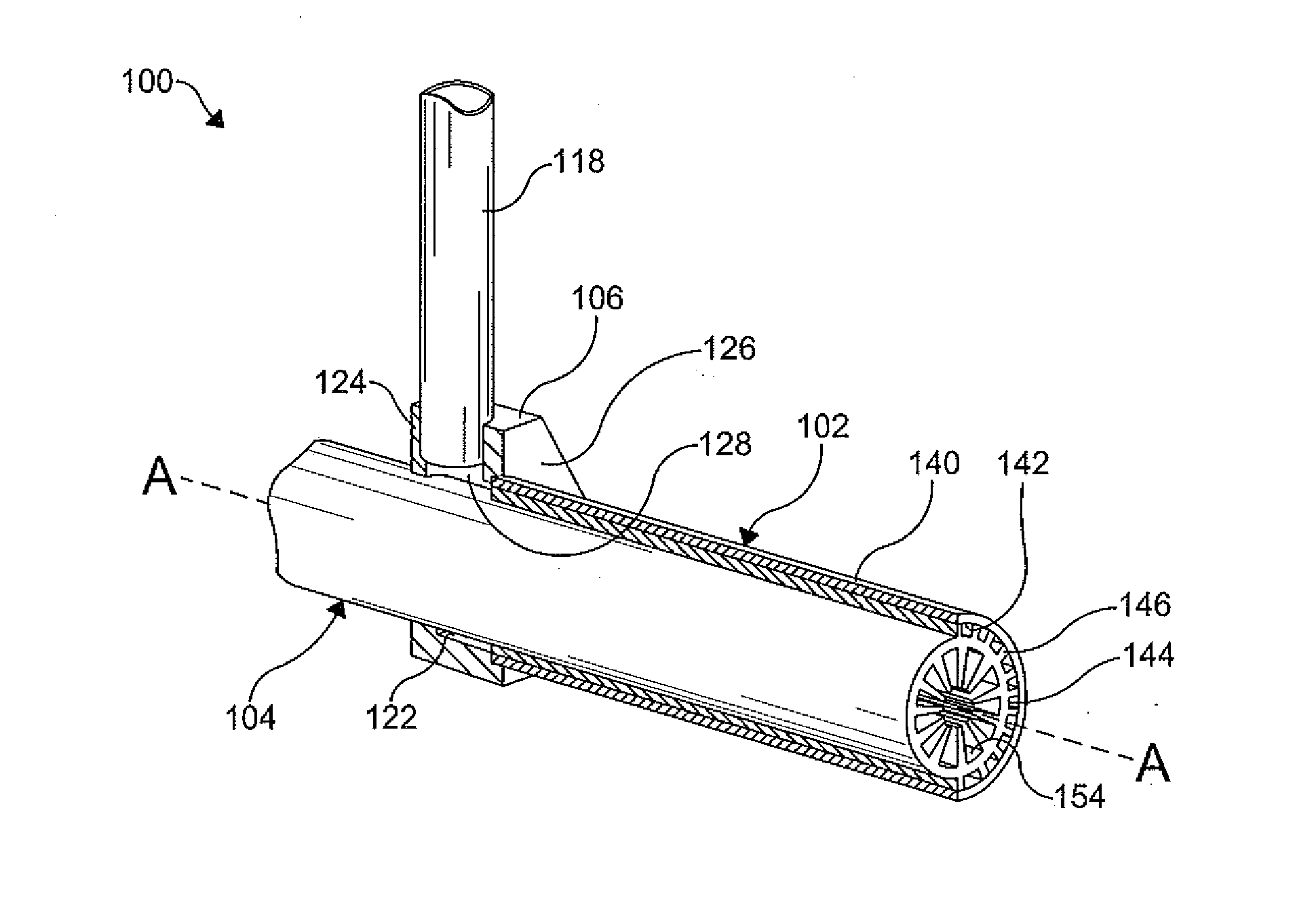

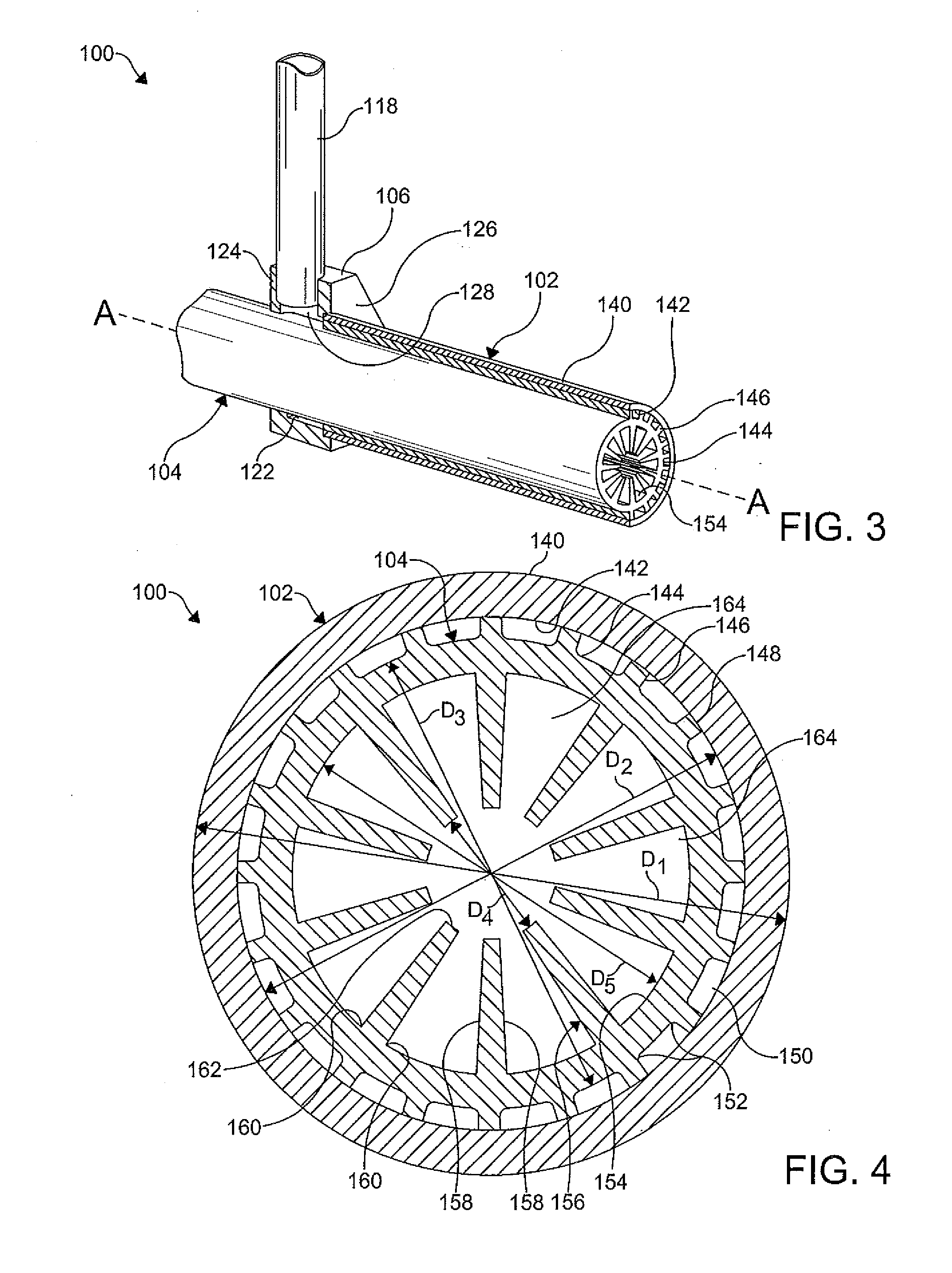

[0023]The following detailed description and appended drawings describe and illustrate an exemplary embodiment of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner.

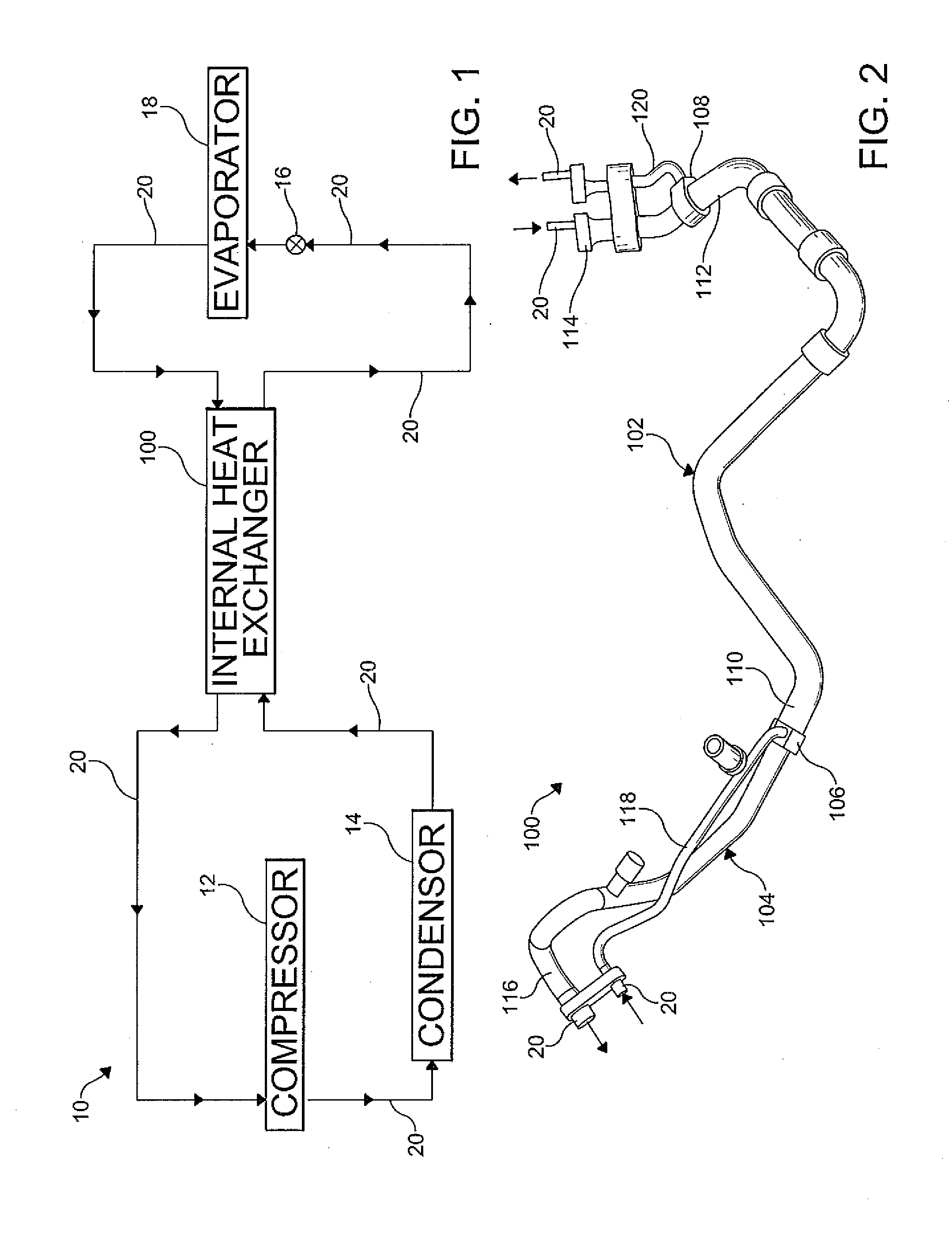

[0024]FIG. 1 is a schematic view of an air conditioning system 10 of a motor vehicle (not shown). The air conditioning system 10 includes a compressor 12, a condenser 14, an expansion device 16, and an evaporator 18 fluidly connected by conduits 20. The air conditioning system 10 further includes a counter flow or internal heat exchanger (IHX) 100 to increase a heat transfer capacity of the air conditioning system 10. It is understood that the IHX 100 is not limited to use in vehicle air conditioning systems 10, and can be employed in other non-automotive applications requiring a heat exchanger. It is further understood that the air conditioning system 10 can include other components neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com