Camera module with tolerance adjustment using embedded active optics

a technology of optical control and camera module, which is applied in the field of optical devices and assemblies, can solve the problems of insufficient optical and physical manufacturing tolerances to ensure the desired precision, and the overall device focusing power is changed, so as to achieve acceptable optical performance and shorten the overall lens design. the effect of the improvemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention is directed to an optical lens apparatus that uses fixed lenses in combination with an electrically controllable liquid crystal optical device. Depending on the specific configuration, the apparatus may be directed to one of several applications. In each of these embodiments, the apparatus uses the optical properties of the fixed lenses in combination with the electrically controlled optical properties of the liquid crystal device.

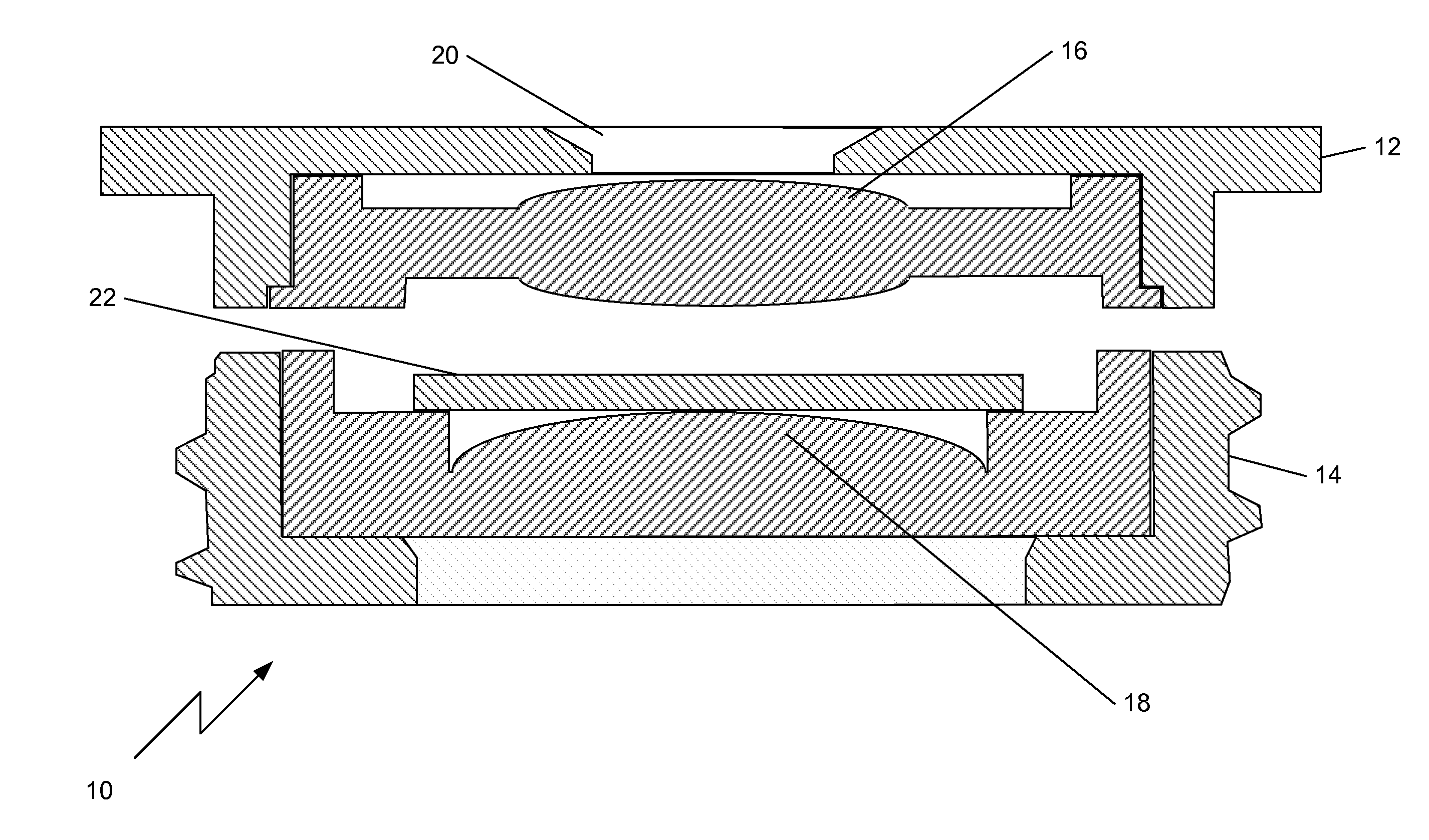

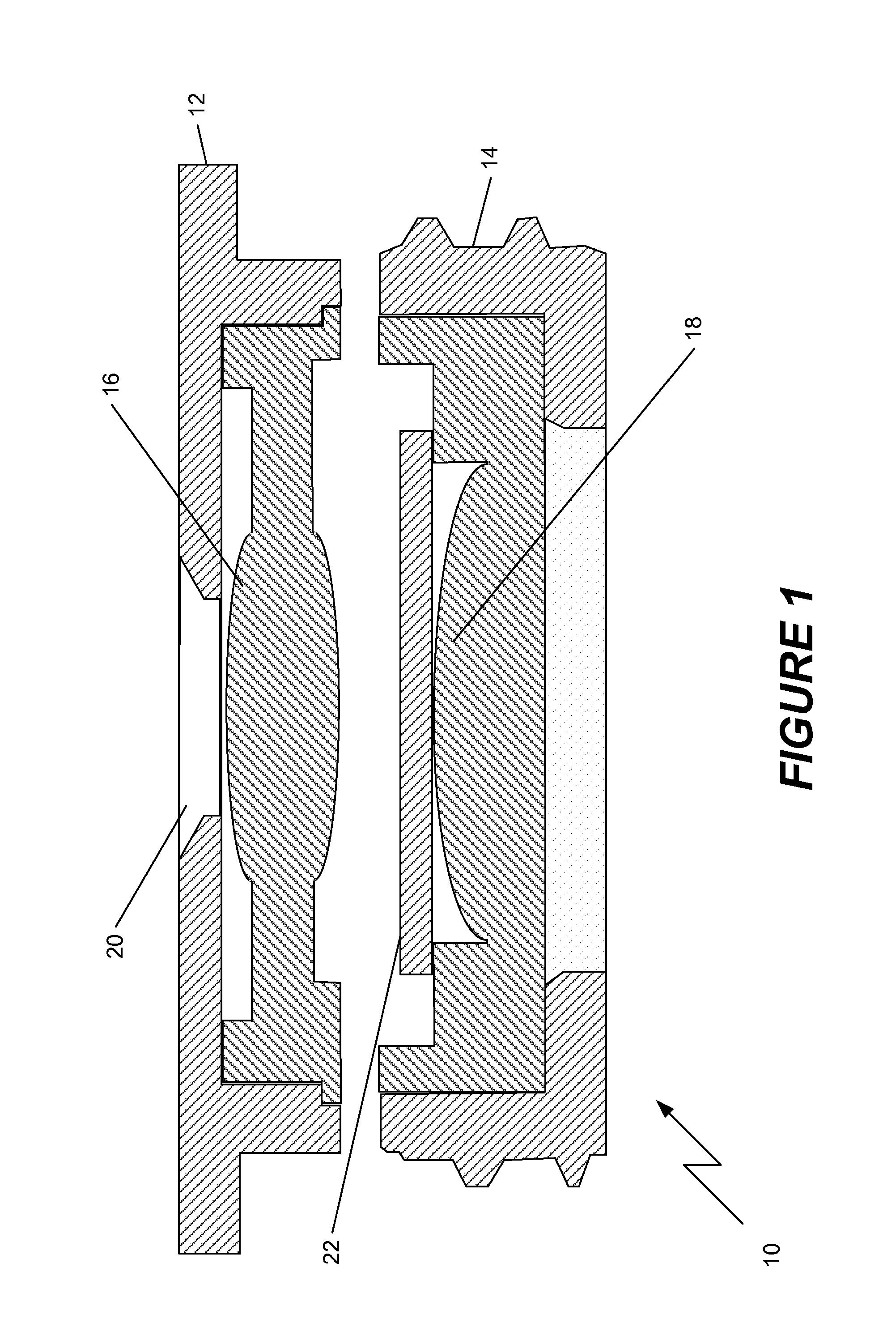

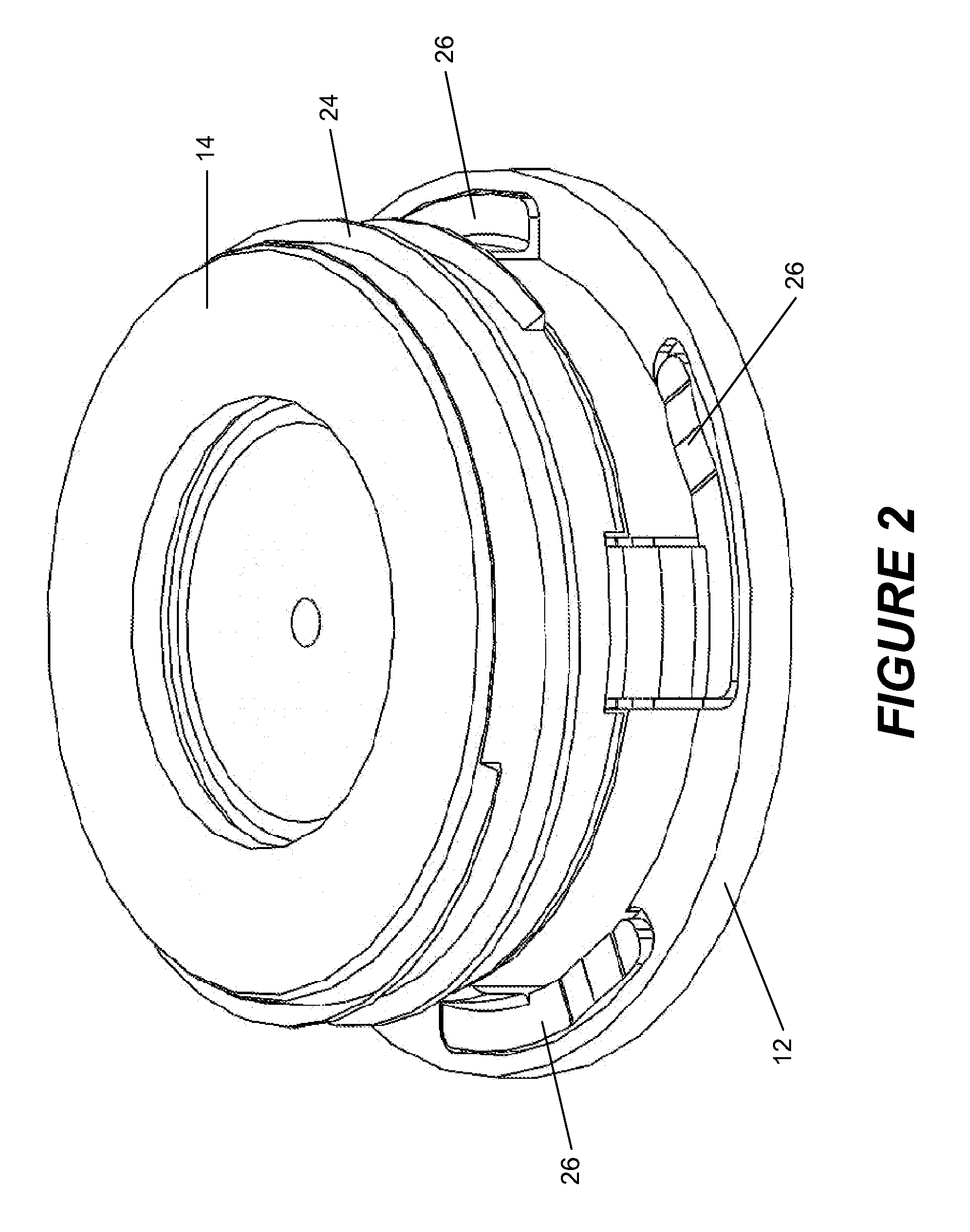

[0036]Shown in FIG. 1 is a schematic view of a first embodiment of the invention in which a variable focus lens 10 has a barrel structure consisting of two portions, an outer portion 12 and an inner portion 14. The lens may be used in a variety of different applications, including compact digital cameras, such as might be integrated into a portable telephone. Each of the two portions includes a fixed lens, lens 16 in the outer portion 12, and lens 18 in the inner portion 14. Each of the lenses in this embodiment are an integral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical power | aaaaa | aaaaa |

| optical power | aaaaa | aaaaa |

| optical characteristics | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com