Electroerosion machining systems and methods

a technology of electroerosion machining and machining system, applied in the direction of manufacturing tools, electrolysis components, electrolysis processes, etc., can solve the problems of disadvantageous subsequent electroerosion machining, the machining quality of the workpiece is affected by heat on the workpiece, and the material properties are undesirabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]Preferred embodiments of the present disclosure will be described hereinbelow with reference to the accompanying drawings. In the following description, well-known functions or constructions are not described in detail to avoid obscuring the disclosure in unnecessary detail.

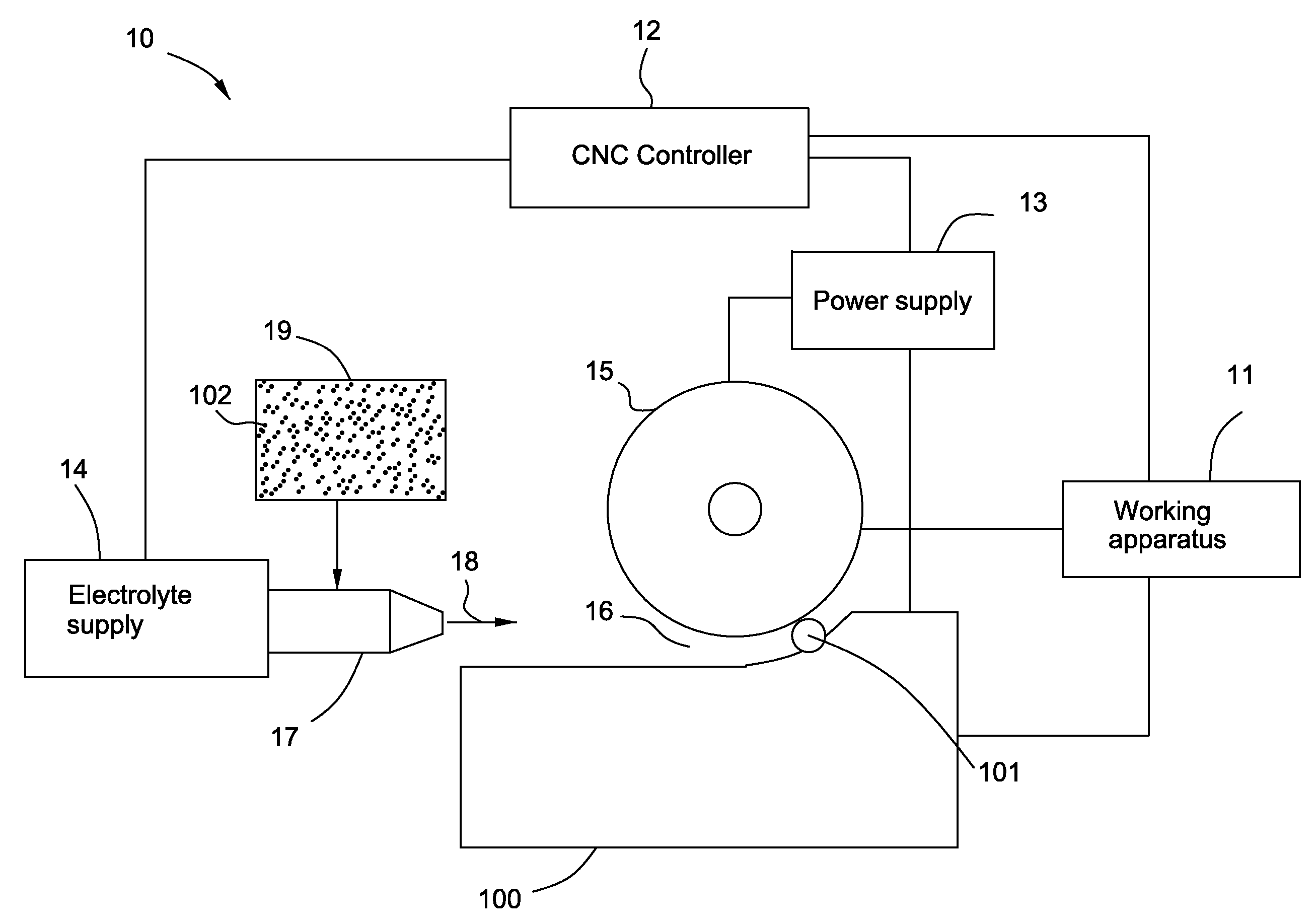

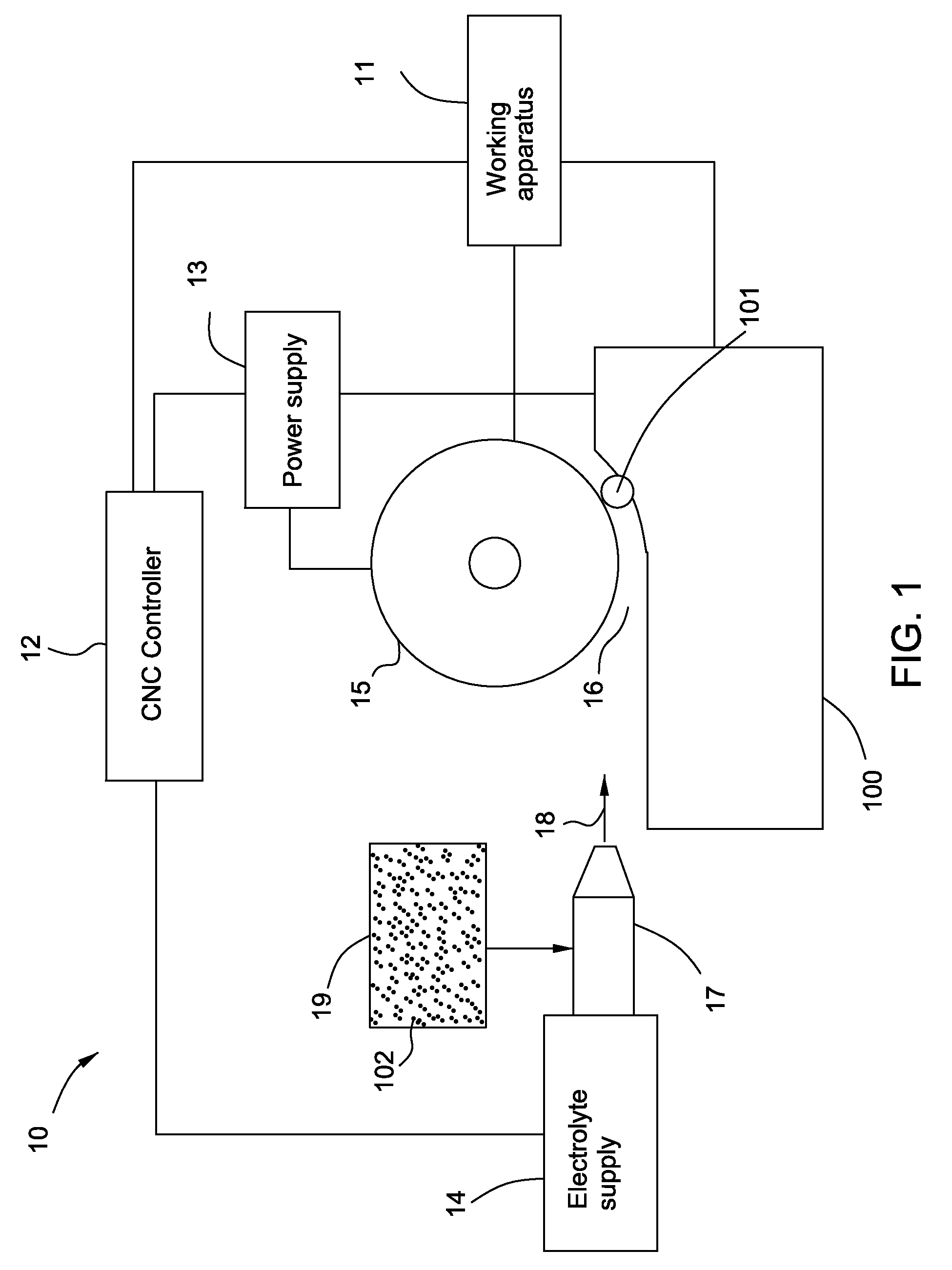

[0013]FIG. 1 illustrates a schematic diagram of an electroerosion machining system 10 in accordance with one embodiment of the invention. In embodiment of the invention, the electroerosion machining system 10 is used to remove material from a workpiece 100, such as titanium alloy layer by layer to form a desired configuration. As illustrated in FIG. 1, the electroerosion machining system 1 comprises a numerical control (NC) or computer numerical control (CNC) device (not shown) including a working apparatus 11 and a controller 12, a power supply 13, an electrolyte supply 14, and an electrode 15. In one non-limiting example, the electroerosion machining system 1 comprises a high speed electroerosion (HSEE) m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com