Synthetic Resin Bearing For Photovoltaic Tracking System

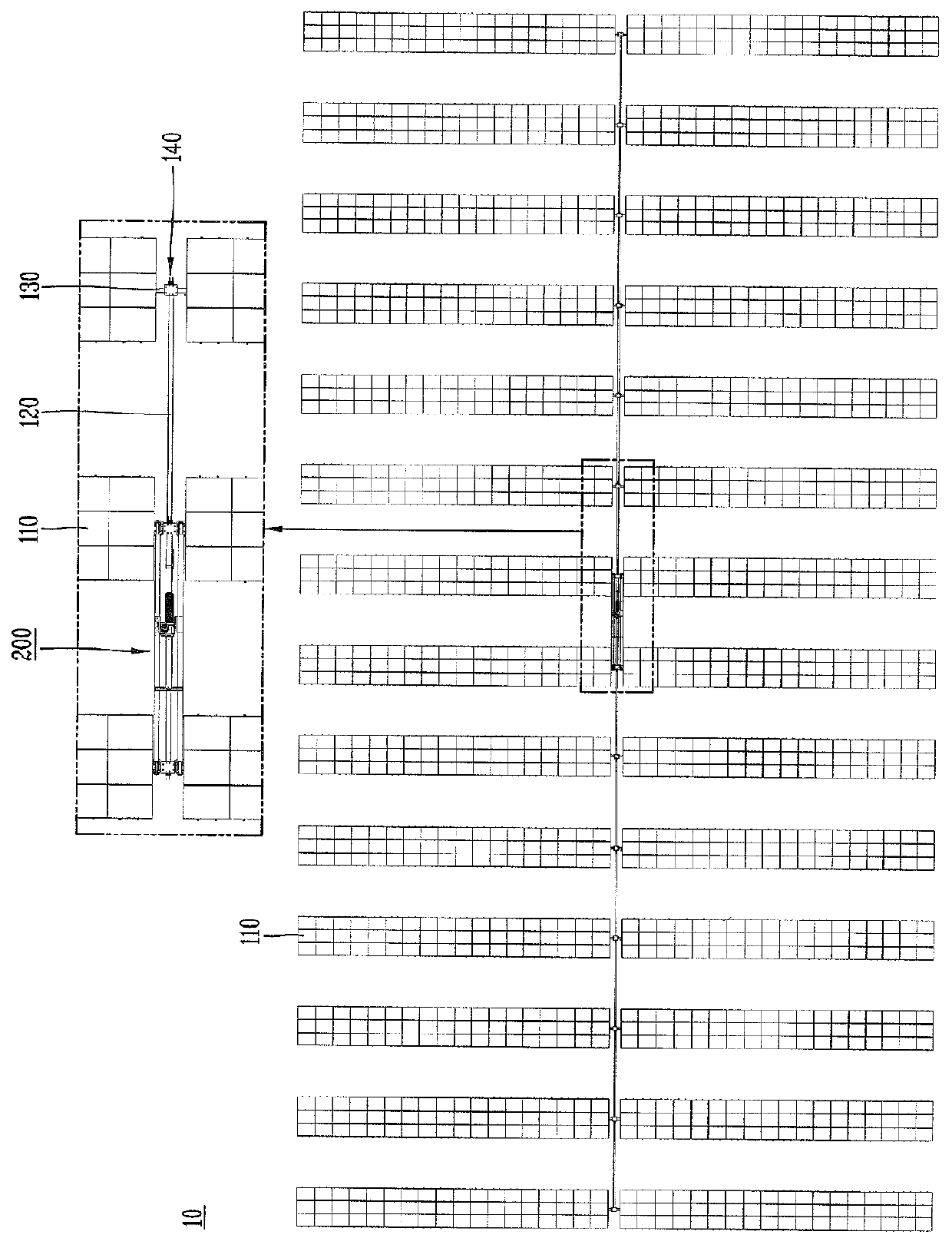

a technology of photovoltaic tracking and synthetic resin, which is applied in the direction of bearing unit rigid support, heat collector mounting/support, light and heating apparatus, etc., can solve the problems of increasing difficulty of work, inconvenient addition of lubricant, and increasing difficulty of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Challenges

[0007]The present invention is devised to overcome the above mentioned traditional disadvantages, and to provide synthetic resin bearing assembly for a photovoltaic tracking system to keep proper friction coefficient without the necessity of applying a lubricant.

TECHNICAL SOLUTION

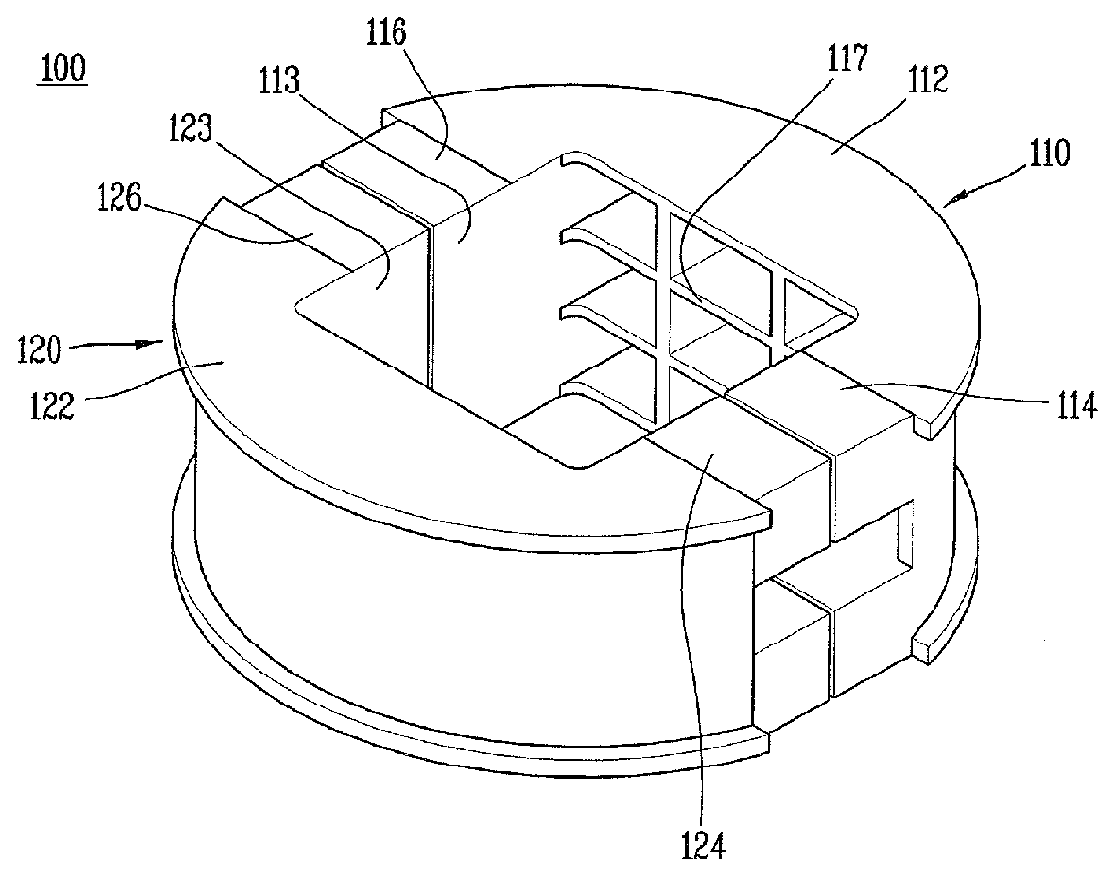

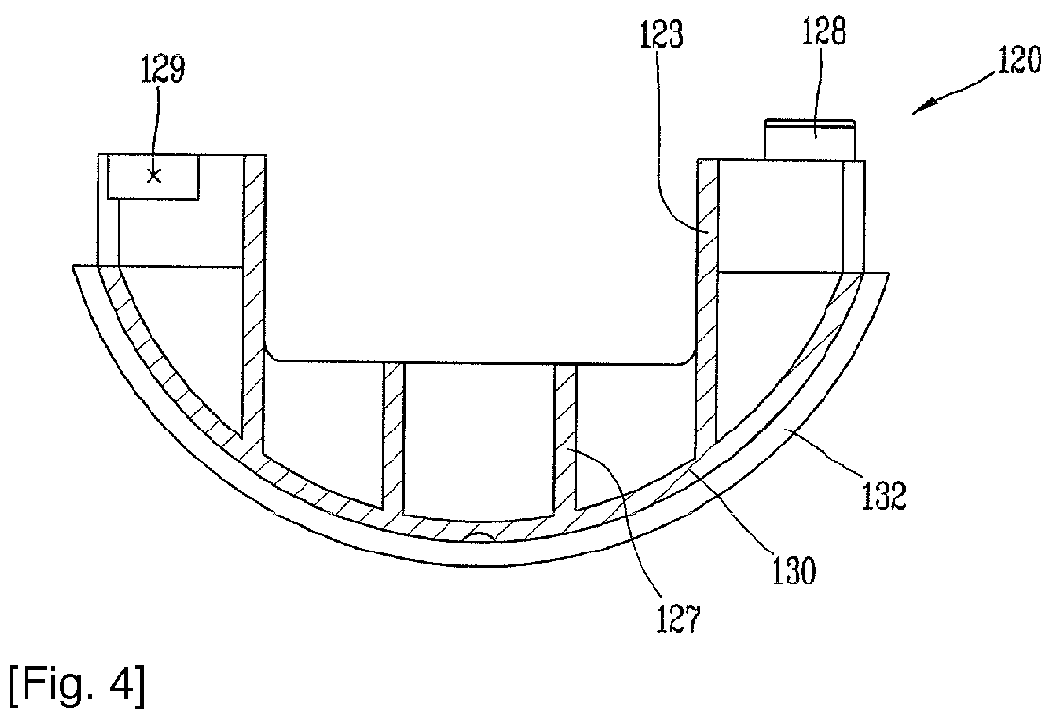

[0008]In order to achieve said technical challenges, the present invention is a synthetic resin bearing for a photovoltaic tracking system including the first and second bearing members coupled with each other for forming a bearing assembly, wherein each of the first and second bearing members comprises of a pair of side plate members facing each other; a friction member positioned between the outer peripheral portions of the pair of side plates and having an arc shaped section; and a reinforcement member for connecting the pair of side plates and the friction member, and the first and second bearing members have a coupling protrusion and a concave portion for receiving the coupling prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com