Compression garments and method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

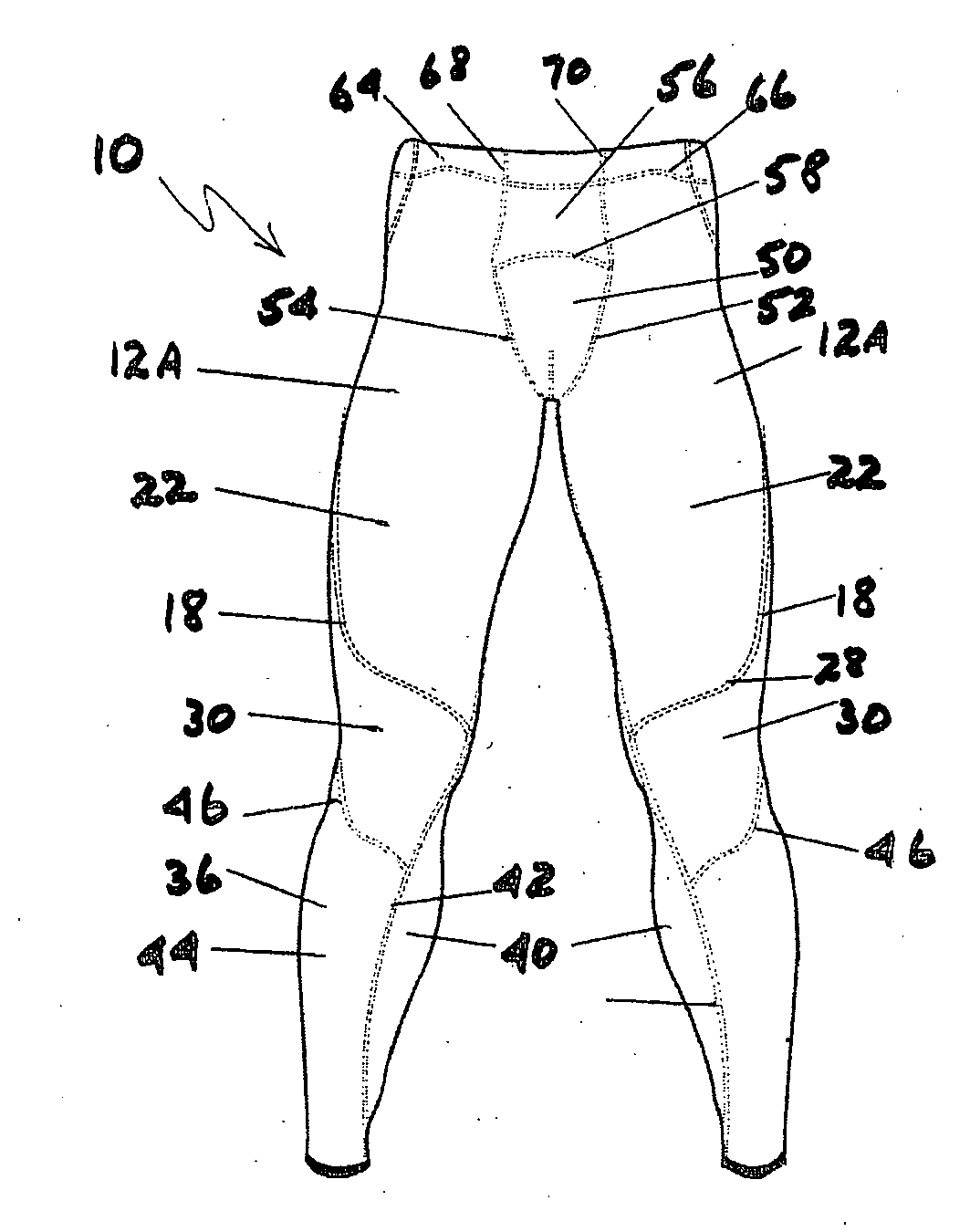

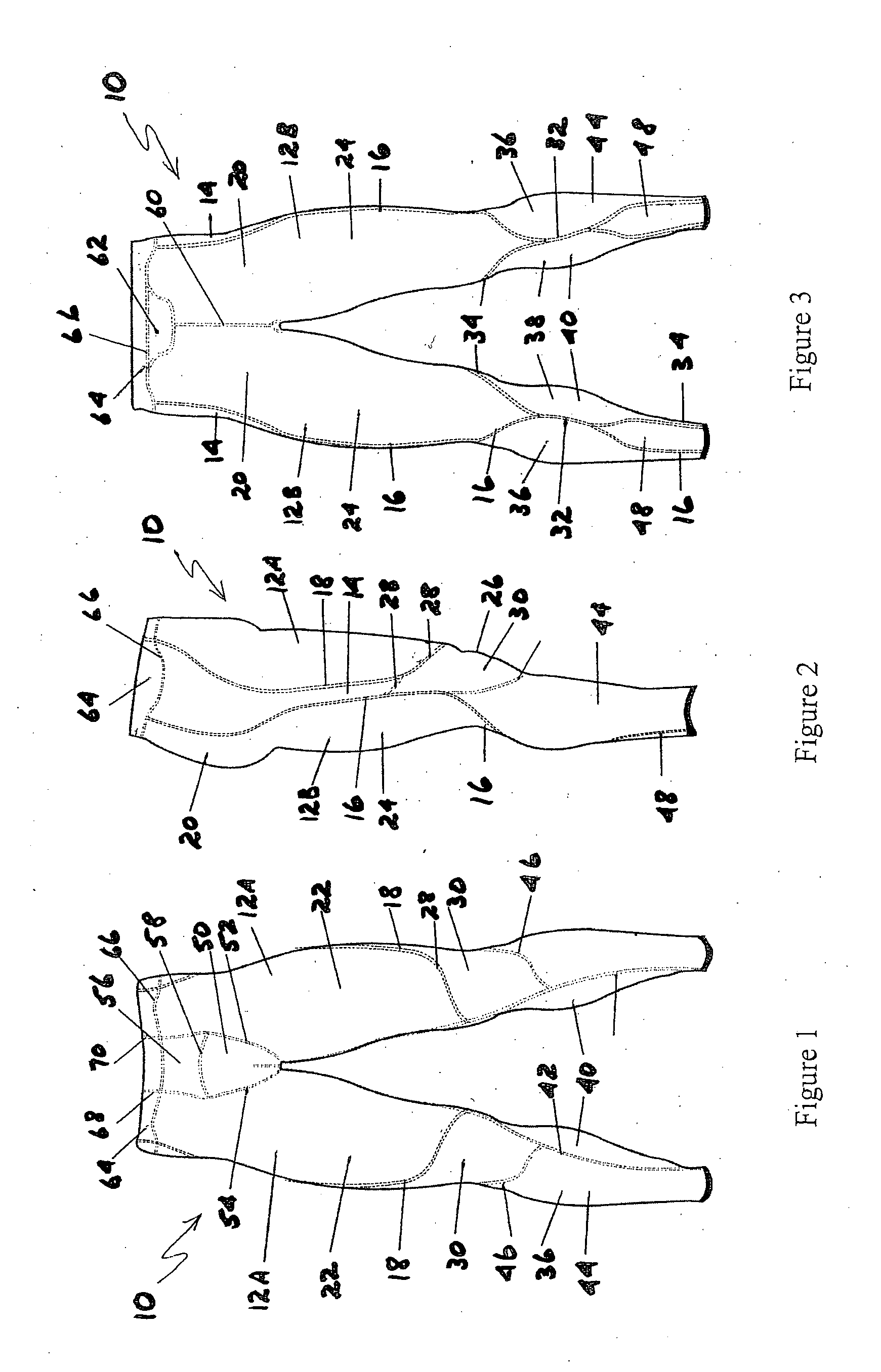

[0048]Referring first to FIGS. 1 to 3, compression garment 10 is shown as a lower body garment in the form of long tights, for clothing a body part being the lower torso, from approximately the wearer's waistline to the wearer's ankles.

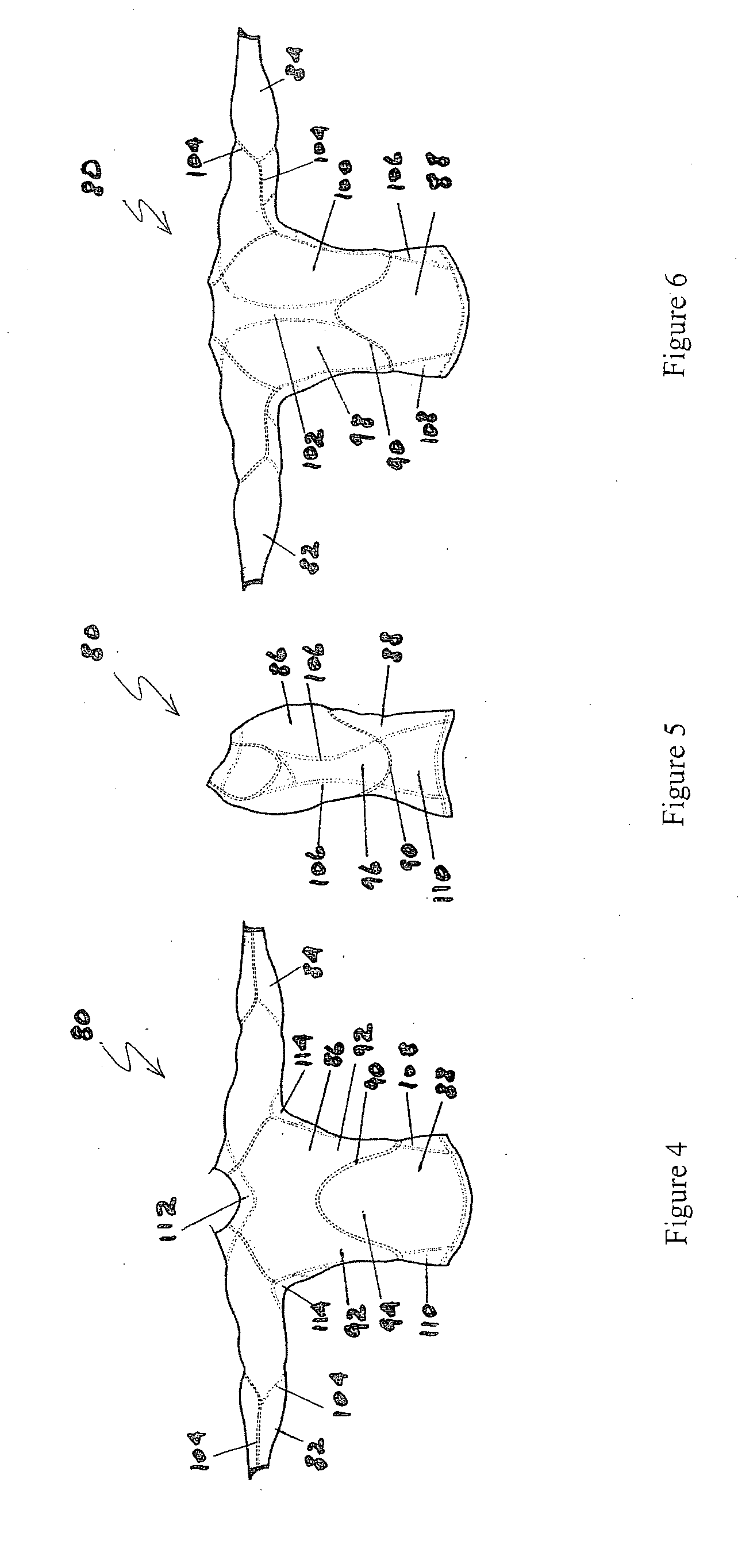

[0049]Long tights 10 have first panels of stretchable material 12A and 12B and a second panel of stretchable material 14. First panel 12A is joined to second panel 14 by second seam 18 First panel 12B is joined to second panel 14 by first seam 16. Effectively, first panel 12 is divided into two parts, 12A and 12B, panel 12A covering the front of the wearer's thigh as shown in FIG. 1 and panel 12B covering the back of the wearer's thigh as shown in FIG. 3, with a seam (not shown) joining the panels 12A and 12B running along the inside thigh of the wearer.)

[0050]First panels 12A and 12B require more force to stretch and therefore are less elastic than second panel 14.

[0051]First panel 12B is adapted to support the gluteus maximus of the wearer, located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com