Method of phasing threaded grinding stone, as well as gear grinding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

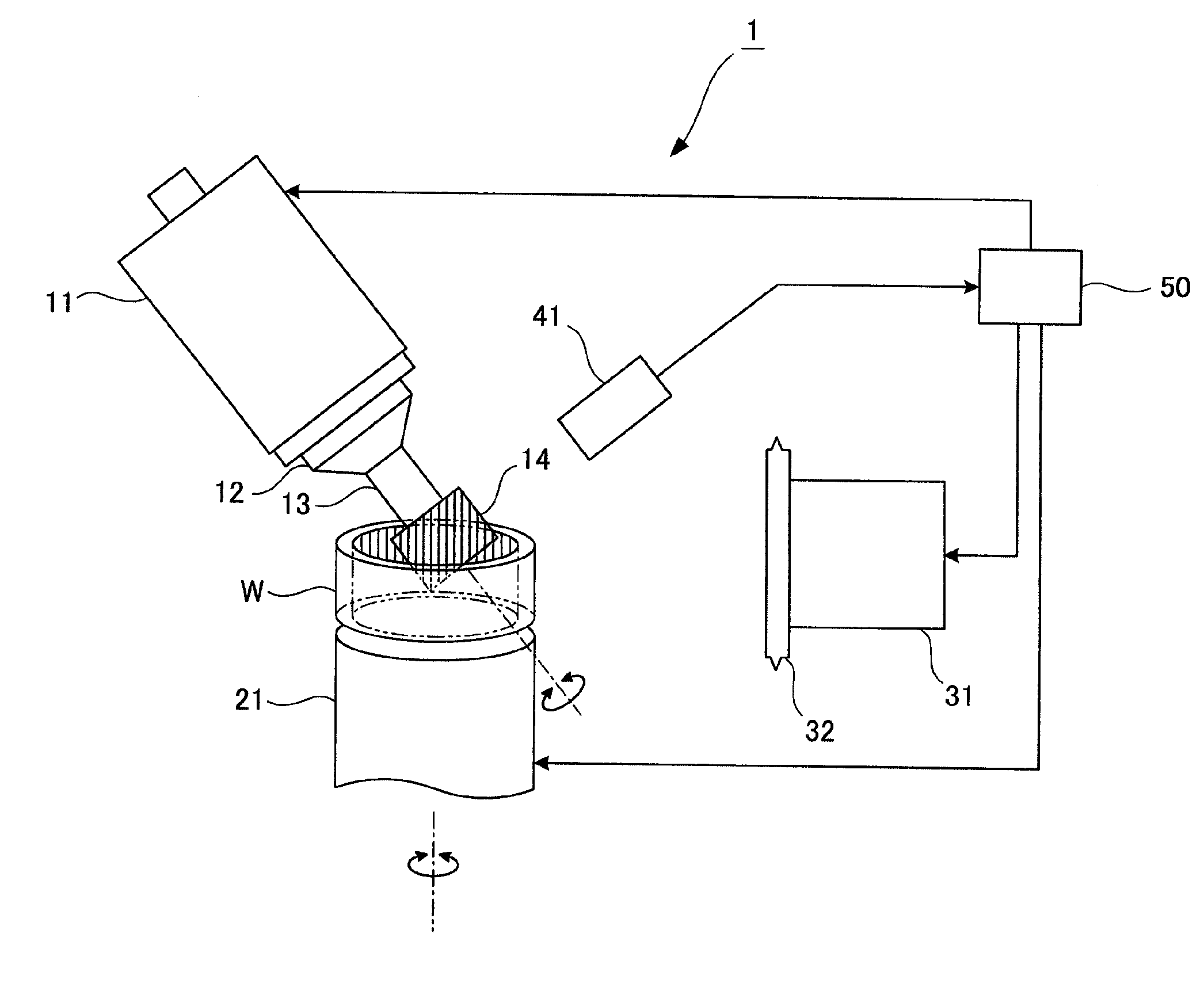

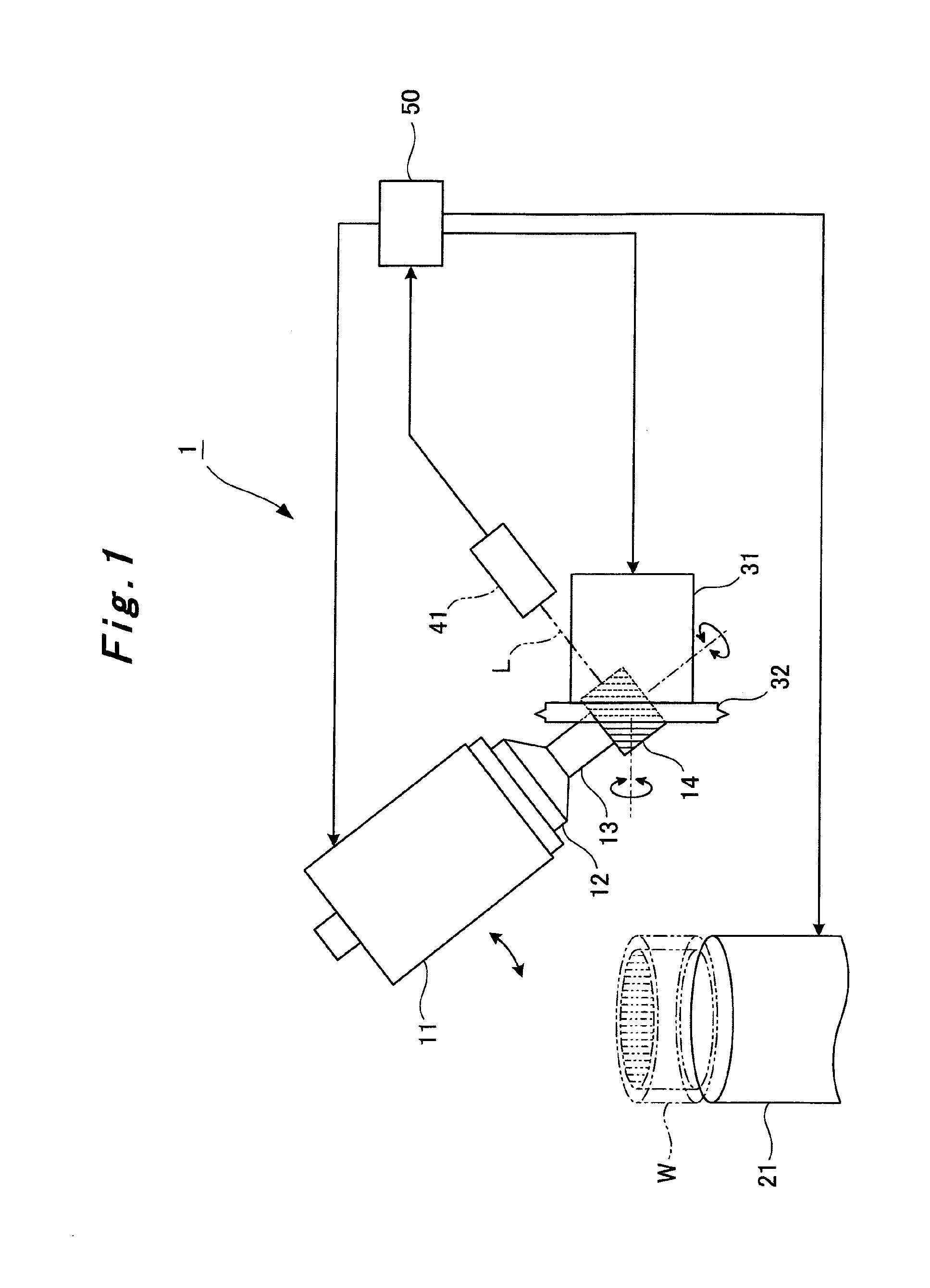

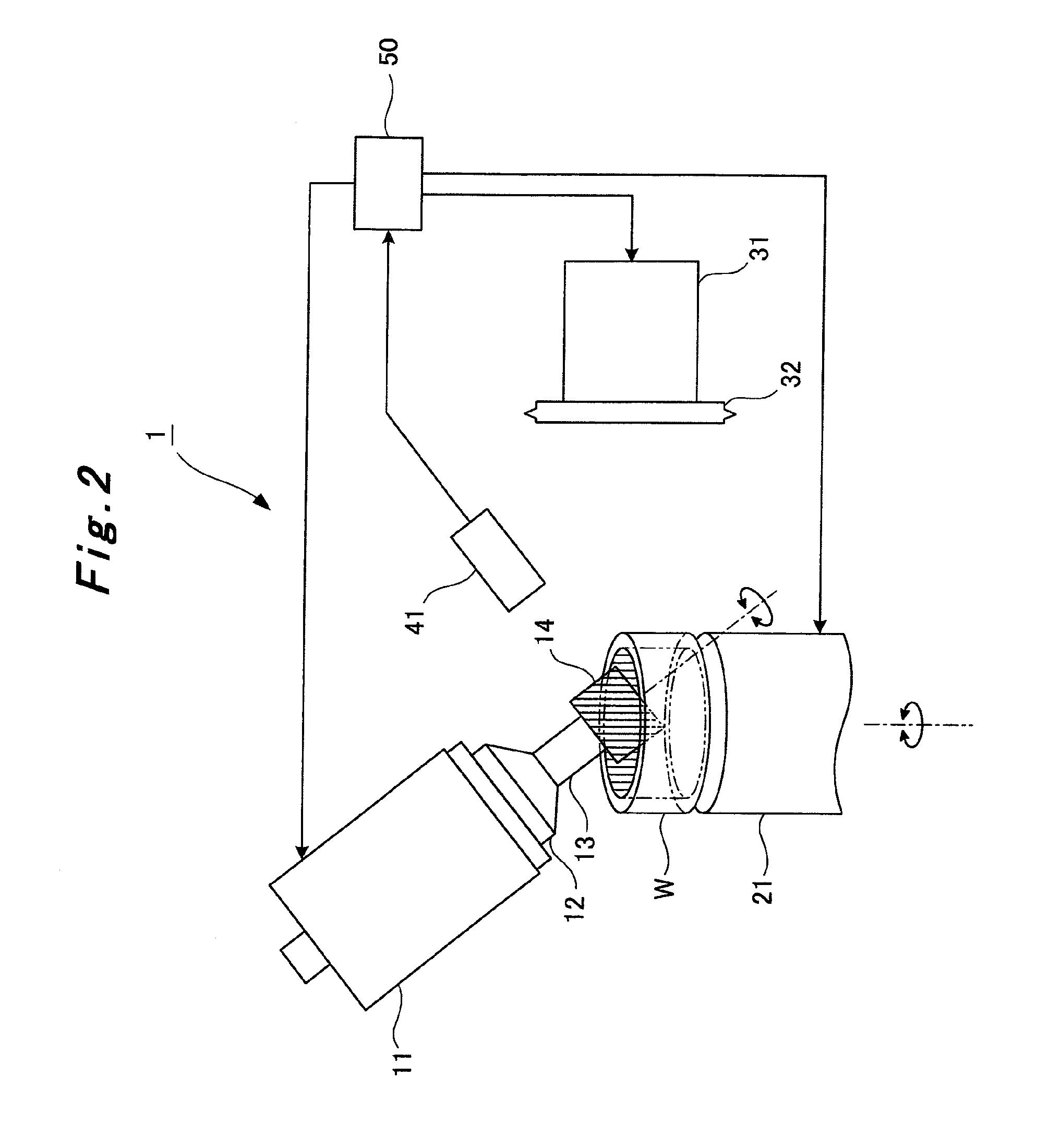

[0040]A gear grinding machine 1 to which the method of phasing a threaded grinding wheel according to the present invention is applied is used to grind a workpiece (gear to be machined) W as a material of an internal gear with a barrel-shaped threaded grinding wheel 14 as shown in FIG. 2. Further, the gear grinding machine 1 has the dressing function of dressing the threaded grinding wheel 14 with a disc dresser 32 as shown in FIG. 1.

[0041]As shown in FIGS. 1 and 2, a grinding wheel head 11 is movably and turnably supported in the gear grinding machine 1. A spindle 12 is rotatably supported by this grinding wheel head 11. At the tip of this spindle 12, a grinding wheel arbor 13 is formed. Further, to the tip of the grinding wheel arbor 13, the threaded grinding wheel 14 is removably attached. Thus, driving the grinding wheel head 11 causes the threaded grinding wheel 14 to be rotationally driven through the grinding wheel arbor 13 of the spindle 12.

[0042]In front of the grinding whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com