Method and apparatus for improving start-up for an air separation apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

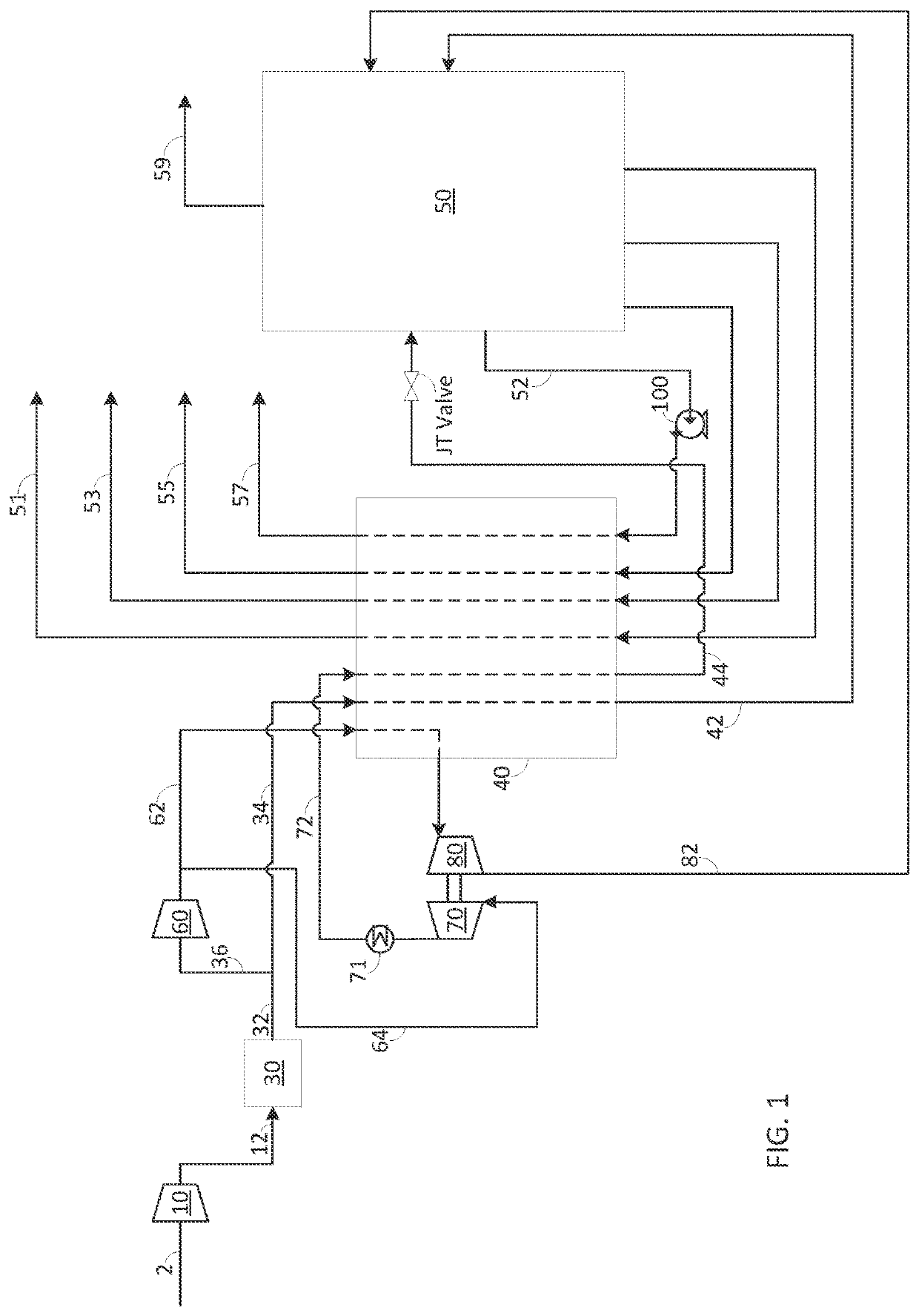

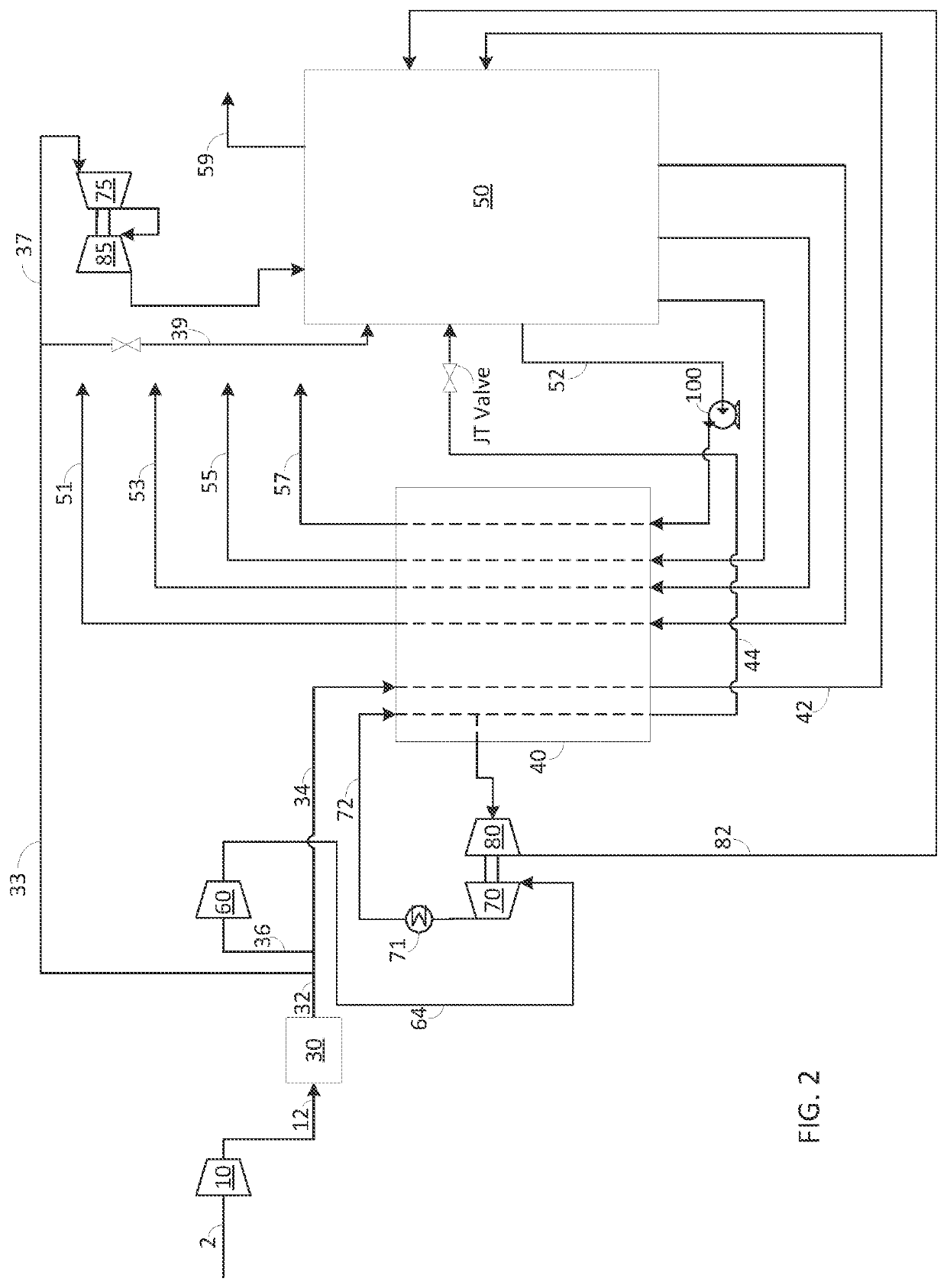

[0020]FIG. 1 provides a schematic representation of an embodiment of the present invention outlining how an ASU can operate in both its steady state operational mode, as well as its cooling down (start-up) mode.

[0021]An air stream 2 is first compressed in a main air compressor 10 and purified of carbon dioxide and water in a front-end purification unit 30. The purified and compressed air 32 is then split into two streams, with one stream 36 being further compressed in a second air compressor 60, while the second stream 34, which is at 6 bara in this example, is sent to the cold box and cooled in a heat exchanger 40, before being sent to the system of distillation columns 50 as stream 42.

[0022]The further compressed air stream 36 can then be further split into a first fraction 62 and a second fraction 64. The first fraction 62, which is at 45 bara in this example, is sent to the cold box and partially cooled in a higher pressure heat exchanger, before being expanded in a turbine 80 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com