Pump device for a container for liquid, pasty or foamable cleansing and skin care preparations

a technology of foaming and scalding lips, which is applied in the direction of single-unit apparatus, domestic applications, positive displacement liquid engines, etc., can solve the problems of film hinge damage, and achieve the effect of facilitating the swiveling of sealing lips and high pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

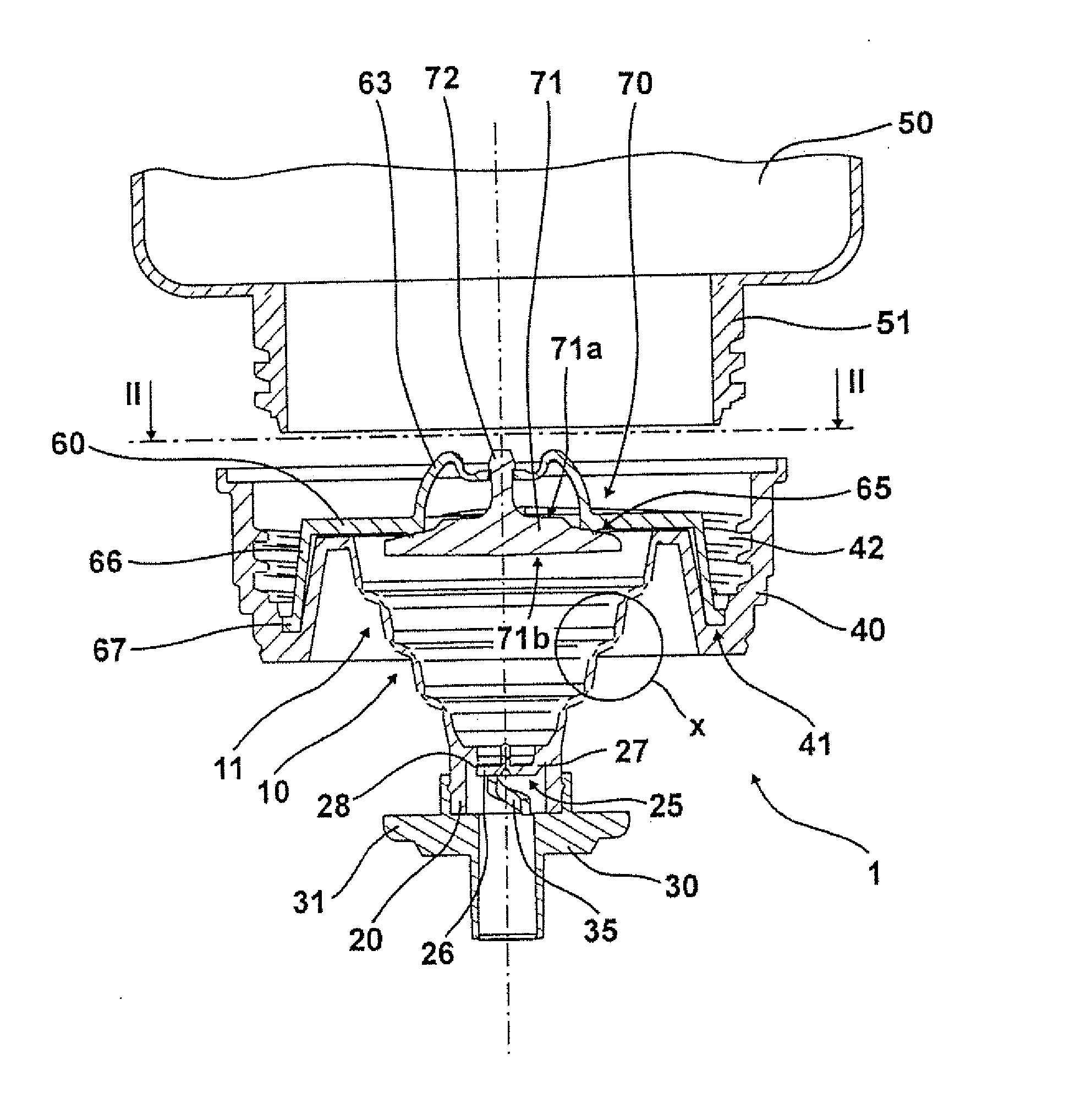

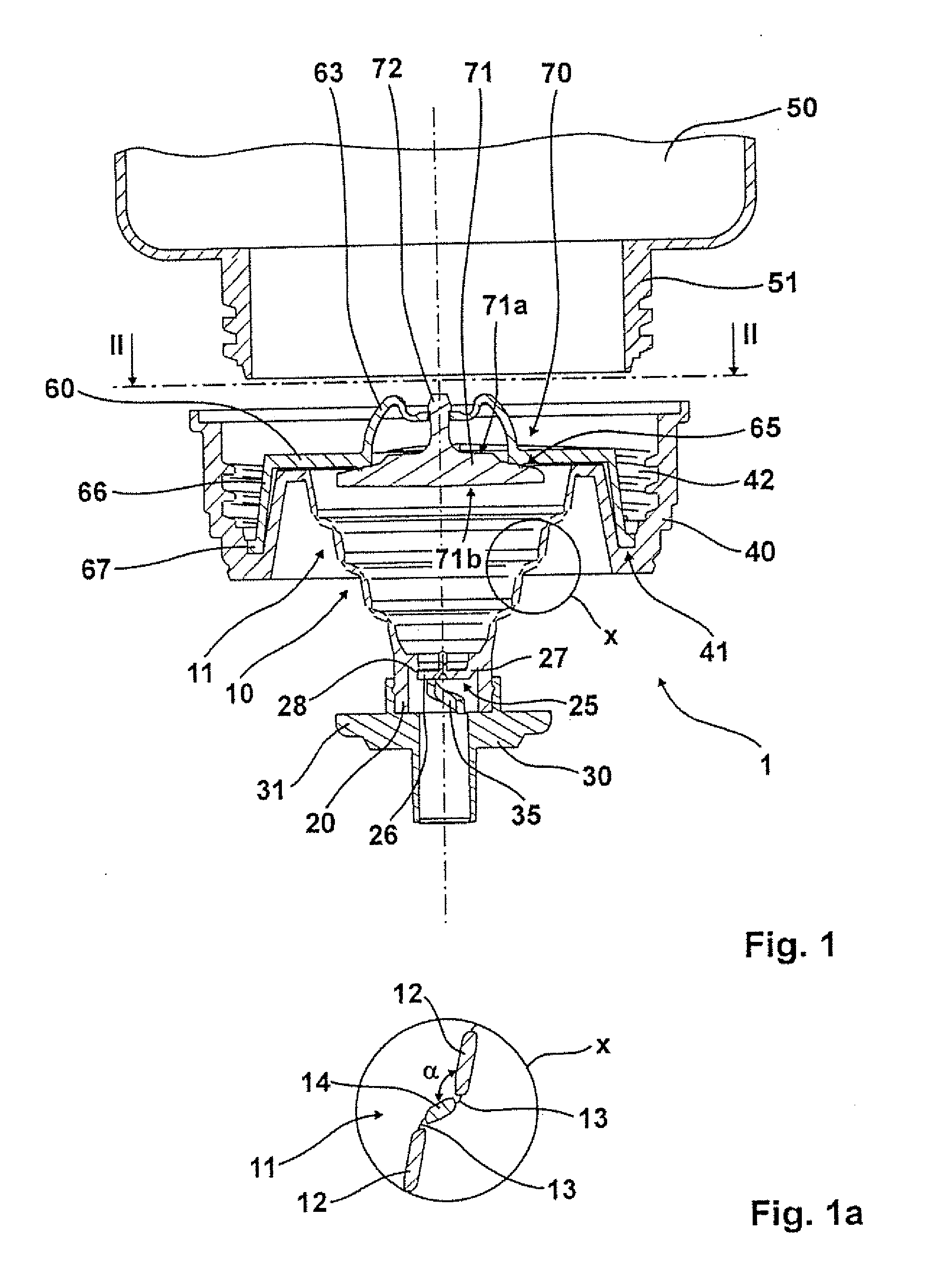

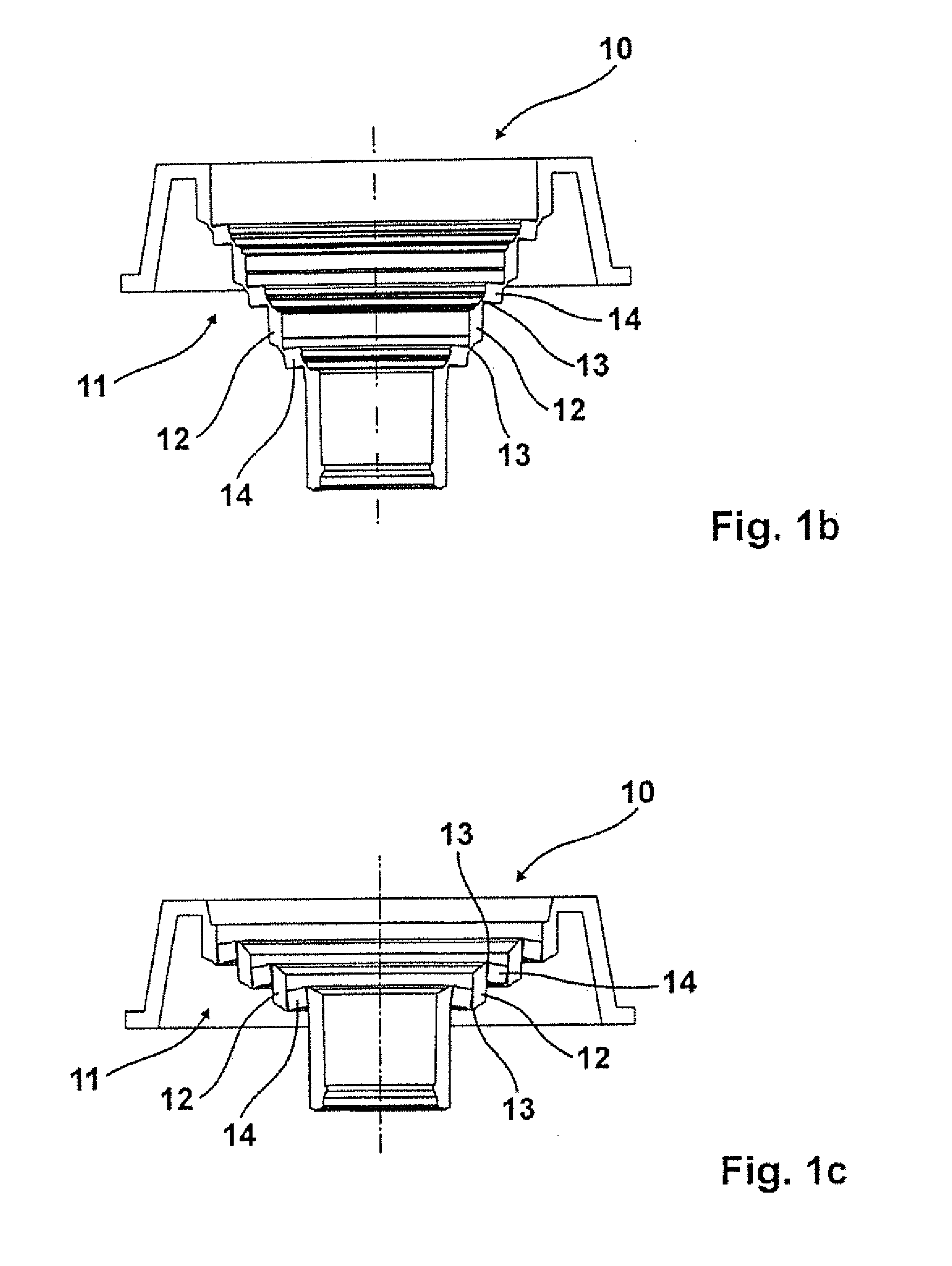

[0035]Taken as a whole the pump device exhibits the reference number 1. The pump device 1 comprises the bellows labeled 10, wherein the bellows has the outlet connector 20 on the outlet side end. The outlet connector 20, which is cylindrical in design, receives the outlet spout labeled 30. The outlet connector 20 shows the outlet valve marked 25, wherein the outlet valve 25 comprises a valve disk 26, which is connected by a web 27 to the outlet connector 20. The outlet spout 30 comprises a protrusion 31 running perpendicular to the longitudinal axis of the pump device, wherein the protrusion 31 can be held by the previously described “catcher clamp”. The outlet spout 30 in addition shows the spring element 35 constructed as a spiral spring, said spring element pressing from below, that is against the direction of the outlet against the valve disk 26, and hence presses the valve disk against the valve seat 28.

[0036]The bellows 10, which forms the bellows chamber 10a, possesses on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com