Modular building system and method

a building system and modular technology, applied in the field of modular building systems and methods, can solve the problems of limiting the access to installed equipment, the size of a standard shipping container, and the complexity of the power plant and computer room of the building, and achieve the effect of preventing the deformation of the modular building uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

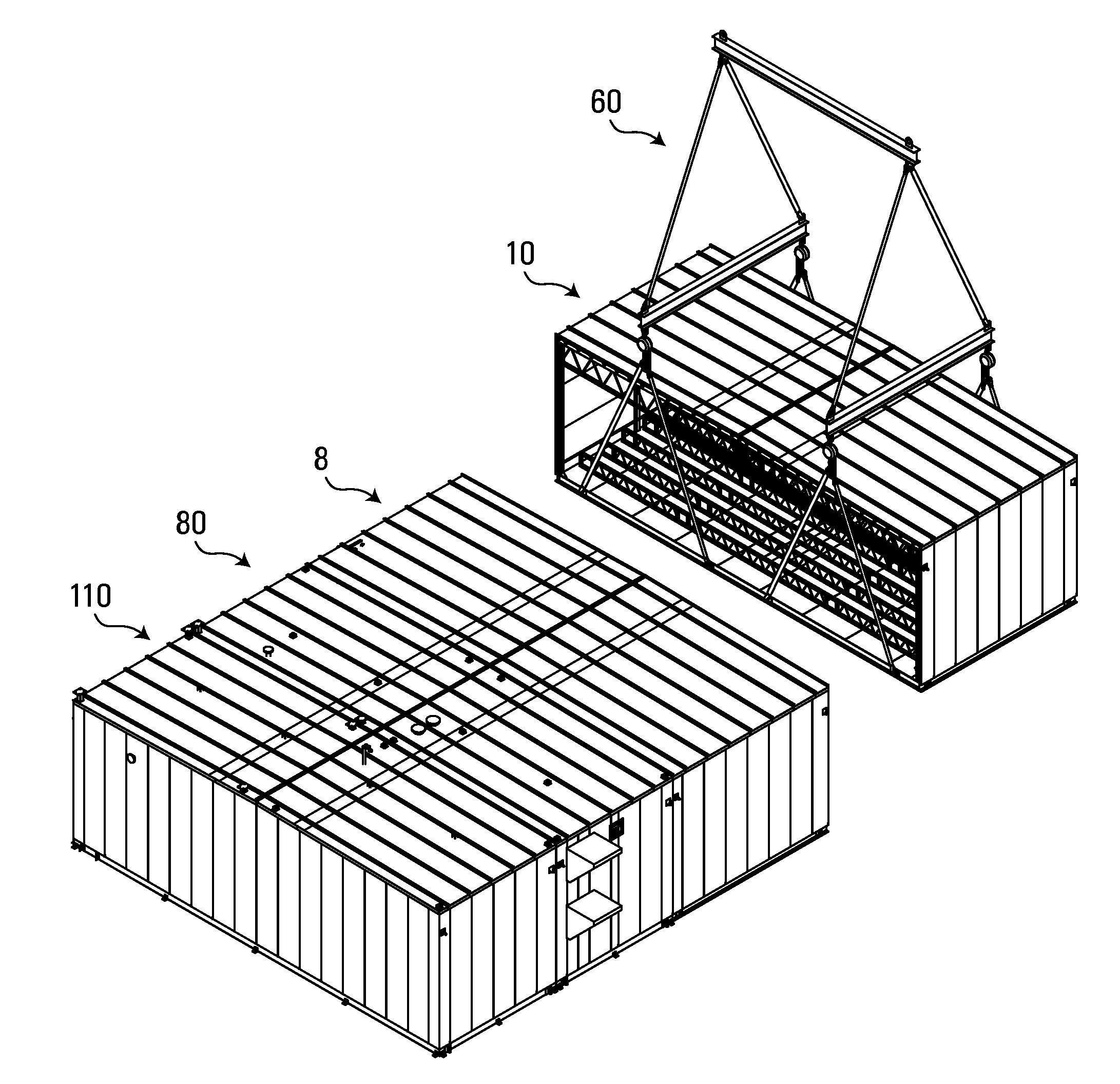

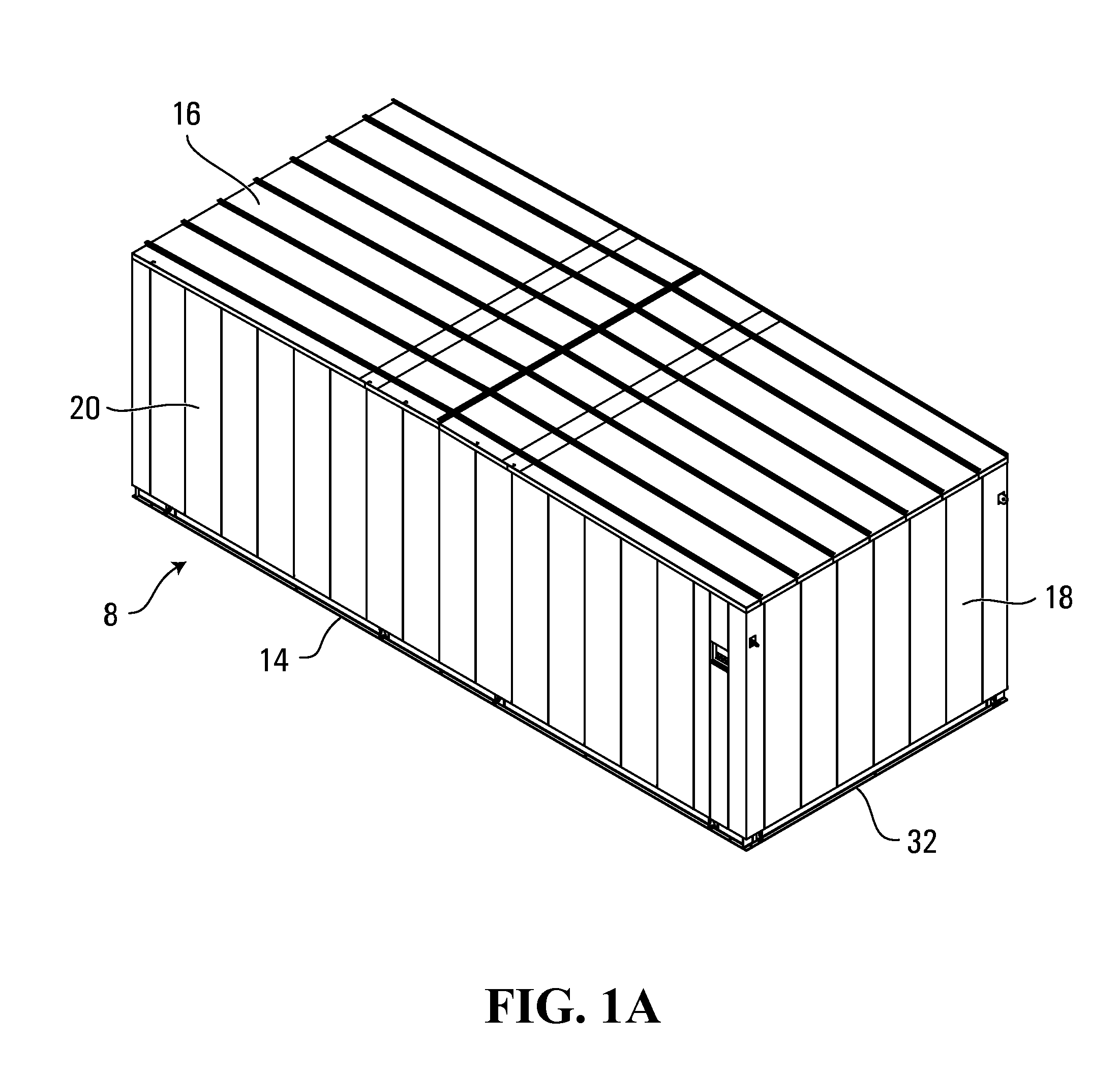

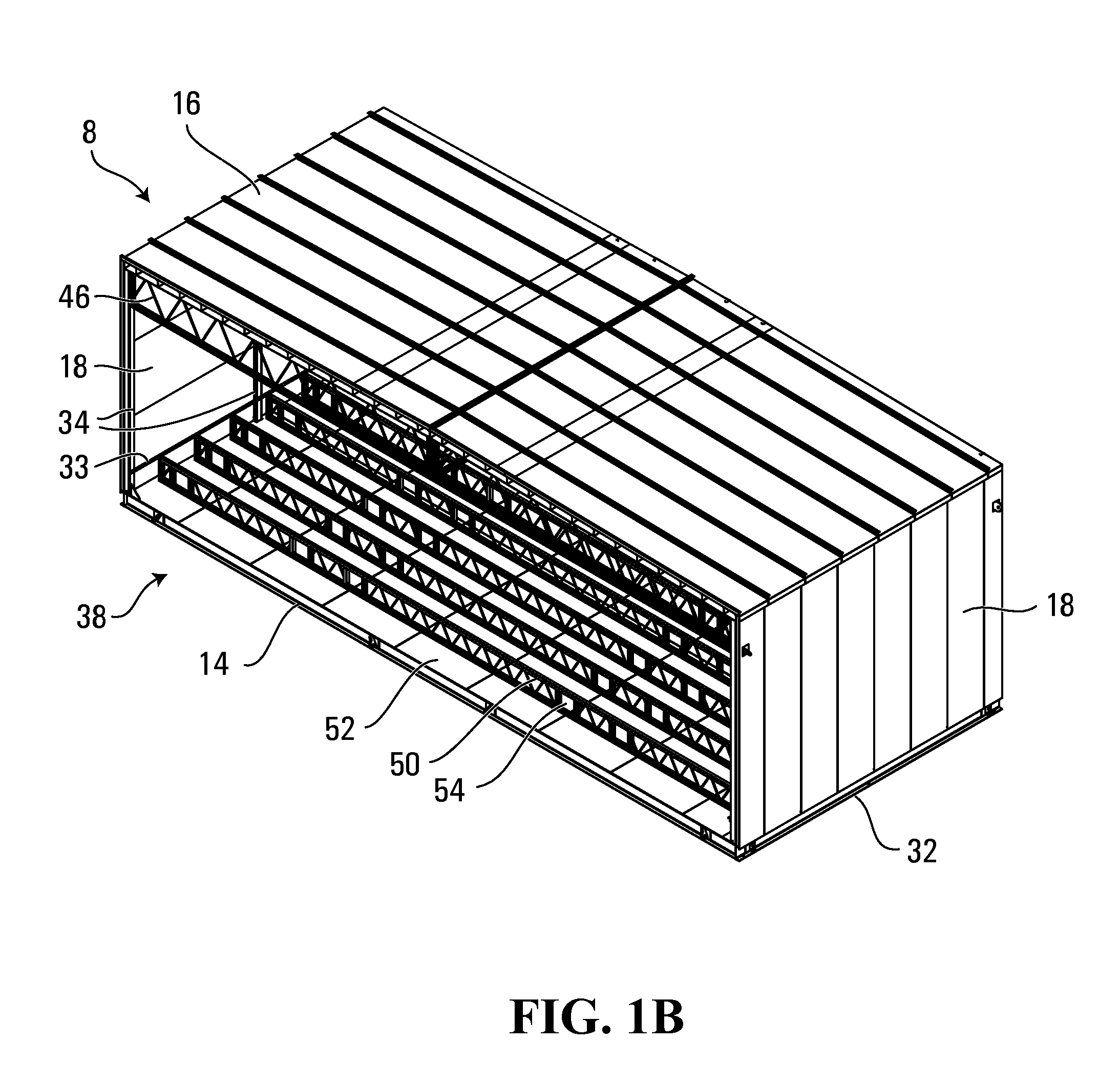

[0053]FIGS. 1A-1C, 2A-2B and 3A-3C show modular building units. FIGS. 1A-1C show a first side unit 8, FIGS. 2A-2C show an intermediate unit 10, and FIGS. 3A-3C show a second side unit 12. The units 8, 10 and 12 may be used, for example, for the construction of a modular computer room. In FIGS. 1A-1C, 2A-2B and 3A-3C, the same reference characters are used to identify the same features. The differences between the units 8, 10 and 12 will be identified.

[0054]The units 8, 10 and 12 have a base 14, a roof 16 and two opposed end walls 18. The first side unit 8 also has a first side wall 20. The second side unit 12 also has a second side wall 22. In FIGS. 1C, 2B and 3C, the units 8, 10 and 12 are shown without walls, roofs, floor plates and floor trusses for ease of viewing internal features.

[0055]As noted above, the units 8, 10 and 12 include a base 14. In the present embodiment, the base 14 is formed with a frame 24 (FIGS. 1C, 2B and 3C). The frame 24 defines a rectangular perimeter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com