Optically anisotropic element, polarizing plate, stereoscopic display device, and stereoscopic display system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0146]The present invention will further be detailed below, referring to Examples. Note that materials, amount of use, ratio, details of treatment, procedures of treatment and so forth may be modified without departing from the spirit of the present invention. It is, therefore, to be understood that the scope of the present invention is not restrictively interpreted by Examples described below.

example a

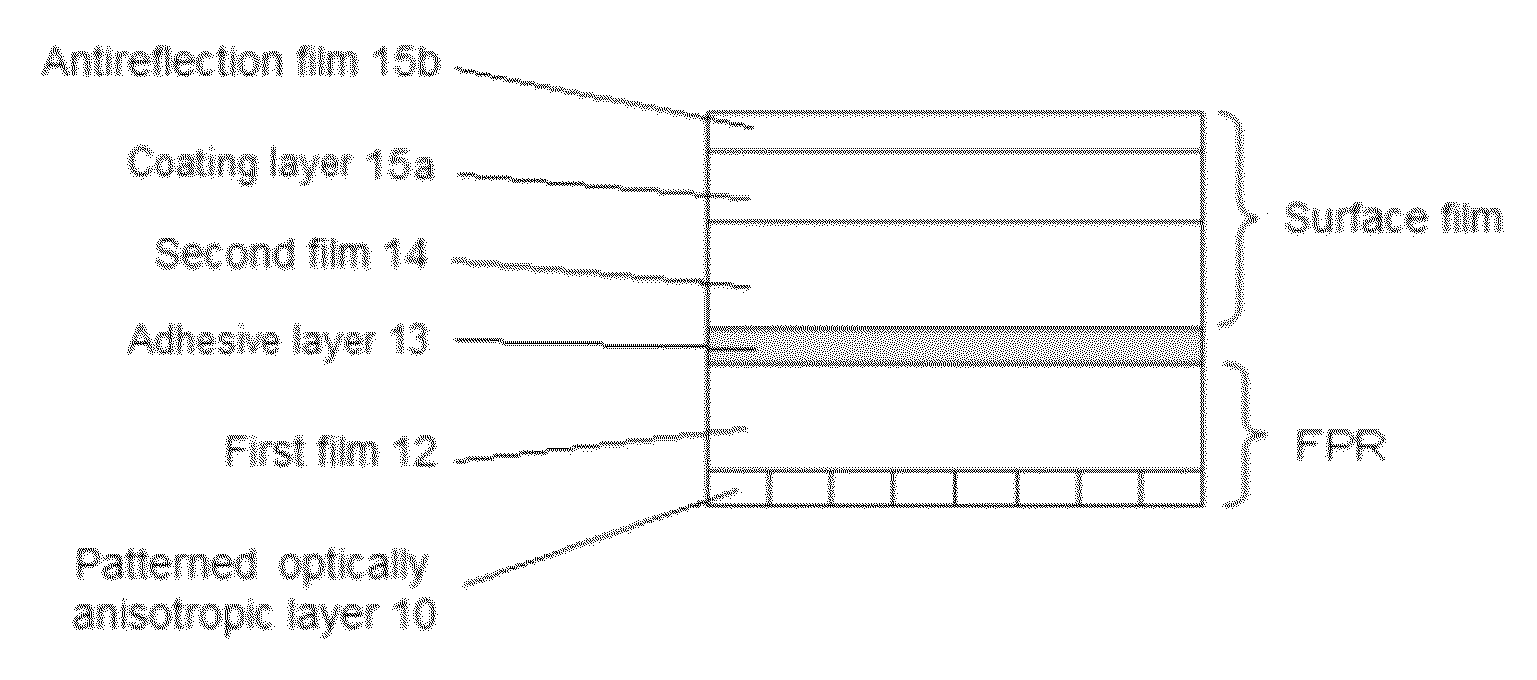

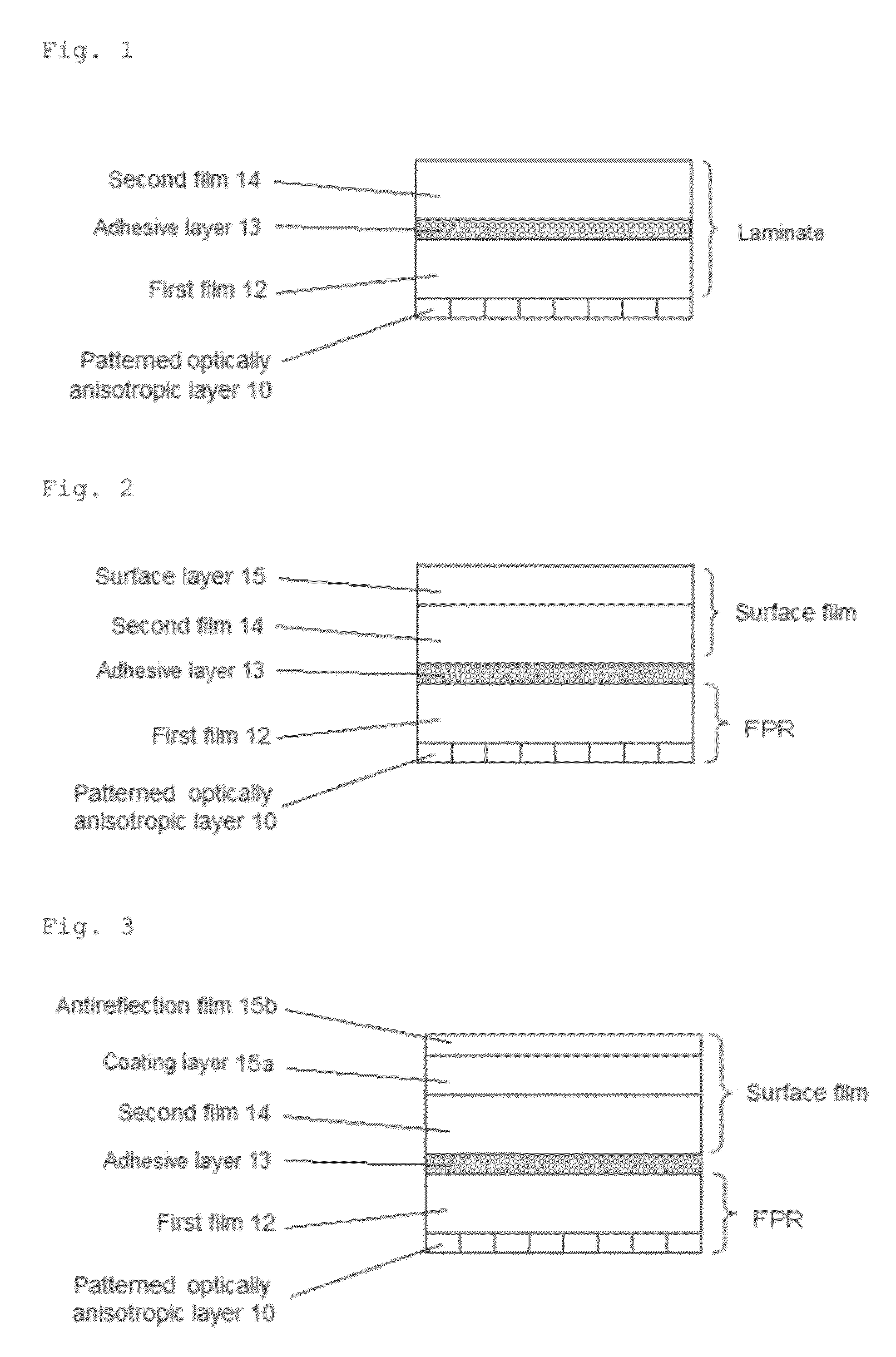

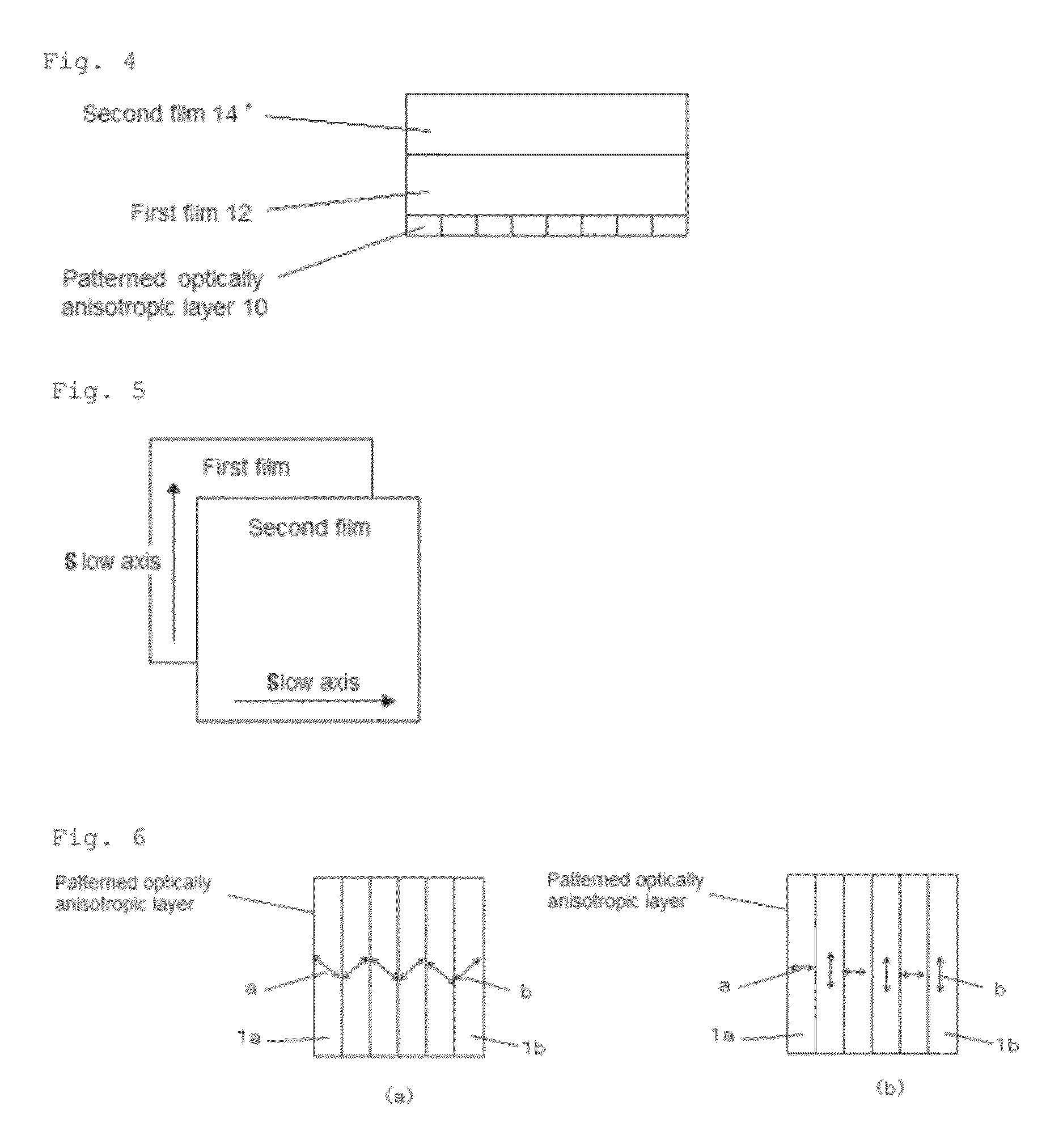

[0147]The first and second films, having optical characteristics listed in Table below were prepared. Various types of the patterned optically anisotropic layers were respectively formed on the first film, while controlling, and then fixing, the state of alignment of a liquid crystal composition, typically making use a patterned photo-alignment film obtained by exposure of light through a mask, a patterned rubbed alignment film obtained by rubbing through a mask, or a patterned alignment film obtained by controlling expression and disappearance of interaction between an additive or the like with the alignment film, to thereby manufacture the FPRs. The liquid crystal composition adopted herein contained a polymerizable rod-like liquid crystal or a polymerizable discotic liquid crystal, optionally added with an additive for controlling alignment, and also with a polymerization initiator for promoting the polymerization. The patterned optically anisotropic layer was a patterned λ / 4 lay...

example b

[0154]Next, configurations having a patterned optically anisotropic layer disposed between the third film and the fourth film were evaluated.

[0155]The third films listed in Table 3 were respectively prepared, and the patterned optically anisotropic layers were respectively formed on the third films, while controlling, and then fixing, the state of alignment of a liquid crystal composition, typically making use a patterned photo-alignment film obtained by exposure of light through a mask, a patterned rubbed alignment film obtained by rubbing through a mask, or a patterned alignment film obtained by controlling expression and disappearance of interaction between an additive or the like with the alignment film, to thereby manufacture the FPRs. The liquid crystal composition adopted herein contained a polymerizable rod-like liquid crystal or a polymerizable discotic liquid crystal, optionally added with an additive for controlling alignment, and also with a polymerization initiator for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com