High strength low mass seat mounting system for row seating

a seat mounting system and low-mass technology, applied in the field of fixed seats, can solve the problems of large stress and strain, failure fatigue of the support system, etc., and achieve the effect of low mass, high strength and reduced system mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

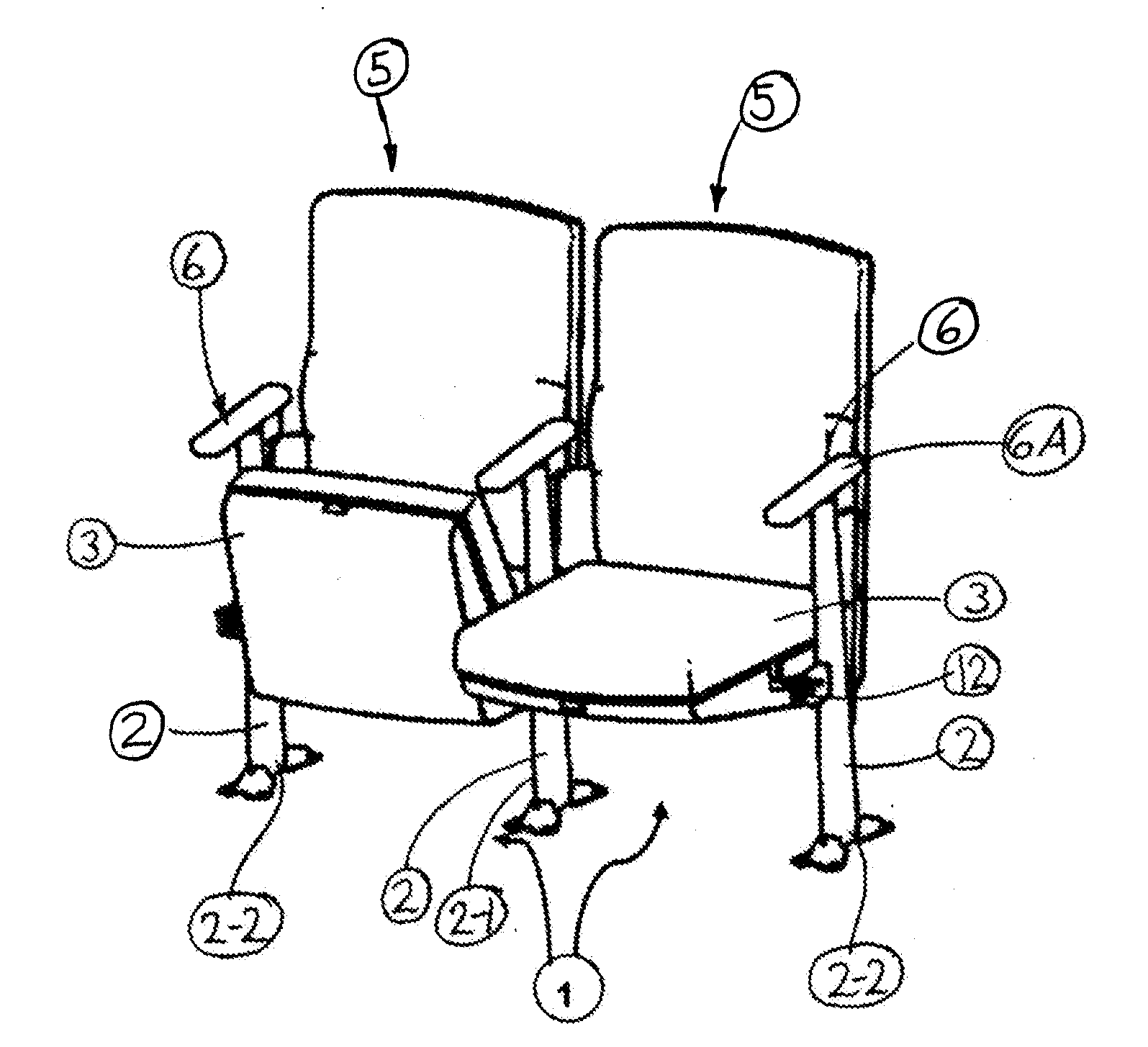

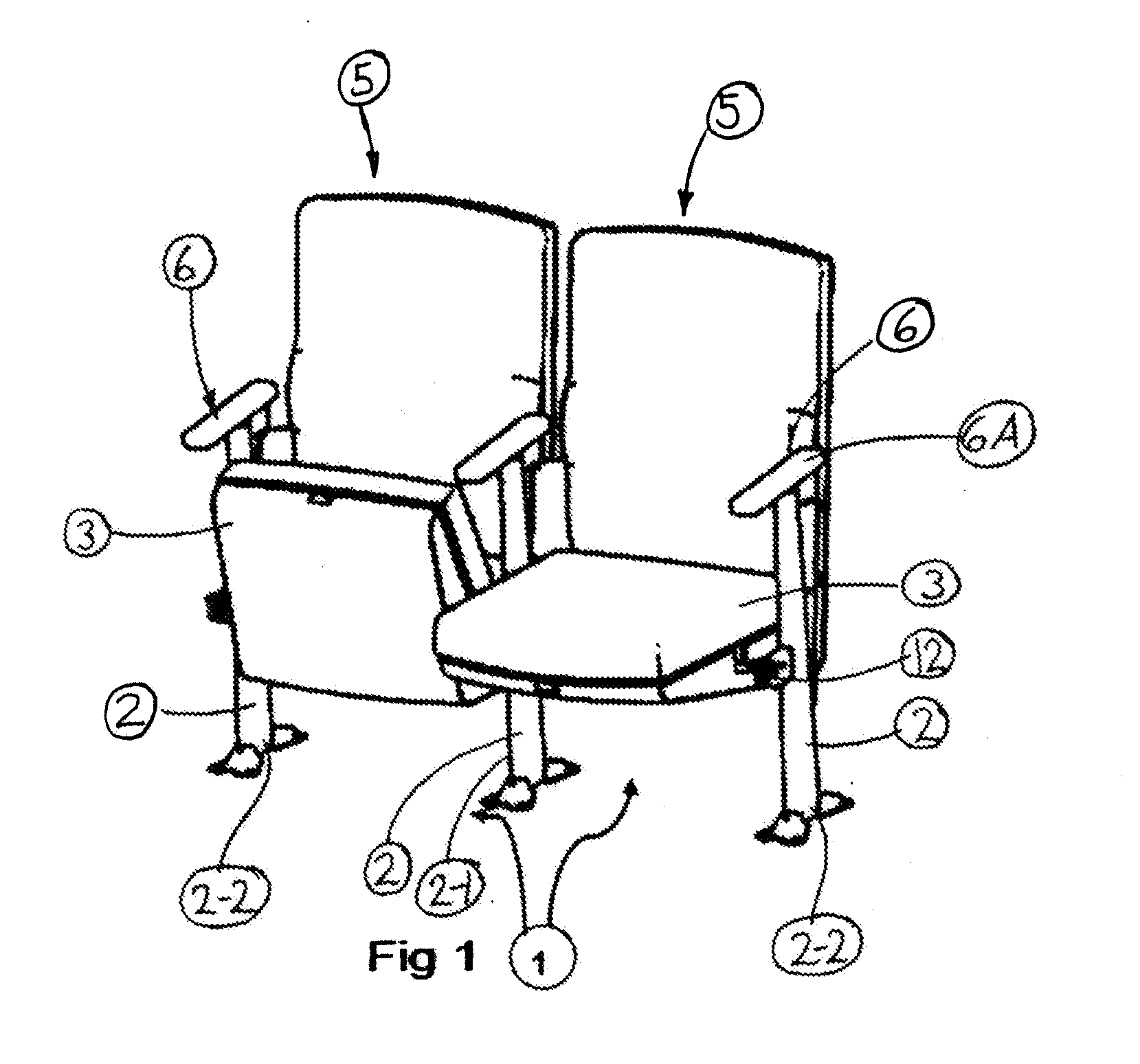

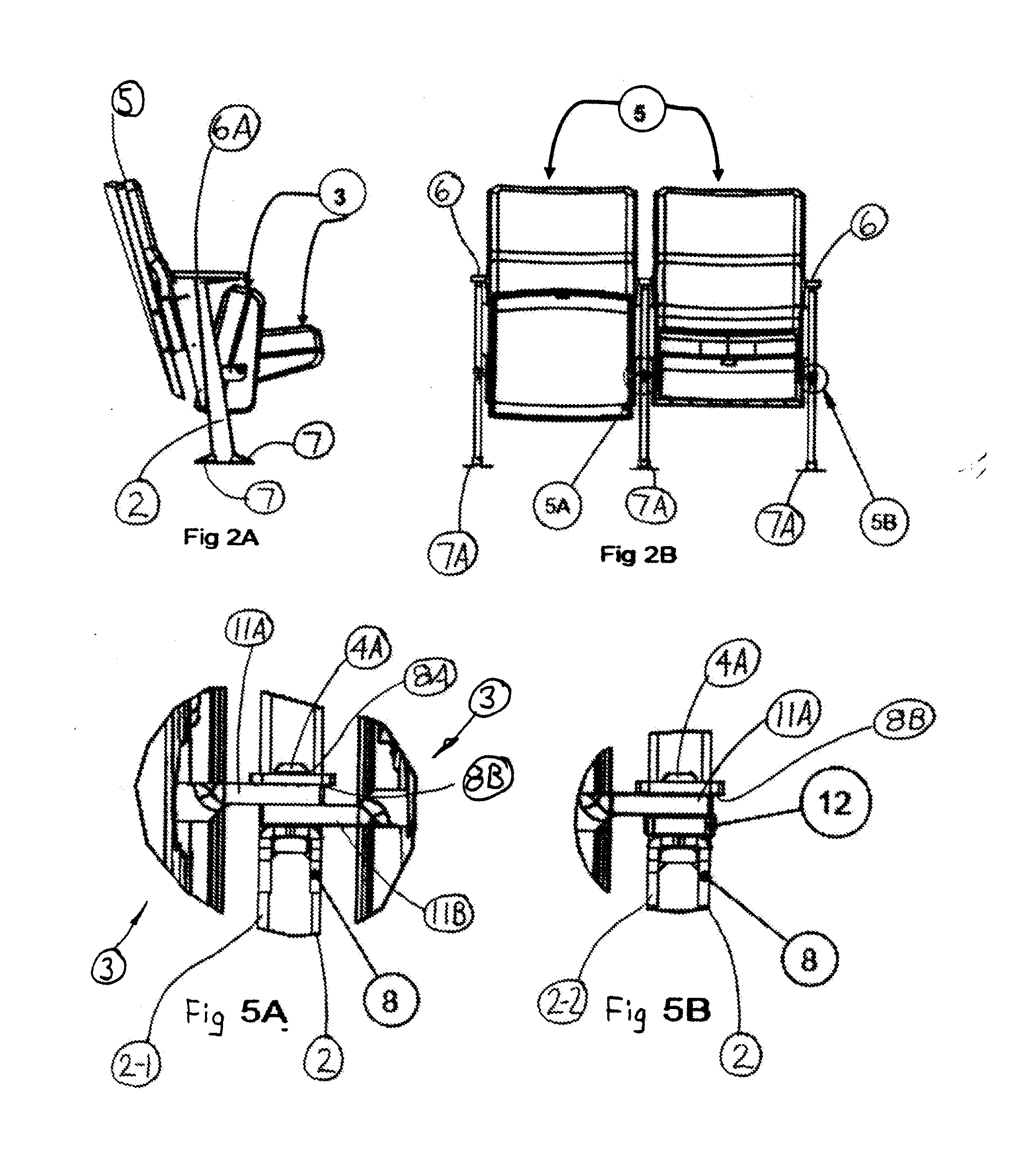

[0053]A seat mounting system for row seating is a means to support a plurality of adjacent backrest and seat assemblies 15, fixedly arranged in rows in a seating facility. Rows of seats may be arranged in a straight line or curved line. The mounting system consists of support columns or brackets affixed to a floor or riser surface, with cross members linking the supports. The support columns or brackets may include devices for mounting armrests, backrests, and seats. The seat portion of the assembly is commonly mounted on an axle or pivot rod cross member to allow the seat to be rotated from a horizontal to a vertical position when not in use.

[0054]Referring now to the drawings and the illustrative embodiments depicted therein, a seat or chair mounting assembly 1 includes a support column or standard assembly 2 that supports: a seat portion 3 via a pivot rod assembly 4; a back rest portion 5; and optionally an armrest support 6 (FIGS. 1-5) having an armrest pad 6A. The support colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com