Valve actuation apparatus of internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

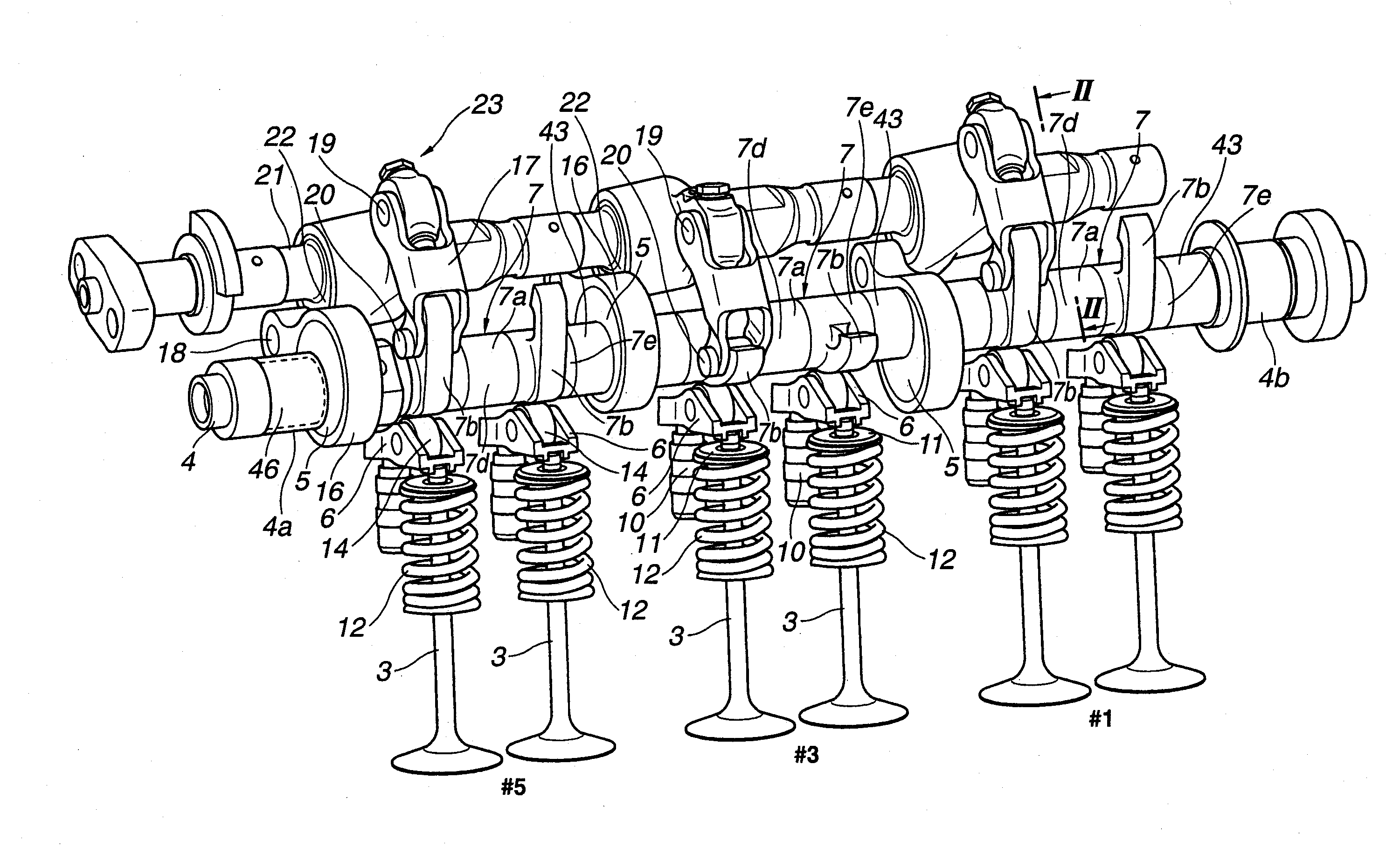

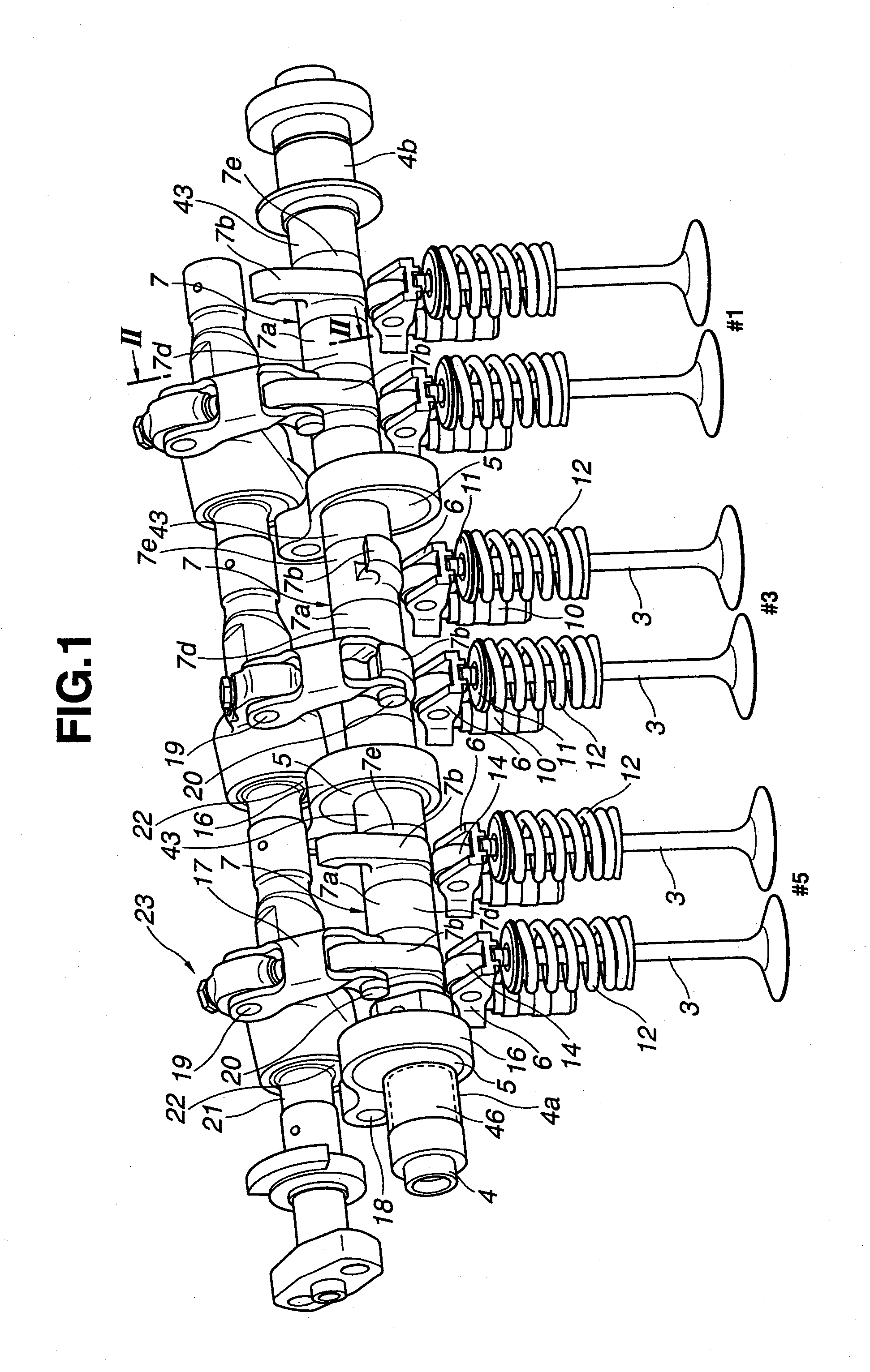

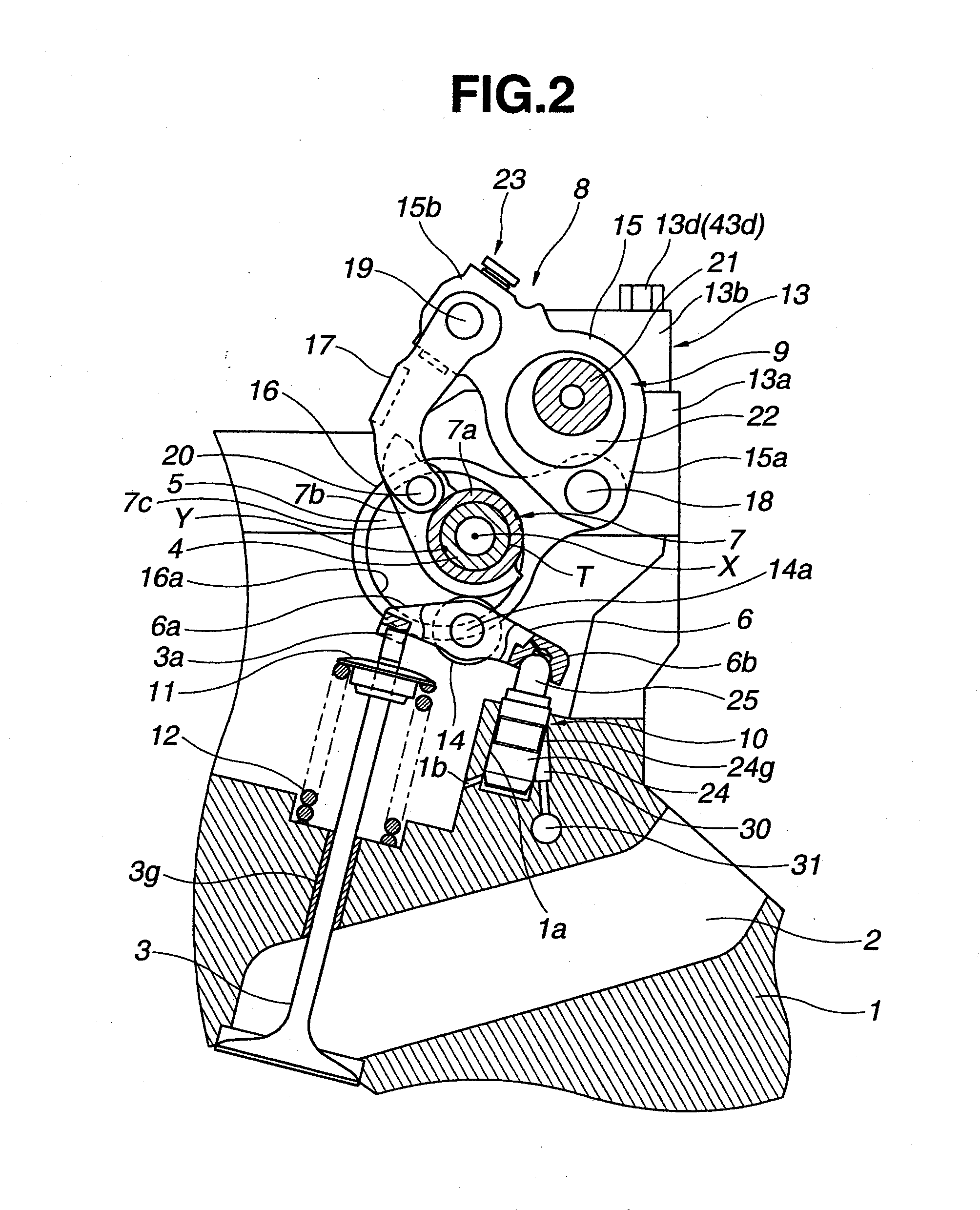

[0018]Referring now to the drawings, the valve actuation apparatus of the embodiment is exemplified in a variable valve event and lift control apparatus of the intake-valve side of a V-6 internal combustion engine whose cylinders are arranged in two banks of three cylinders. In particular, FIGS. 1-4 show the valve actuation apparatus of the embodiment, which is installed on three cylinders (i.e., No. 1 cylinder, No. 3 cylinder, and No. 5 cylinder) of one cylinder bank of the V-6 engine.

[0019]As clearly shown in FIGS. 1-3, the valve actuation apparatus of the embodiment is provided with two intake valves 3, 3 per cylinder for opening and closing a pair of intake ports 2, 2 formed in a cylinder head 1, a drive shaft 4, a rockable-cam structural member 7, a motion transmission mechanism (or a multi-nodular linkage motion converter) 8, a control mechanism 9, and a pair of hydraulic lash adjusters 10, 10. Drive shaft 4 is located above the three cylinders (#1, #3, #5 cylinders) of one cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com