Hydrogen Storage System

a technology of hydrogen storage and storage tanks, which is applied in the direction of gas/liquid distribution and storage, containers, packaging goods types, etc., can solve the problems of reducing the overall usefulness of the vehicle, the size of the hydrogen tank is impractically large, and the space allocated for the hydrogen tank or the available space in the vehicle is difficult to install, so as to reduce the stress, reduce the stress, and reduce the effect of tensile strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

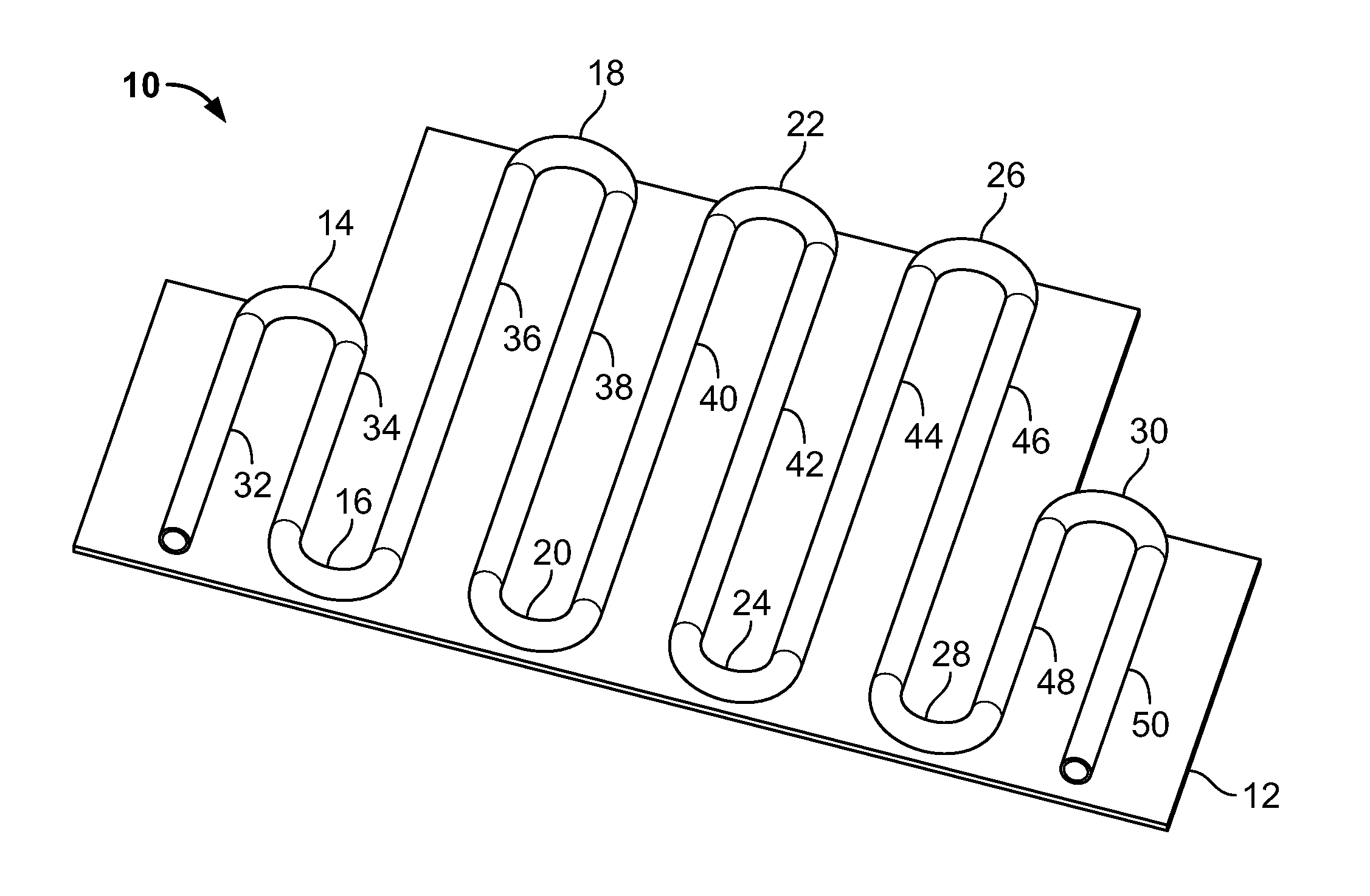

[0039]In the storage system of the present invention, all of the storage elements may be coupled to each other to form one or more containers positioned proximate each other within the boundaries of the defined space of volume V where the containers may be different in size, shape and architecture or they may all be the same in size, shape and architecture.

second embodiment

[0040]In the storage system of the present invention, the storage elements may be coupled to each other to form one or more containers each of which is positioned within the boundaries of the defined space of volume V. Additionally, one or more other containers—not formed from storage elements—can also be positioned within the boundaries of the defined space of volume V. The containers formed from storage elements and containers not formed from the storage elements all fit within the boundaries of the defined space of volume V.

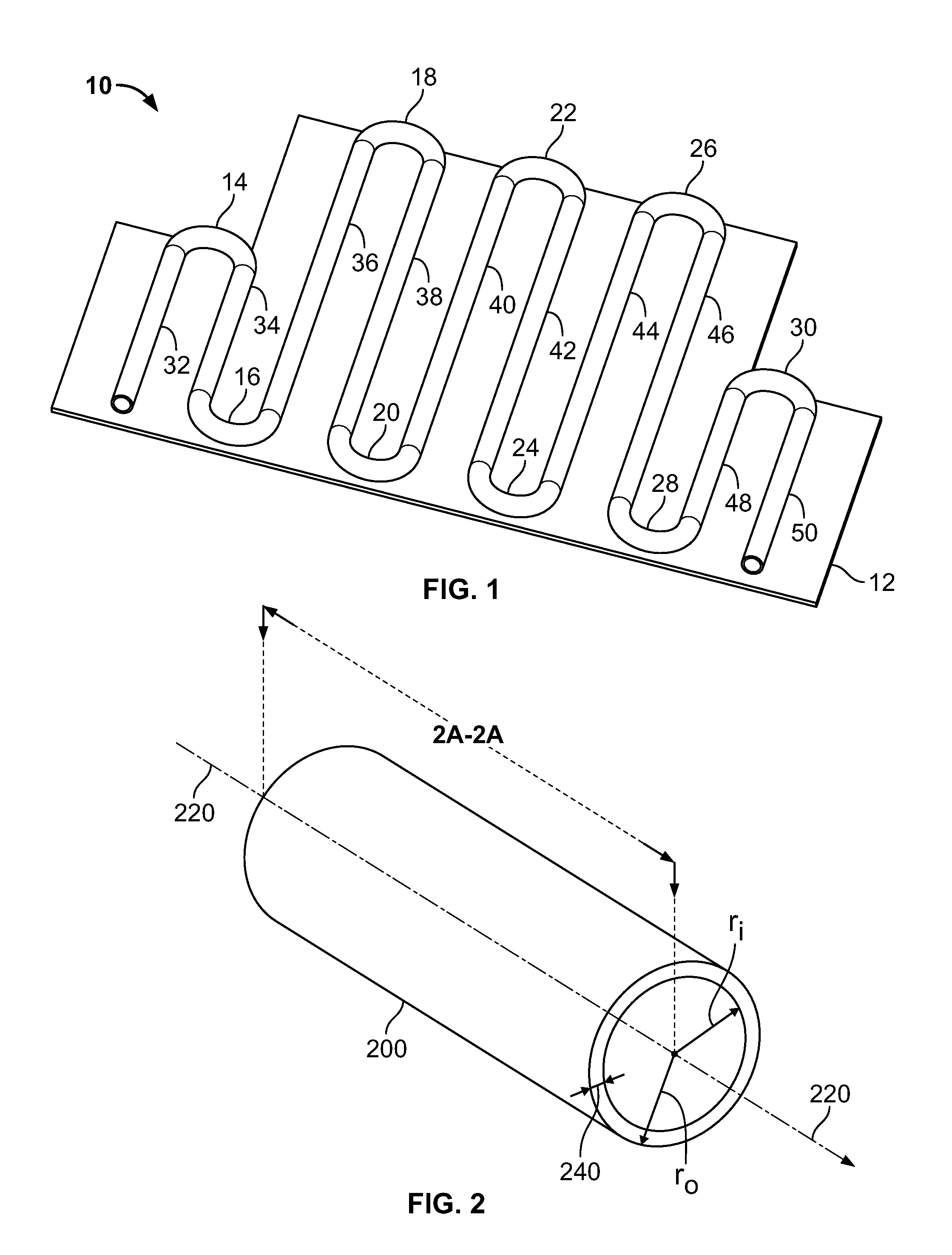

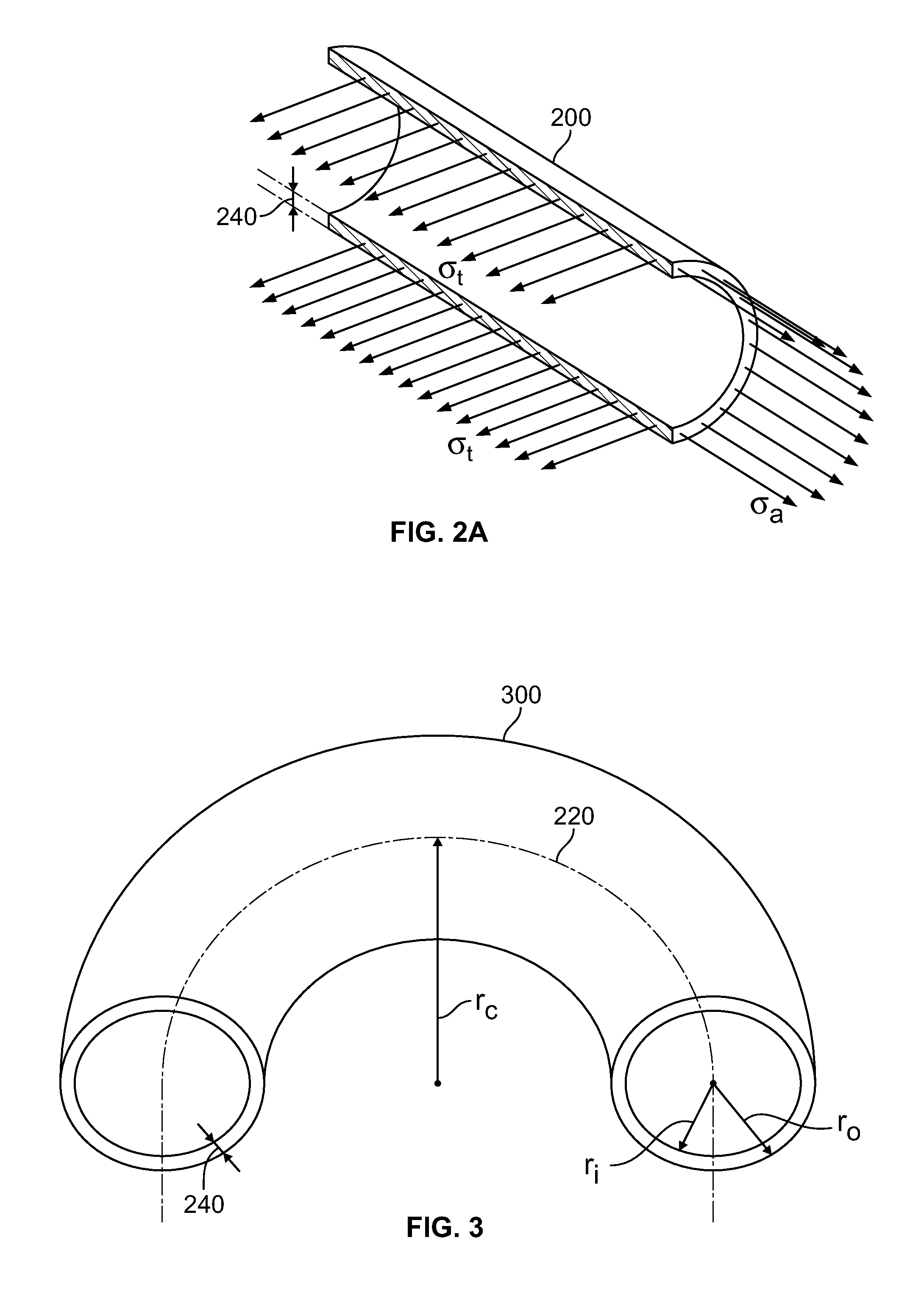

[0041]A particular implementation which can be used for the first and / or second embodiments of the present invention comprises storage elements having two types of shapes, viz., straight cylinders and bent cylinders having equal outer diameters (D0, where 2*r0=D0; r0 is the outer radius) and inner diameters (Di, where 2*ri=Di; ri is the inner radius); all of the bent cylinders have equal curve radii (rc). The curve radius for each of the bent cylinders is equa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com