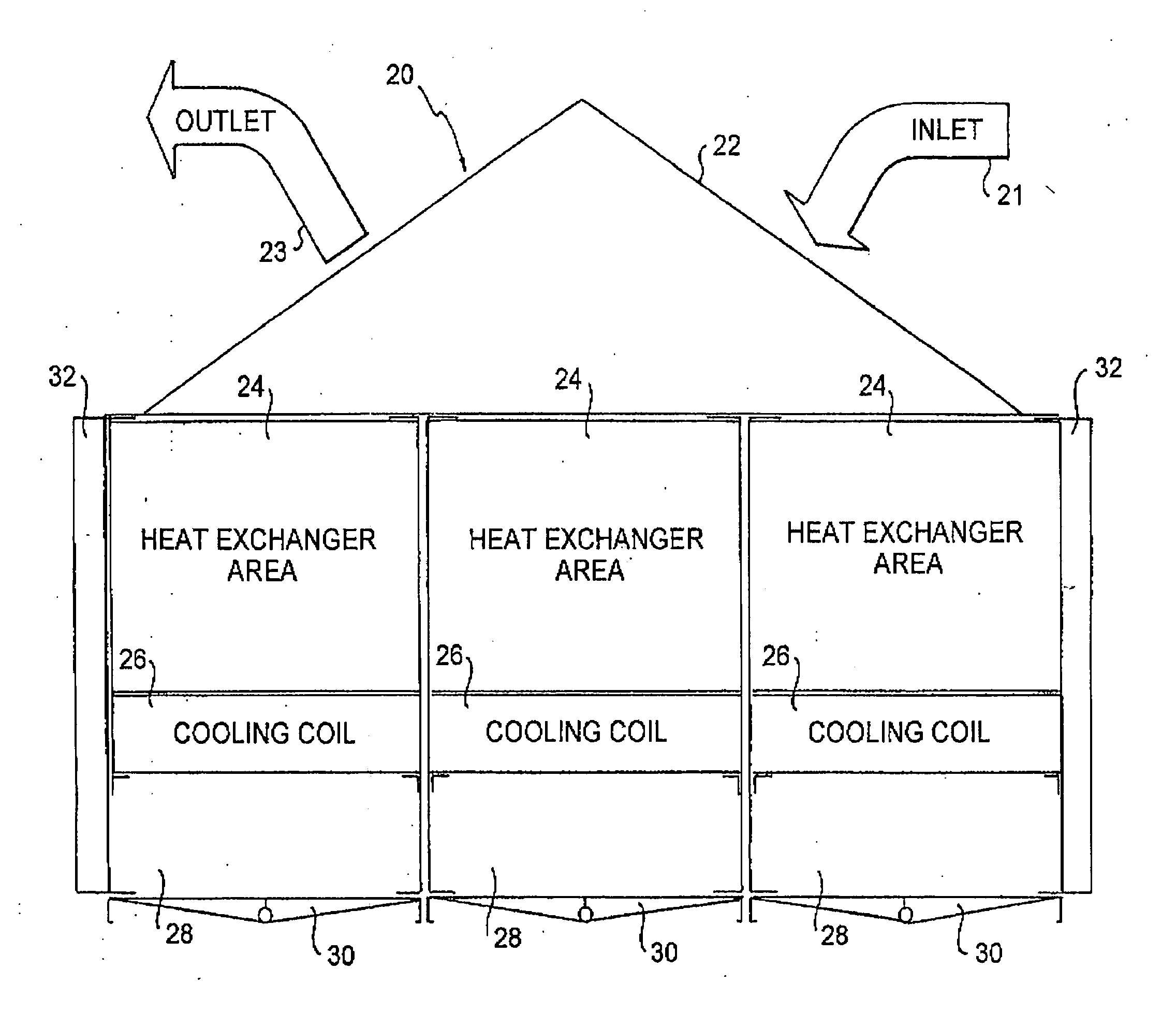

Modular drain pan assembly, with seamless floor, for horizontally positioned dual-pass cooling coils

a dual-pass cooling coil and drain pan technology, applied in the field of drain pans, can solve the problems of requiring seams, affecting the service life a potential source of microbial contamination of the drain pan, so as to facilitate the overall length of the drain pan can be increased, and the effect of facilitating the initial assembly or service change-ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

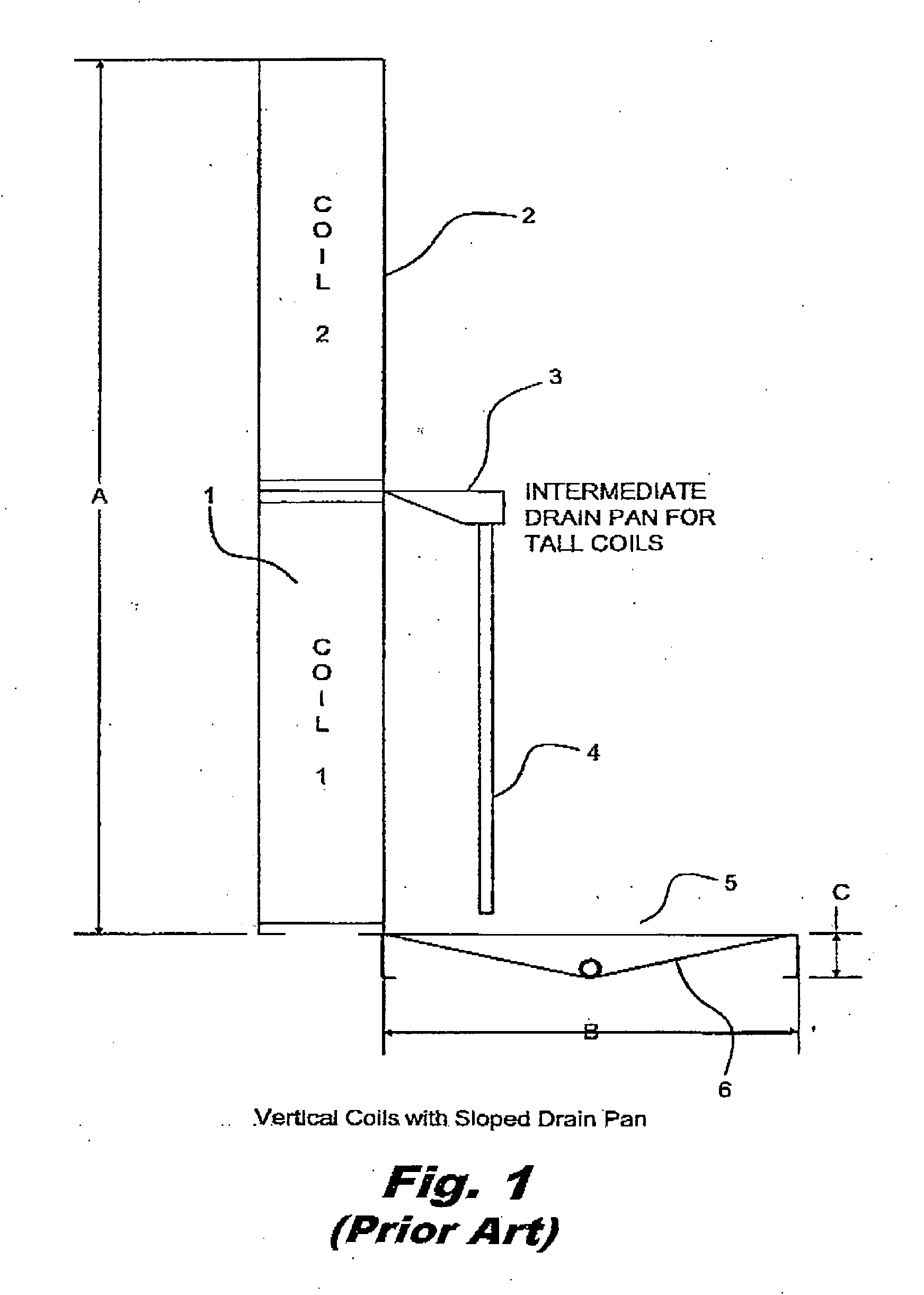

[0037]FIG. 1 shows a prior art tall vertical cooling coil partitioned into a bottom coil 1 with a coil 2 atop. For very tall coils such as this, an intermediate drain pan 3 can be used with a conduit 4 to a main drain pan 5 at the bottom. Note that although the height “A” may be great, the drip surface is modest for this vertically oriented situation and can be serviced by drain pan 5 of modest dimensions (width “B” and height “C”) and sloping bottom 6.

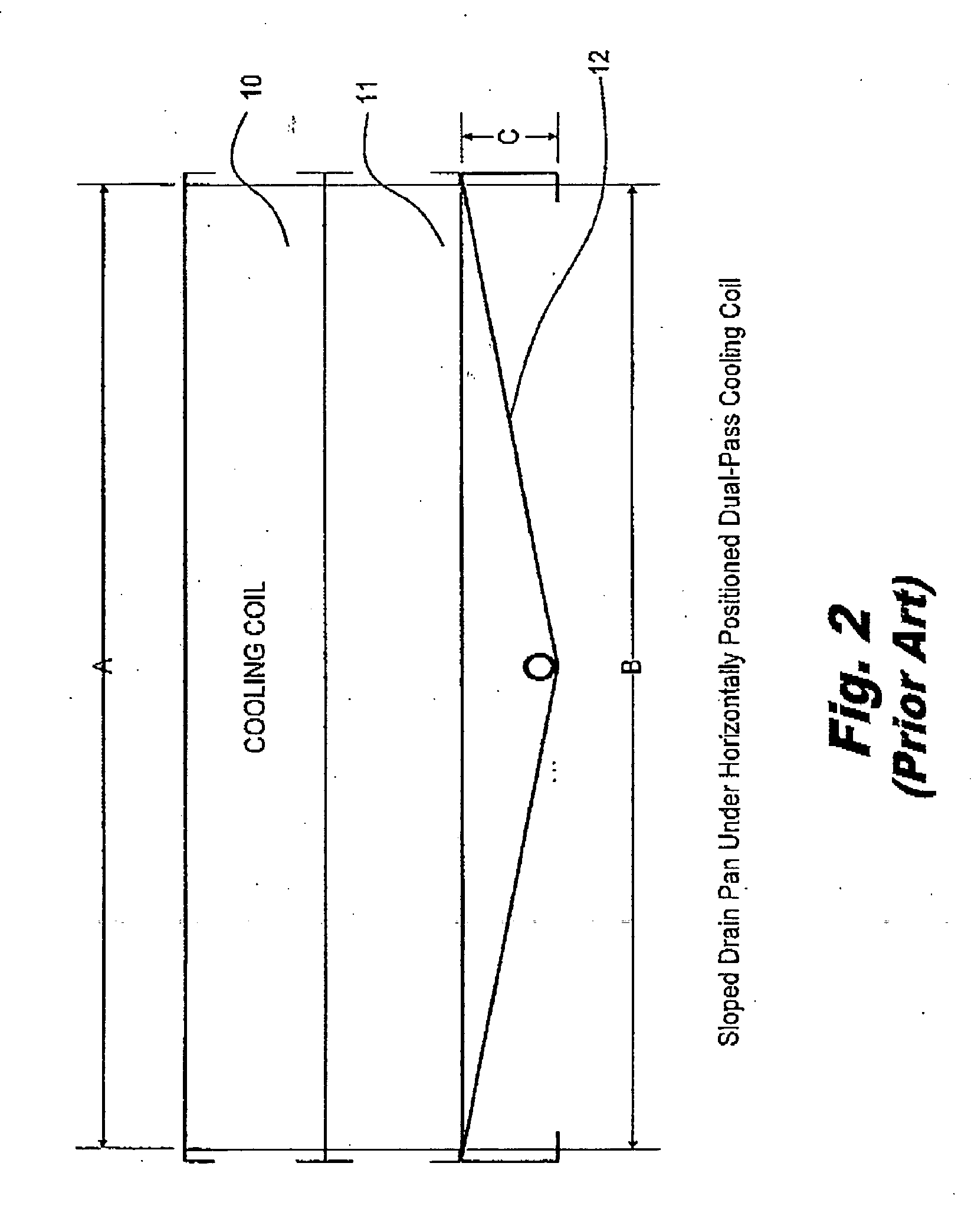

[0038]FIG. 2 shows a prior art horizontal cooling coil 10 being serviced by a drain pan 11 beneath with a sloping bottom of equivalent bottom slope 12 to that of slope 6 shown in FIG. 1. The large size of the required single pan 11 is of equivalent area to the drip area of horizontal cooling coil 10. It is noted that the length “A” of cooling coil 10 (laid horizontally) must equal the width “B” of pan 11. Height dimension “C” of pan 11 is also greater than that of pan 5 in FIG. 1 to maintain the equivalent slope 12. It is also noted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com