Rotary Drilling Rig Split Bushing

a rotary drilling rig and bushing technology, applied in the direction of drilling pipes, shock absorbers, mechanical equipment, etc., can solve the problems of variable stress on the drilling bit and consequently on the drill string, tremendous torque required to turn the drill string in the rotary drilling rig, and tremendous forces on the drilling equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

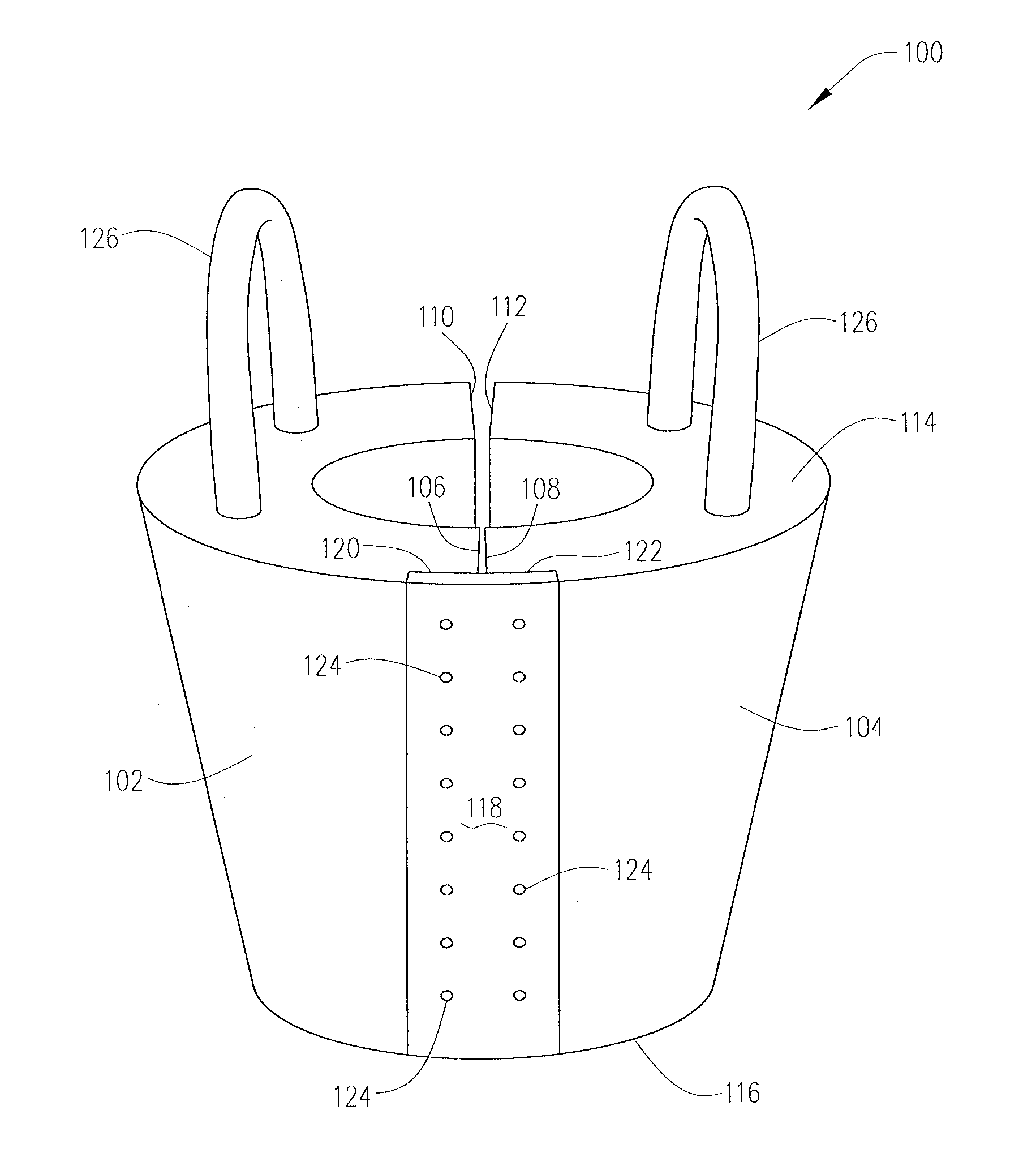

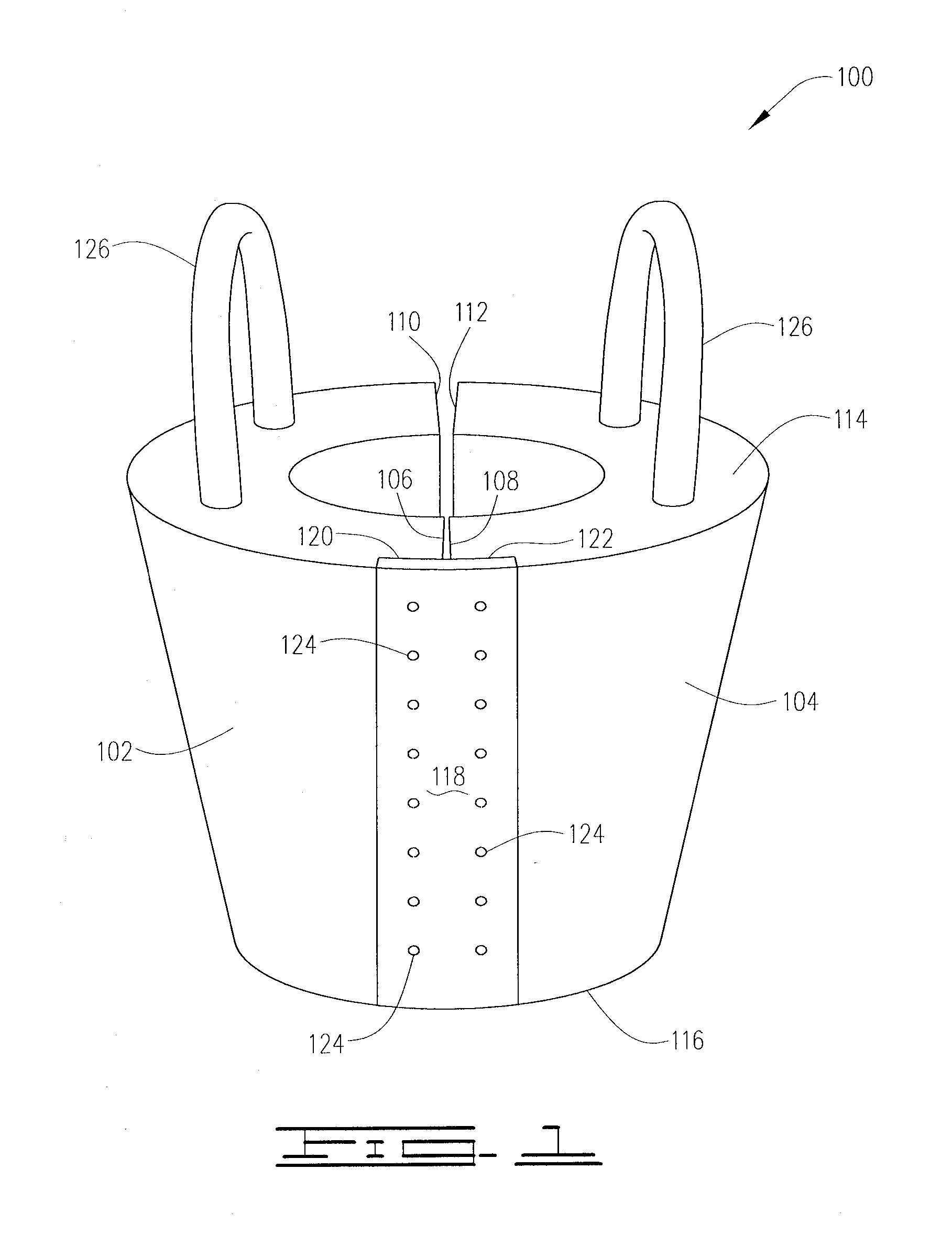

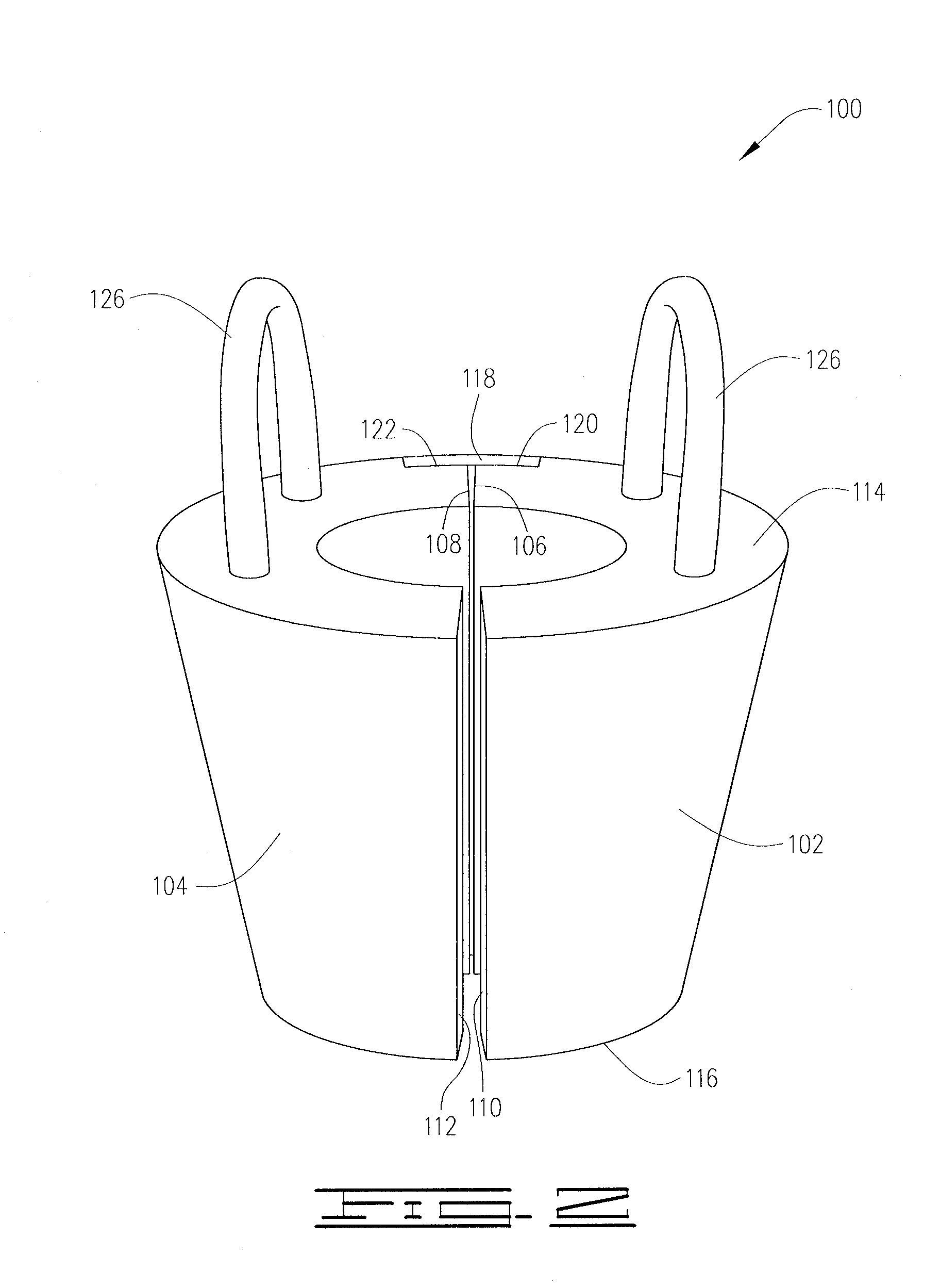

[0019]FIG. 1 shows the rotary drilling rig split bushing 100. It is comprised of a first half 102 and a second half 104 (these two pieces will be referenced herein as “halves”). The first half 102 has a first end 106 and a second end 112. Similarly, the second half 104 has a first end 108 and a second end 112. The bushing 100 has a top 114 and a bottom 116. The halves define a portion of a cone and they define therethrough a hole sized to receive the drill string. The broader end of the cone is at the top 114 with the narrower end at the bottom 116. The diameter of the hole defined therein is constant from top 114 to bottom 116, and thus, the wall thickness of the halves is greater at the top than at the bottom.

[0020]The first end 106 defines therein a first receiver 120; similarly, the second end 112 defines therein a second receiver 122. The receivers 120 and 122 are sized to receive the hinge piece 118 therein. Preferably, the hinge piece 118 defines a plurality of holes therein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com