Air conditioner

a technology for air conditioners and compressors, applied in mechanical equipment, refrigeration components, light and heating equipment, etc., can solve the problems of excessive evaporation or condensation capability of outdoor heat-exchangers, excessive discharge pressure of compressors, and difficult operation, so as to maintain the reliability of compressors and high pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Configuration of First Embodiment

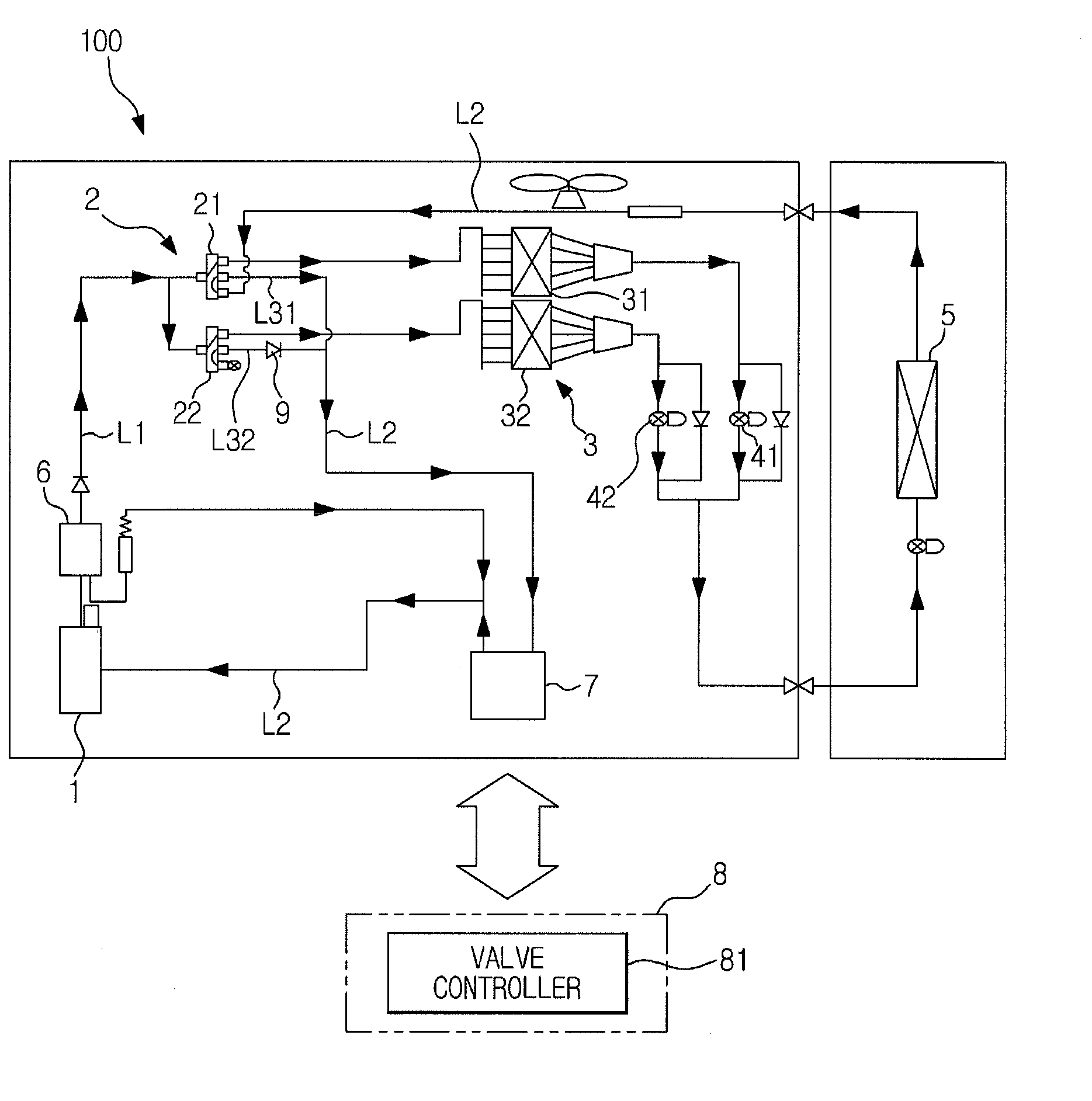

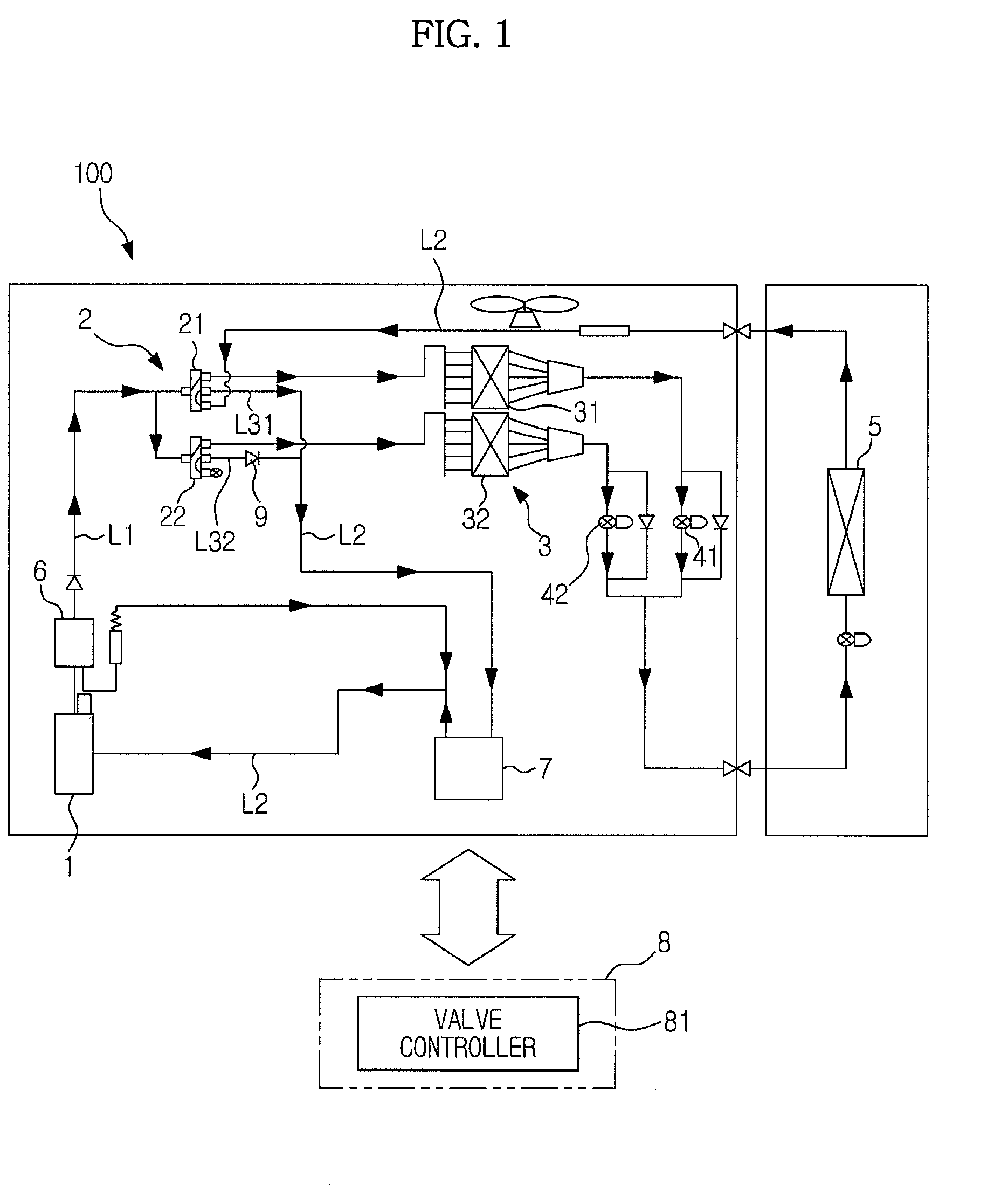

[0035]The first-described embodiment of the present disclosure will now be described with reference to the drawings.

[0036]Referring to FIG. 1, an air conditioner, designated by reference numeral 100, according to the first-described embodiment includes a refrigerant circuit constructed by annular connection of a compressor 1, a 4-way valve unit 2, an outdoor heat-exchanger unit 3, and an indoor heat-exchanger unit 5. In the air conditioner 100, the 4-way valve unit 2 is used to connect a connection for a discharge port or a suction port of the compressor 1 to any one of the outdoor heat-exchanger unit 3 or the indoor heat-exchanger unit 5, such that each heat-exchanger unit functions as a condenser or an evaporator to enable selective switching of room cooling and room heating. In the air conditioner 100 according to the first-described embodiment, to change heat-exchange capabilities of the outdoor heat-exchanger unit 3 based on outside temperature ...

second embodiment

Configuration of Second Embodiment

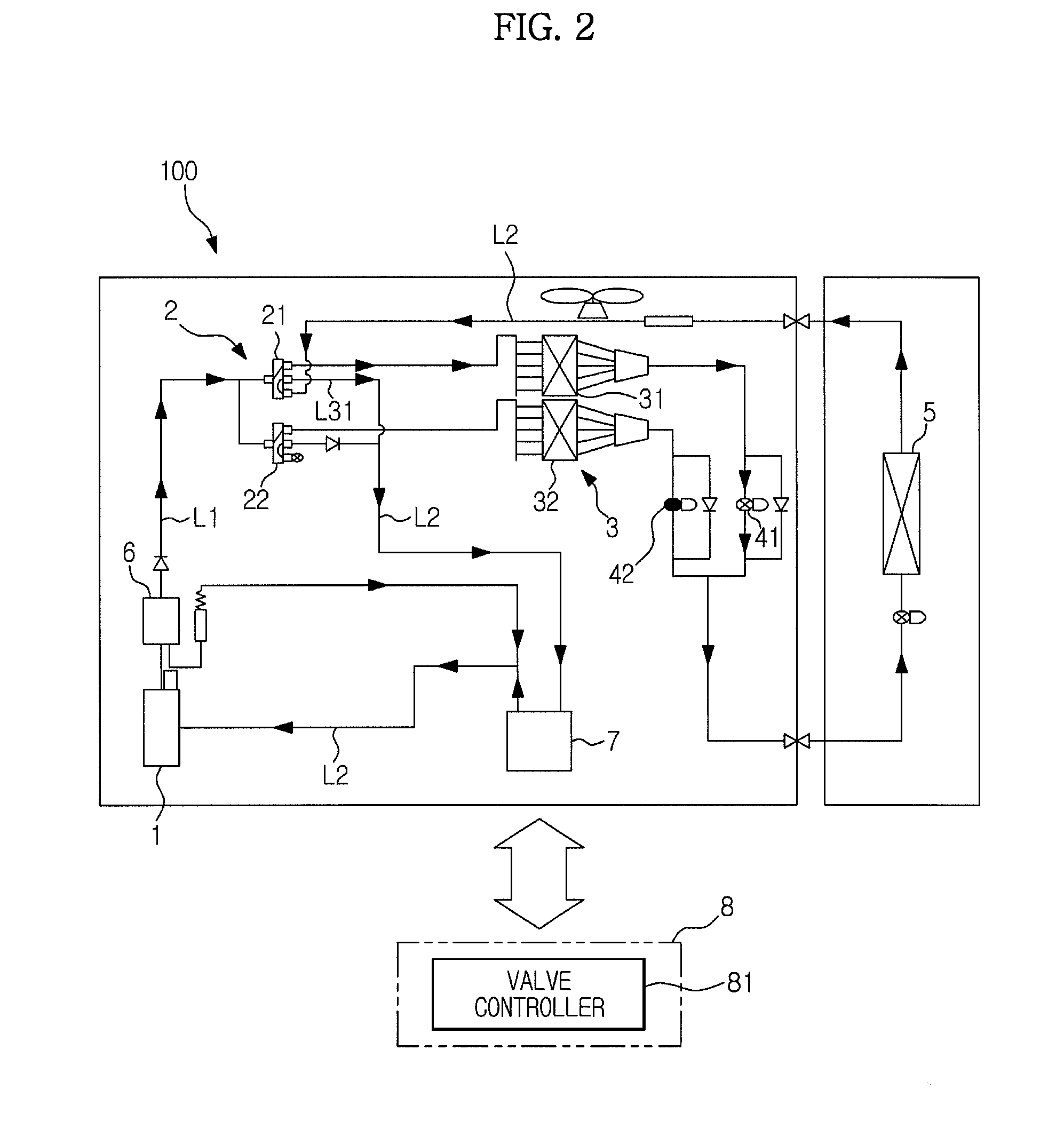

[0056]The air conditioner 100 according to the secondly-described embodiment of the present disclosure will now be described. Elements corresponding to those of the air conditioner 100 of the first-described embodiment will be designated by the same reference numerals.

[0057]The air conditioner 100 of the secondly-described embodiment includes not only a configuration for variable capacity of the outdoor heat-exchanger unit 3 via switching of flow of refrigerant to any one of a plurality of outdoor heat-exchangers, but also a configuration for defrosting of each outdoor heat-exchanger.

[0058]More specifically, the air conditioner 100 of the secondly-described embodiment, as illustrated in FIG. 7, differs from the air conditioner 100 of the first-described embodiment with respect to a configuration of the 4-way valve unit 2. Additionally, the air conditioner 100 of the secondly-described embodiment further includes an auxiliary heat-exchanger 33 provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com