Toilet flushing device

a technology for toilets and toilets, applied in toilets, water installations, constructions, etc., can solve the problems of many inconveniences during the operation of the toilet, leakage and inefficiency of the water used, and bending laterally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

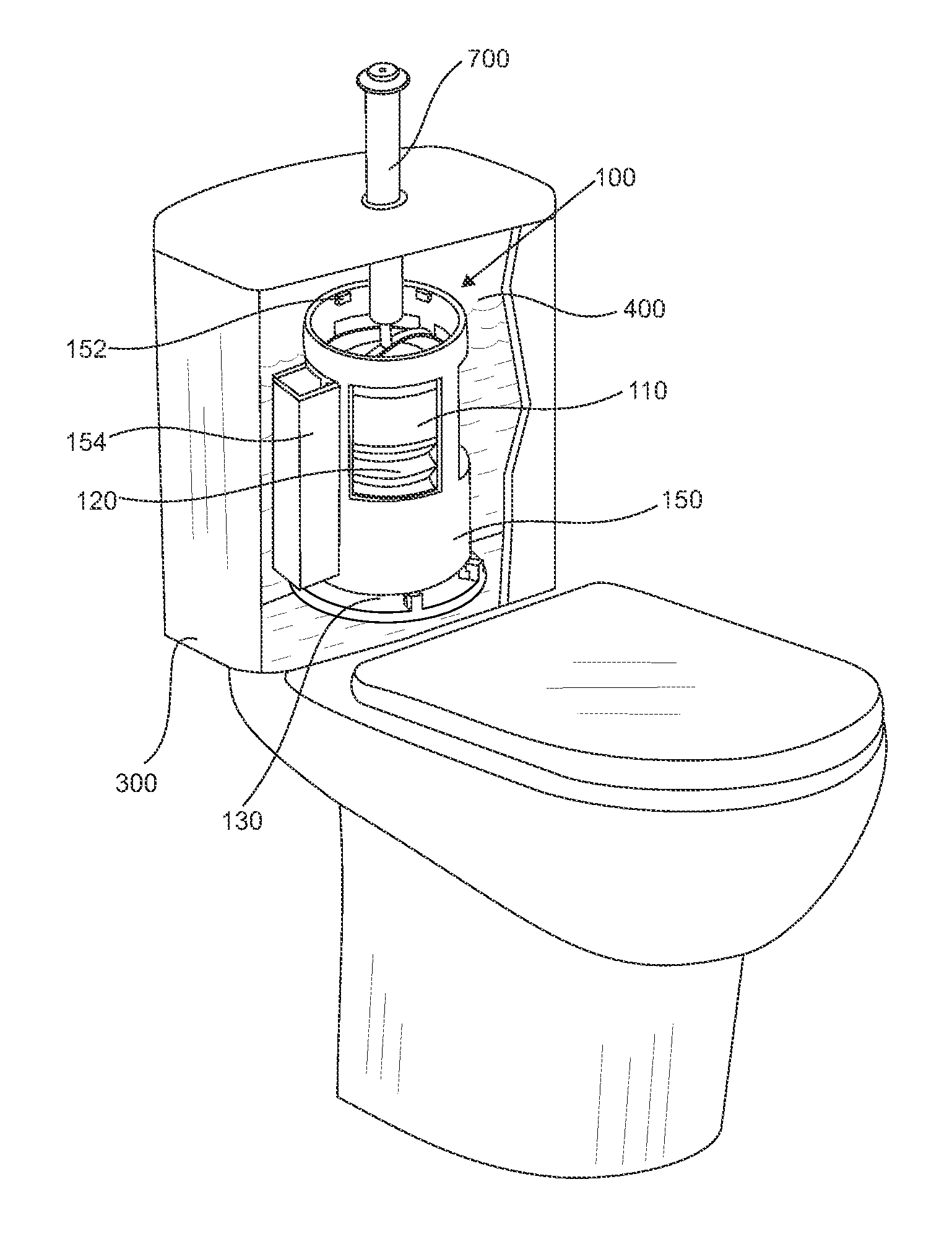

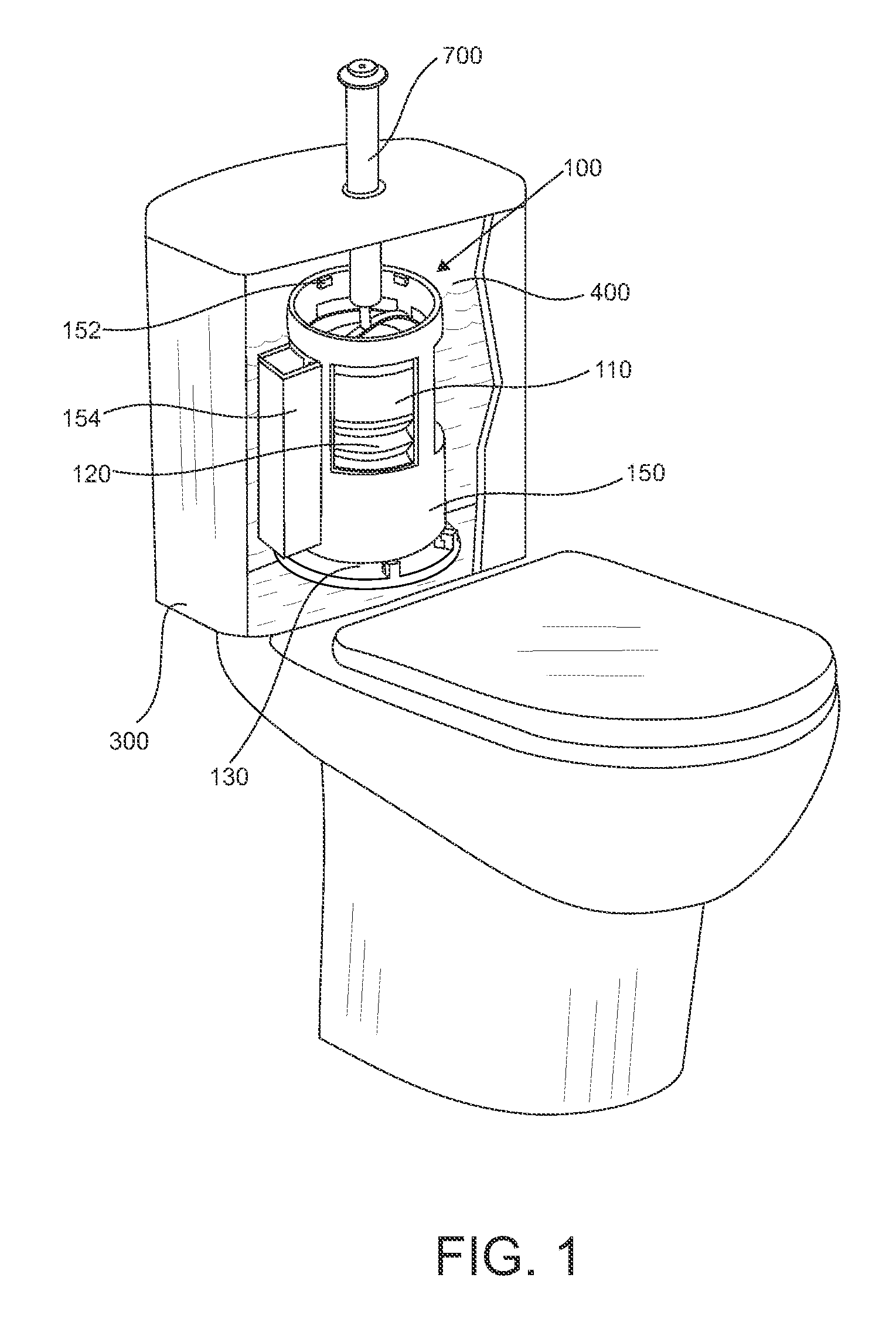

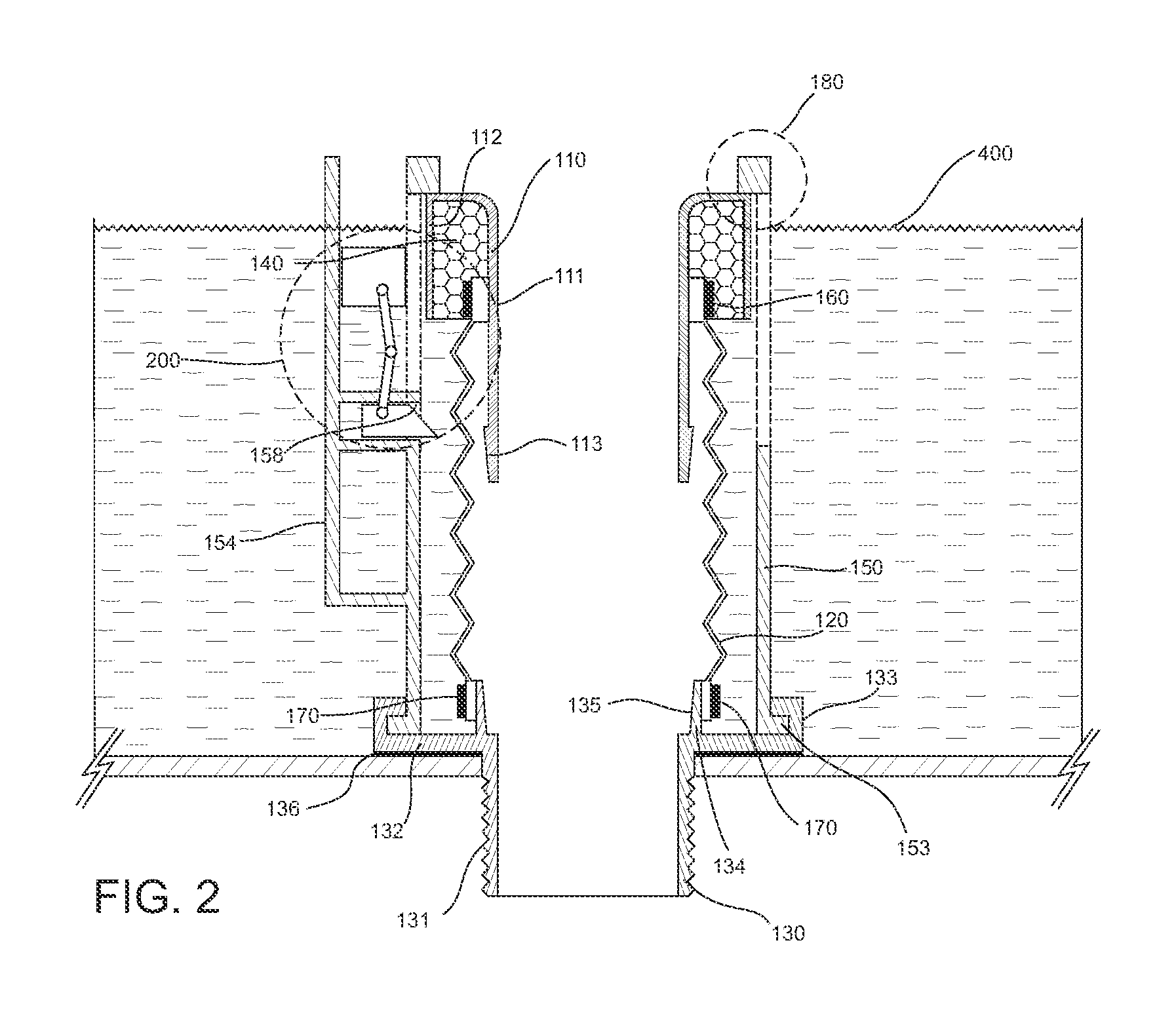

[0040]Having now more particular reference to the drawings and more specifically FIG. 1 to FIG. 3 there is shown a preferred embodiment of the toilet flushing device 100 of the present invention located inside the toilet cistern at its rest position. The toilet flushing device 100 comprises a sliding conduct 110 extending upwardly and rising above the maximum water level 400 into a cistern 300; a flexible sleeve 120 interconnected to the sliding conduct 110 and to a base support 130; a base support 130 extending upwardly and downwardly from beyond the bottom surface of the cistern 300; floating means 140 for moving the sliding conduct 110 upwards along the inner wall of an external guide cylinder 150; first fixing means 160 for fixing the flexible sleeve 120 to the sliding conduct 110; second fixing means 170 for fixing the flexible sleeve 120 to the base support 130; an external guide cylinder 150 having a length enough to rise above maximum water level 400 into the cistern 300, sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com