More sustainable biodegradable foamed zipper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

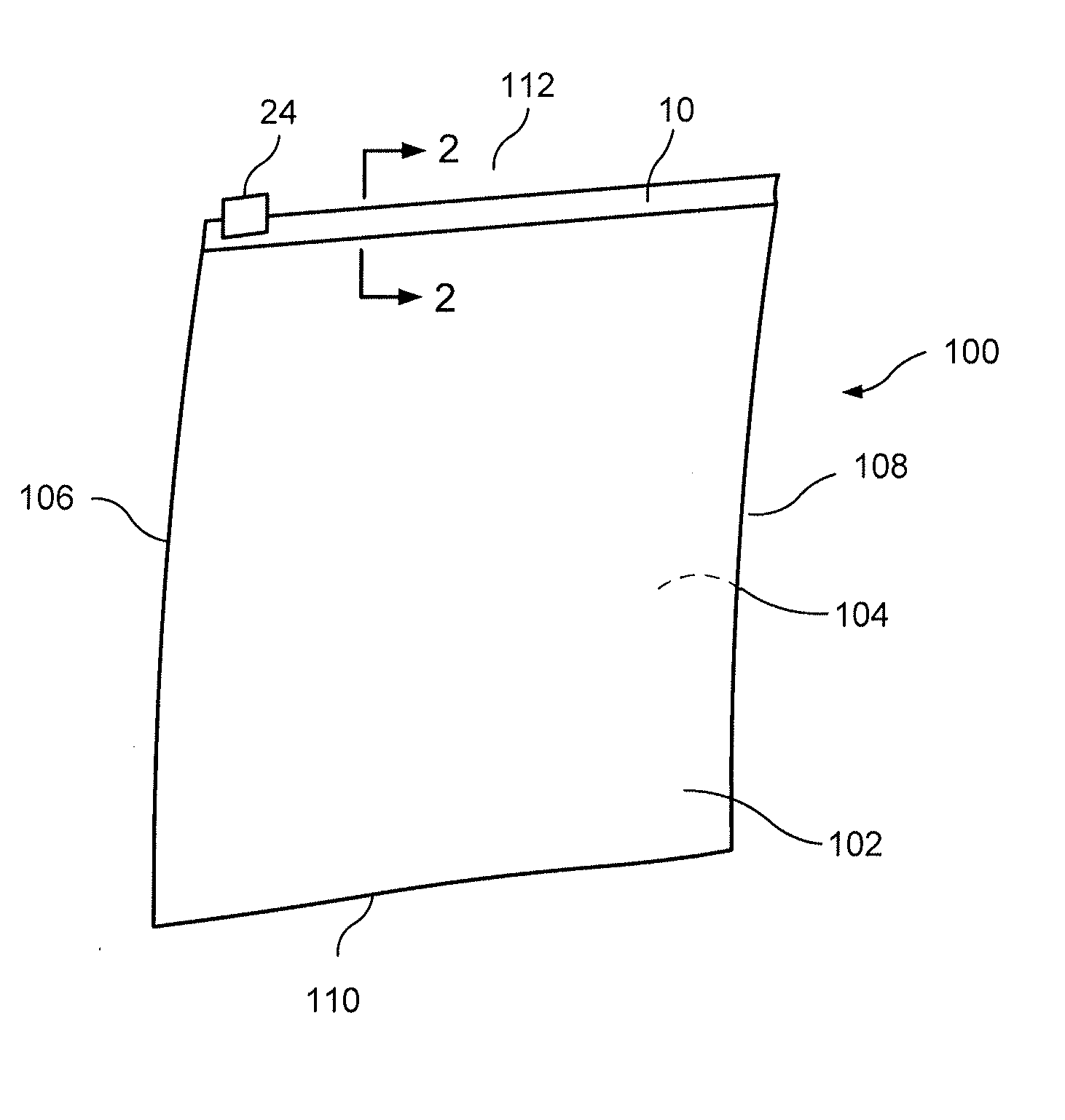

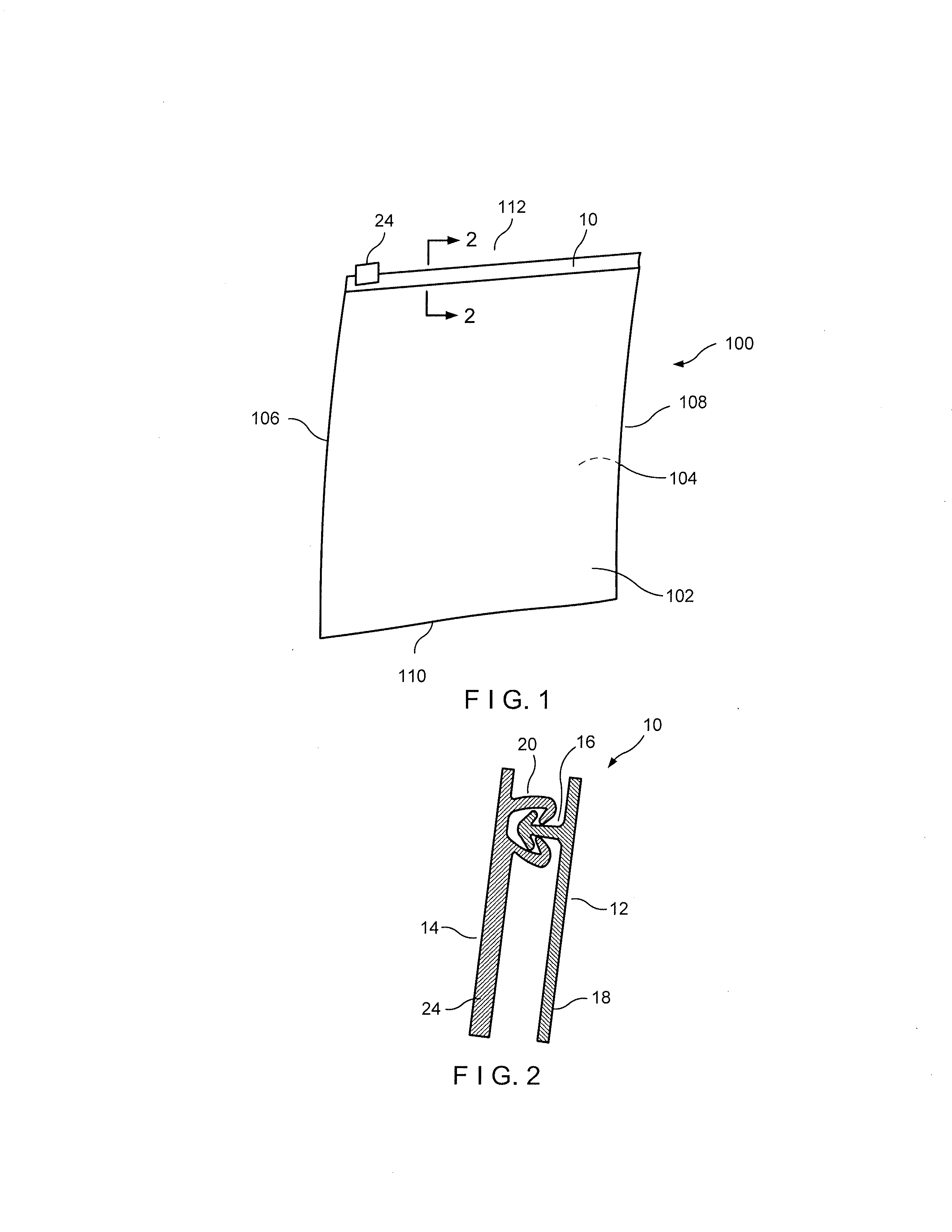

[0012]Referring now to the drawings in detail wherein like numerals indicate like elements throughout the several views, one sees that FIG. 1 is a plan view of a typical reclosable package 100 with front and rear co-extensive walls 102, 104 which are joined to each other by side seals 106, 108, and bottom seal 110 (which may be replaced by a fold if front and rear walls 102, 104 are implemented as a single sheet of polymeric material) thereby forming a mouth 112 which is made to be reclosable by zipper 10.

[0013]A typical embodiment of zipper 10 is shown in cross section in FIG. 2. This illustrated embodiment is meant only to be representative, in that a broad range of zipper designs is considered to be compatible with the present disclosure. Zipper 10 is typically made of polymeric material. Zipper 10 includes first and second profiles 12, 14, wherein first profile 12 includes a male interlocking element 16 and a first flange 18 while second profile 14 includes a female interlocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com