LED centralized DC power supply system and operating methods thereof

a power supply system and centralized technology, applied in the field of power supply systems, can solve the problems of difficult realization of unified light adjustment of a plurality of leds, large size and higher cost, and high cost and service life, and achieve the effect of less line loss, convenient maintenance of power supply, and effective control of line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The preferred embodiment of the invention is further described by combining the drawings and is in no way intended to limit the invention.

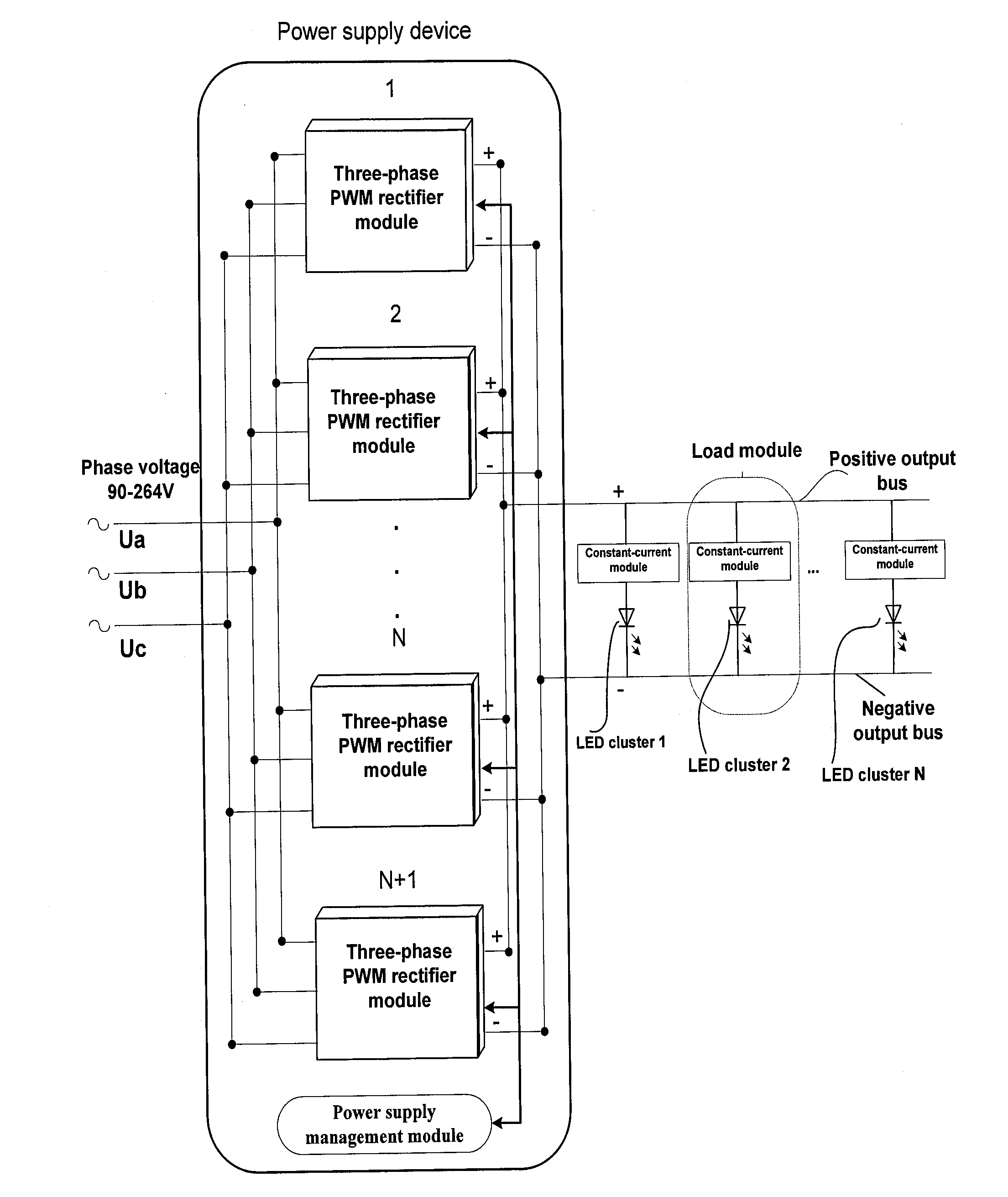

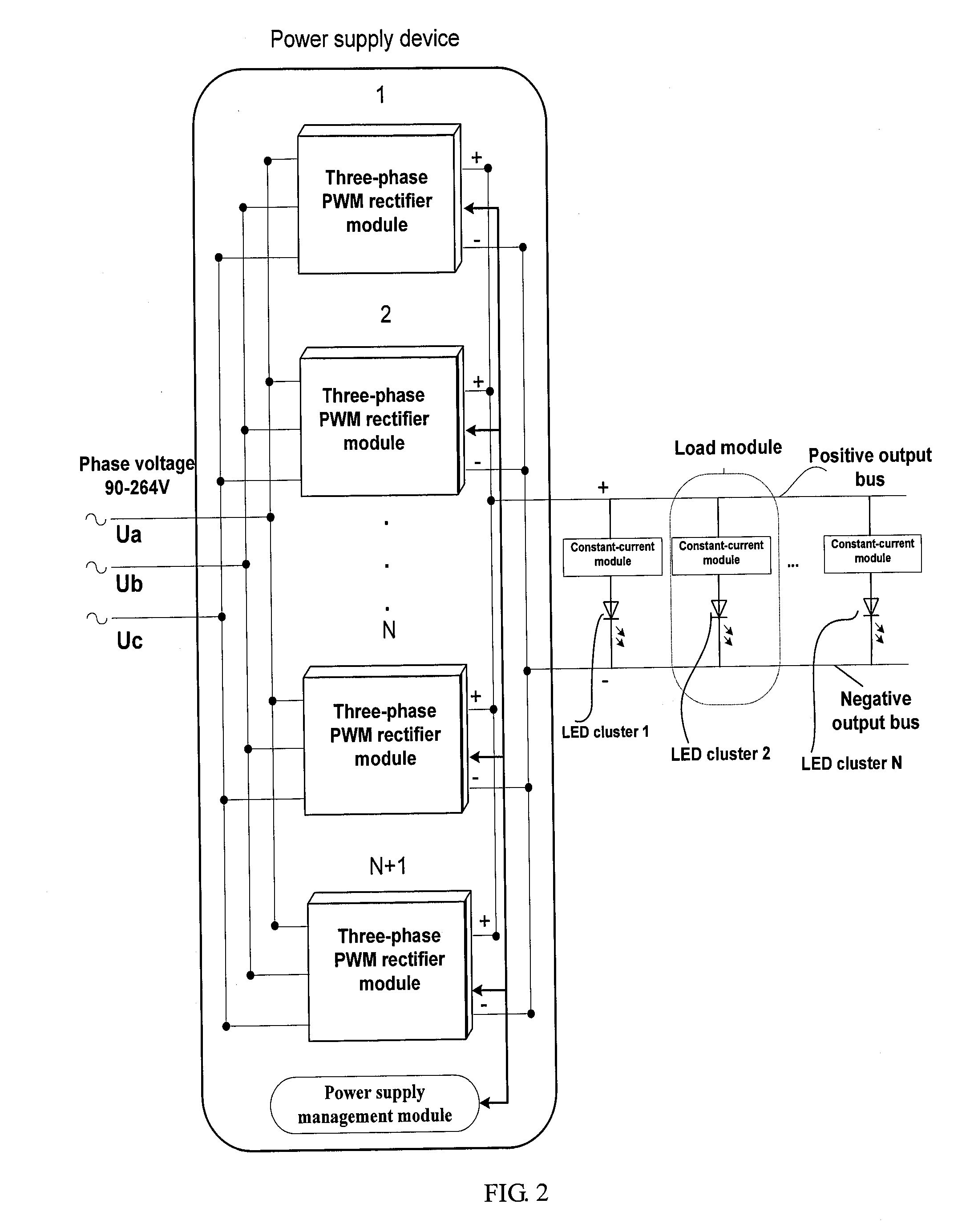

[0023]In FIG. 2, the invention provides an LED centralized DC power supply system, which comprises: a three-phase AC input interface; a power supply output interface having a positive output bus and a negative output bus; N+1 three-phase PWM rectifier modules, wherein each of N+1 three-phase PWM rectifier modules has a three-phase AC input end that is connected with said three-phase AC input interface, has a positive output end that is connected with said positive output bus, and has a negative output end that is connected with said negative output bus, wherein N is a natural number; LED cluster loads which are connected between said positive output bus and said negative output bus; and a power supply management module, connected with each of said N+1 three-phase PWM rectifier modules, detecting status of input and output of the power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com