Method of Packaging a Continuous Length of Product on a Spool using Indexed Layers

a technology of indexed layers and continuous lengths, which is applied in the directions of transportation and packaging, thin material processing, filament handling, etc., can solve the problems of space-consuming packaging, inconvenient shipping, and difficult to disperse by the end-user, so as to reduce the set-up time, minimize the interruption of the production line, and prolong the duration of continuous feed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

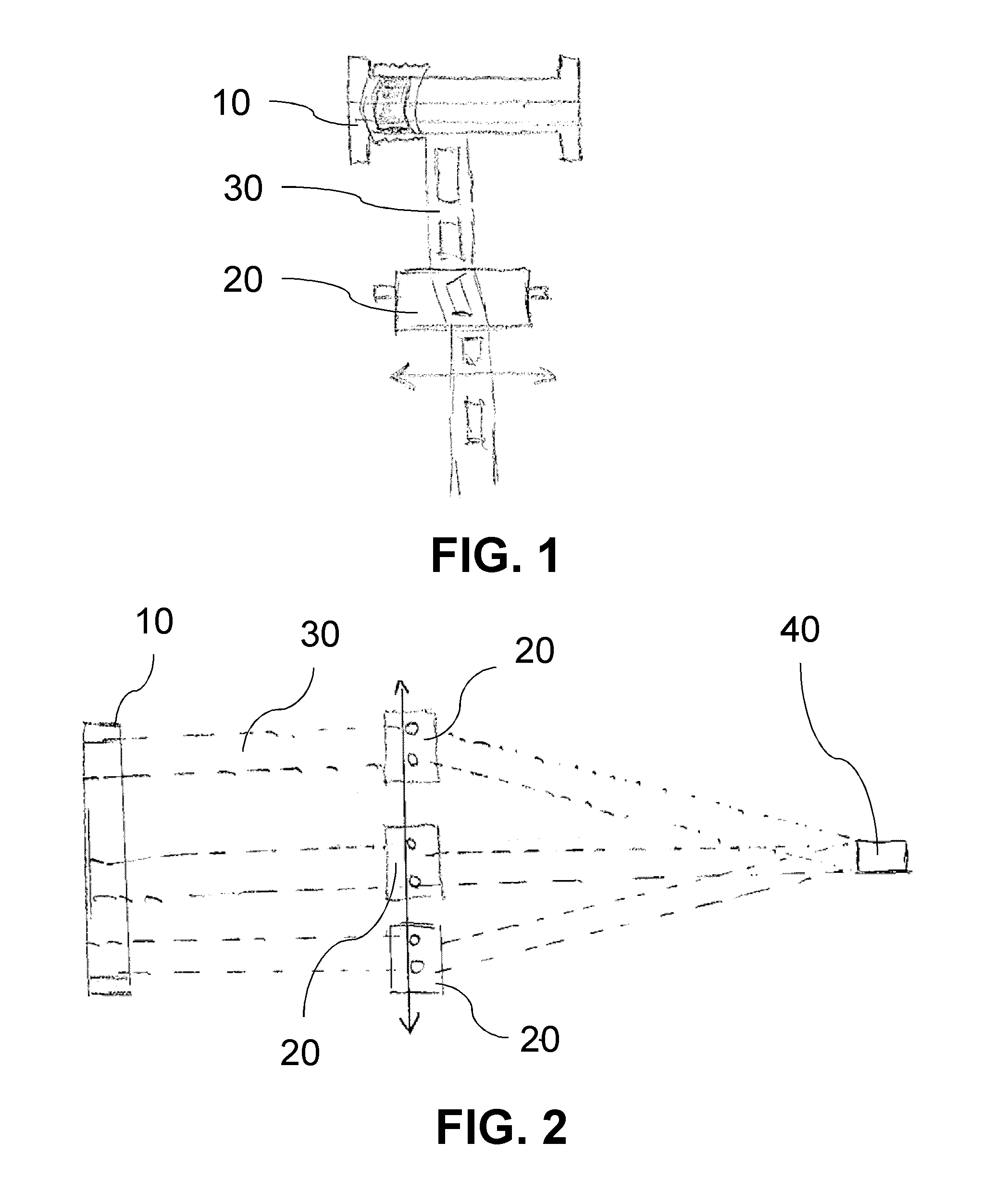

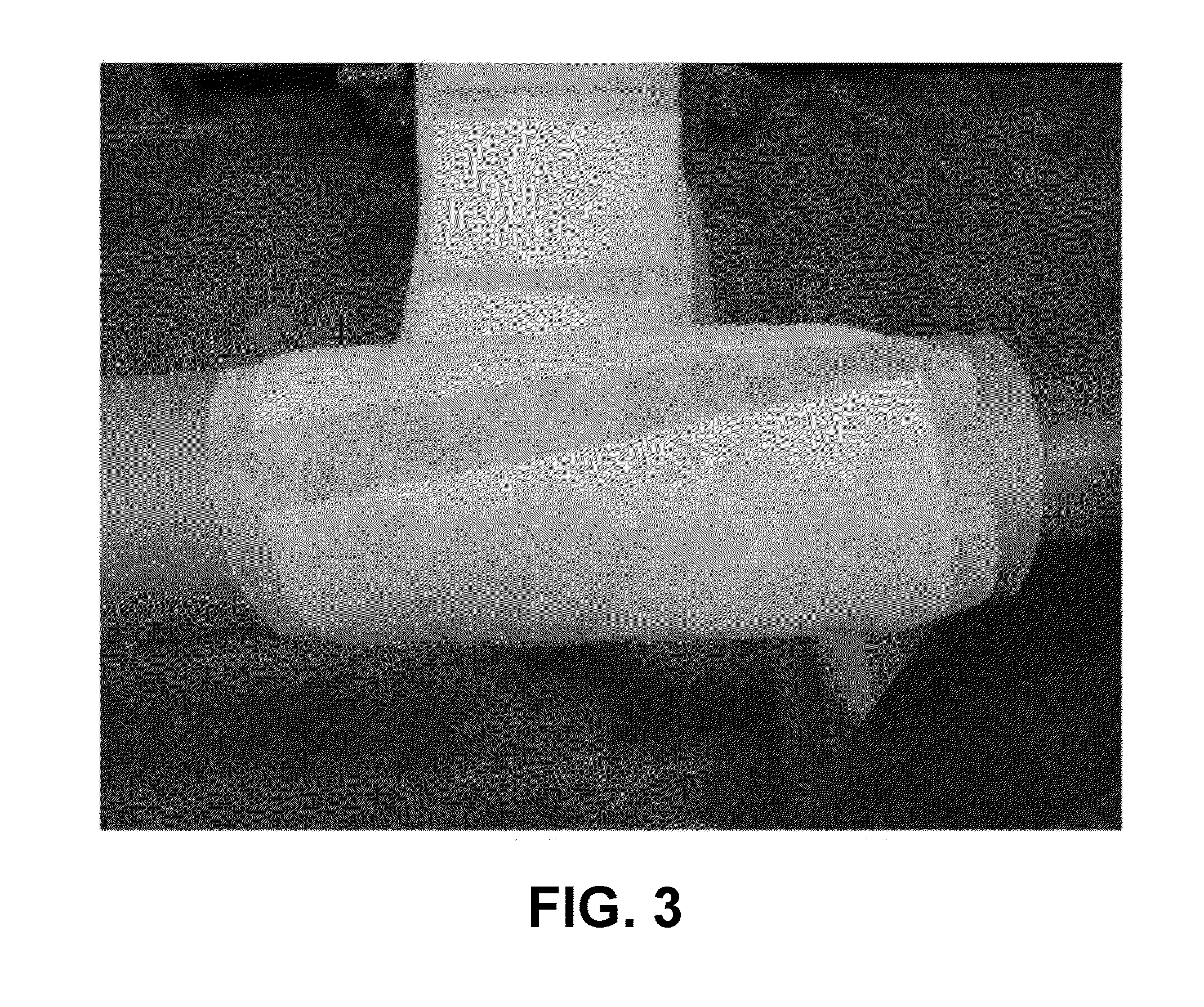

[0024]Referring to the figures, and in particular, FIGS. 1 to 6, there is provided a method for packaging a continuous thread of a material or a finished product onto a spool using rows of “indexed” layers of the material or finished product (herein referenced collectively as the “product”). Each layer of the product that is wrapped around the spool is slightly offset or shifted (i.e., “indexed”) a certain distance in relation to the previous layer of product, so as to partially, but not completely, overlap the previous layer. The indexed layer continues across an axial extent of the spool until it reaches one end of the spool to complete a first row of indexed layers, after which the direction of winding is reversed. The process continues in the opposite direction, until the other end is reached to complete a second row of indexed layers of the product. The direction of winding is reversed again, to wrap a third row of indexed layers across an axial extent of the spool in the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| index distance | aaaaa | aaaaa |

| index distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com