Machine-washable viscoelastic foam and devices made therefrom

a viscoelastic foam, machine-washable technology, applied in the field of polyurethane foams, can solve the problems that the devices made therefrom cannot be easily washed and dried, and achieve the effect of high airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

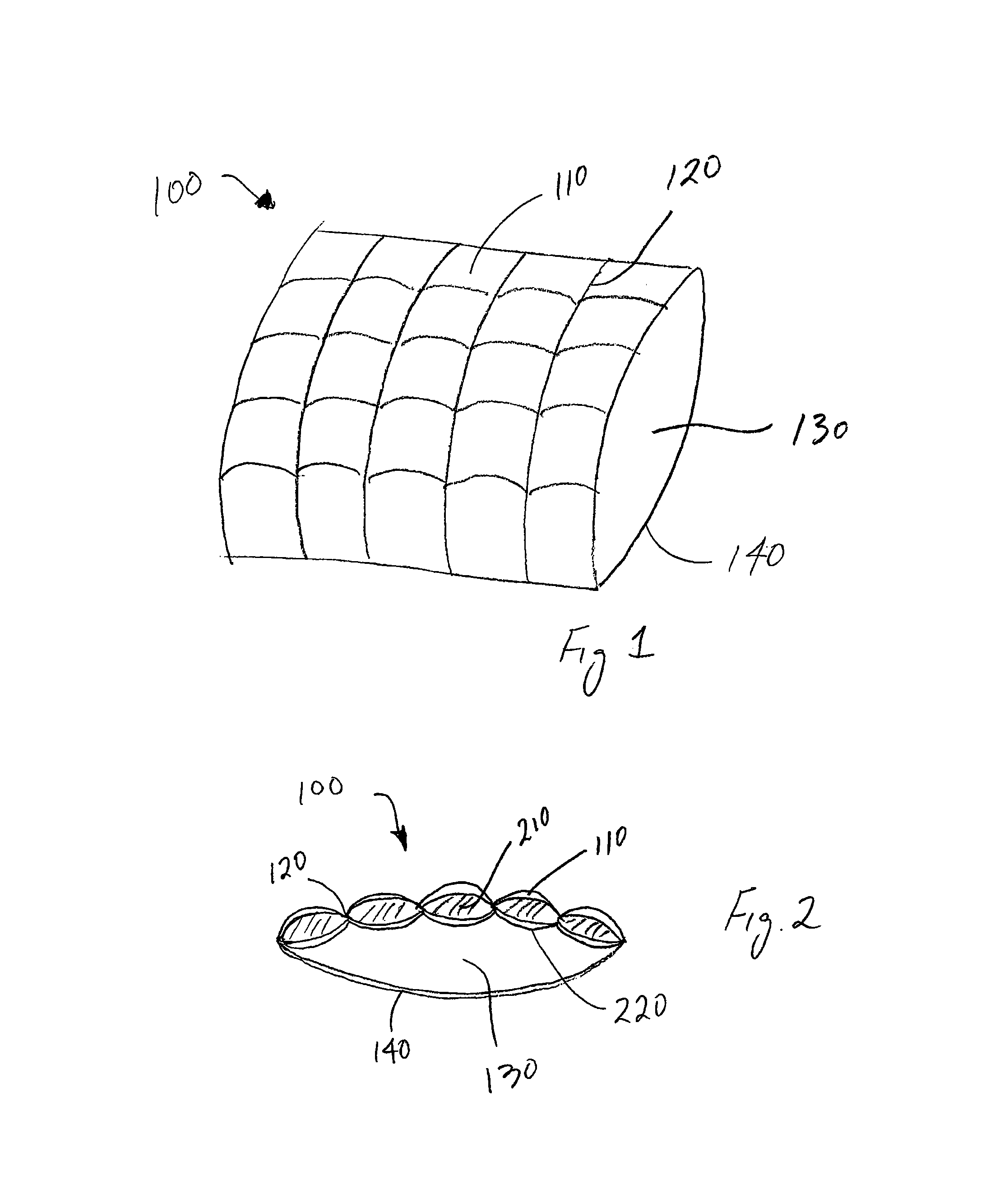

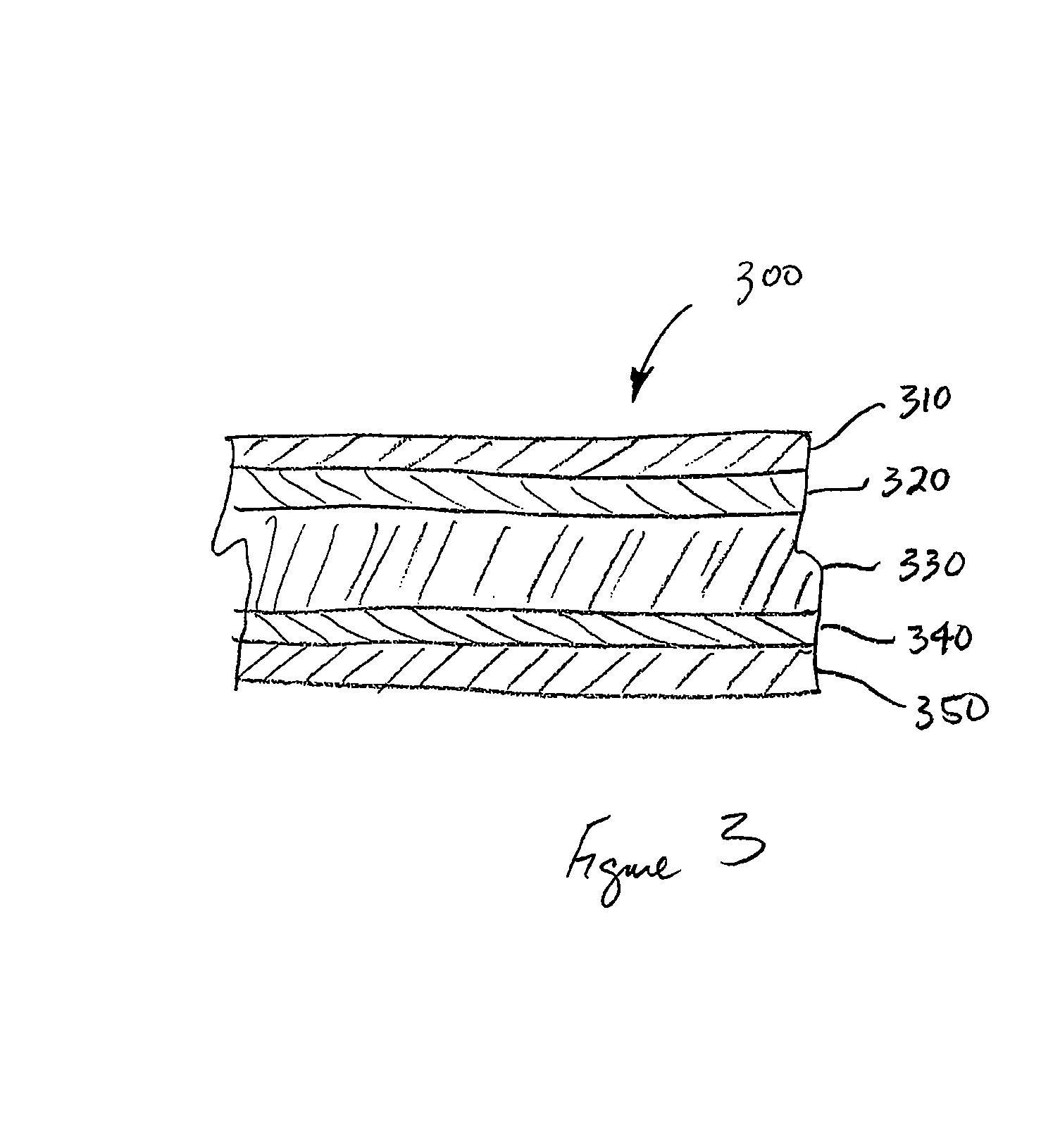

[0014]Embodiments presented herein provide a machine-washable cushioning device which includes a polyurethane viscoelastic foam. As used herein, machine-washable means capable of being laundered using a washing and drying cycle of a typical washing machine and drying machine. In order to be machine-washable, the viscoelastic foam may generally have low density, low thickness, and high airflow. Low density includes densities of about 1-4 lb / ft3; preferably about 1-3 lb / ft3. Low thickness includes thicknesses of about 0.25 cm to 2.5 cm; preferably about 0.5 cm to 1.5 cm. The foam may also include an indentation load deflection (“ILD”) rating of about 3-12 lbs.; preferably about 7-9 lbs; and more preferably about 6-8 lbs. Further, the foam may have a high airflow value of about 30 to about 110. The viscoelastic foam may further have a recovery time of 3-7 seconds.

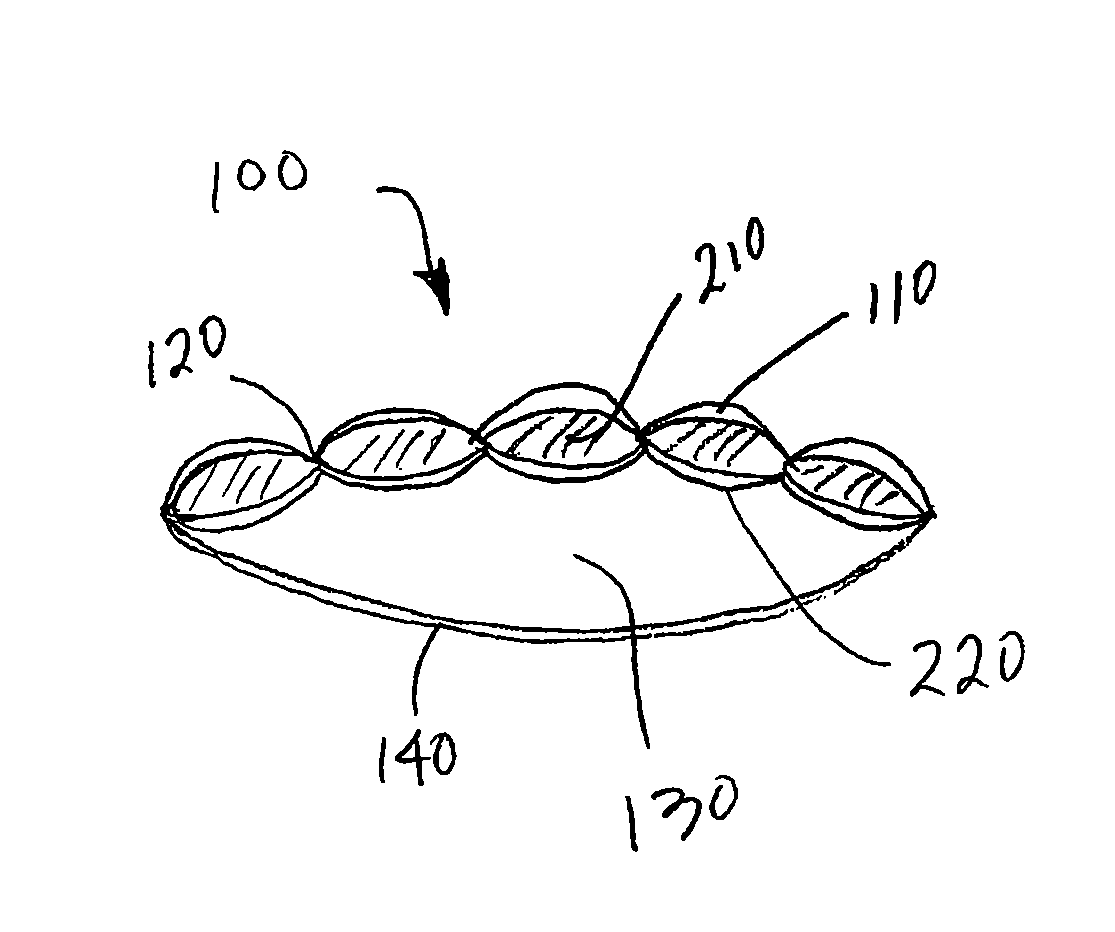

[0015]In some embodiments, the viscoelastic foam is quilted in the cushioning device, thereby preventing the viscoelastic fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diagonal length | aaaaa | aaaaa |

| diagonal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com