Compressed gas supply unit, compressed gas supply apparatus and control method of said unit and said apparatus

a technology of compressed gas and compressor, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of system security problems, system requirements for network line construction costs, and inability to accurately calculate the surplus of compressors, etc., to accurately grasp the abnormality of compressors, accurately determine the presence or absence of compressor abnormalities, and accurately determine the effect of compressor abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

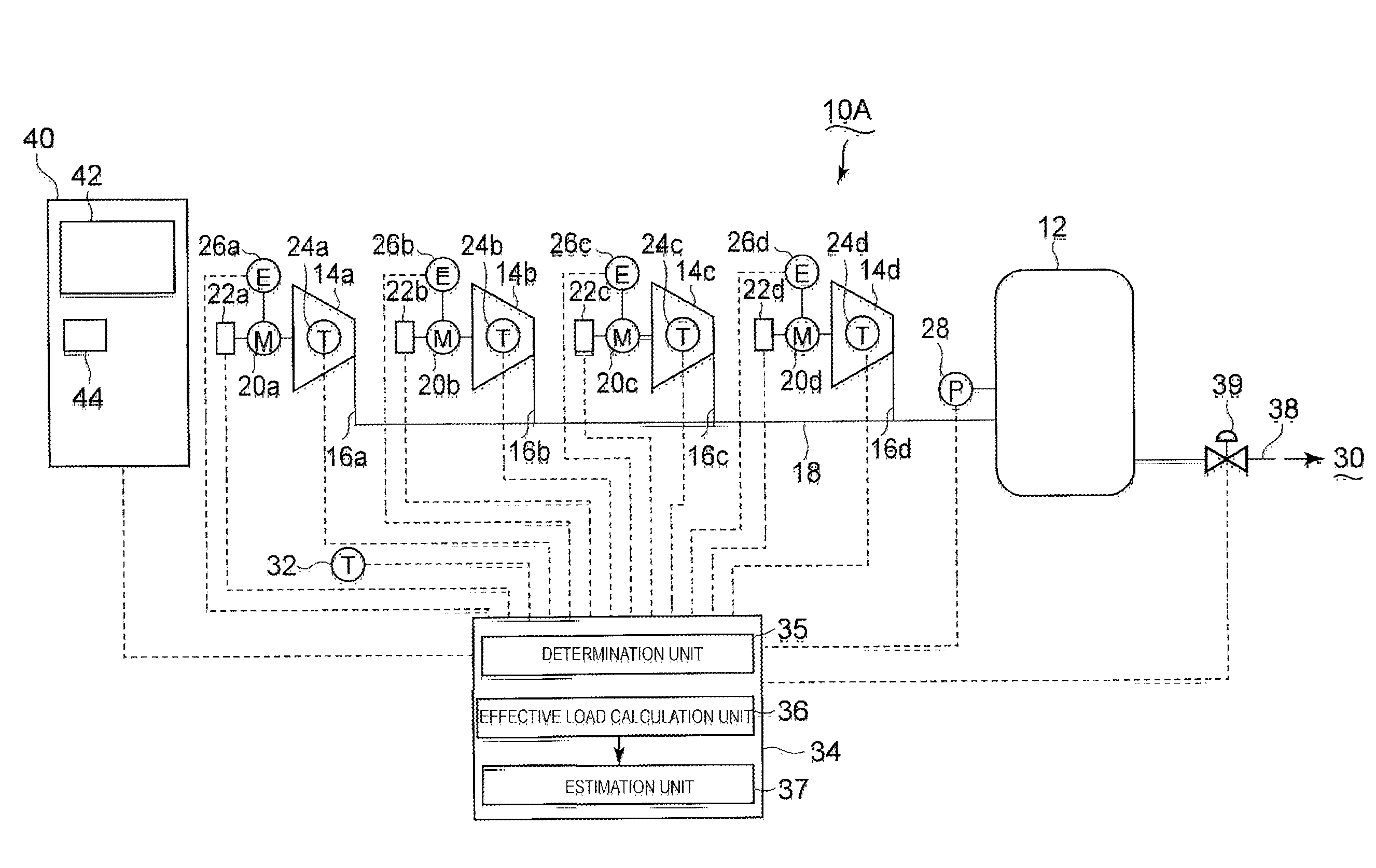

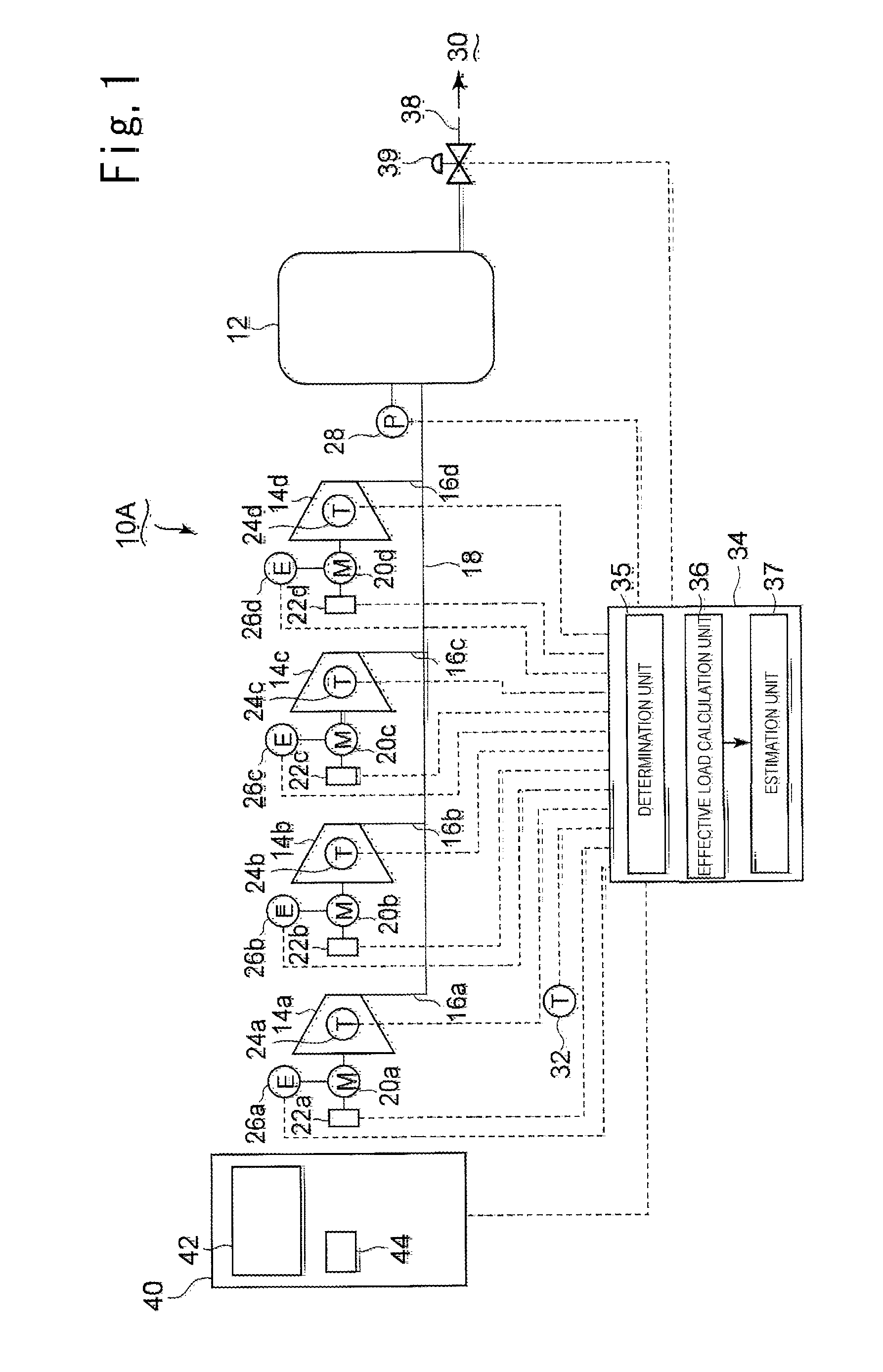

[0040]A first embodiment of each of an apparatus of a first aspect of the present invention and a method of a first aspect of the present invention will be described with reference to FIGS. 1 and 2. A compressed gas supply unit 10A of the present embodiment includes one storage tank 12 and four compressors 14a to 14d. Discharge paths 16a to 16d of the individual compressors are connected to a main supply pipe 18, and the main supply pipe 18 is connected to the storage tank 12. Gas discharged from each compressor flows through the main supply pipe 18 and is stored in the storage tank 12.

[0041]The individual compressors are provided with drive motors 20a to 20d and inverters 22a to 22d which can control the RPMs of the drive motors steplessly. With this, the RPMs of the individual motors can be individually controlled. Temperature sensors 24a to 24d which detect the temperatures of compressed gas are provided on the partitions of compression chambers of the individual compressors. The...

second embodiment

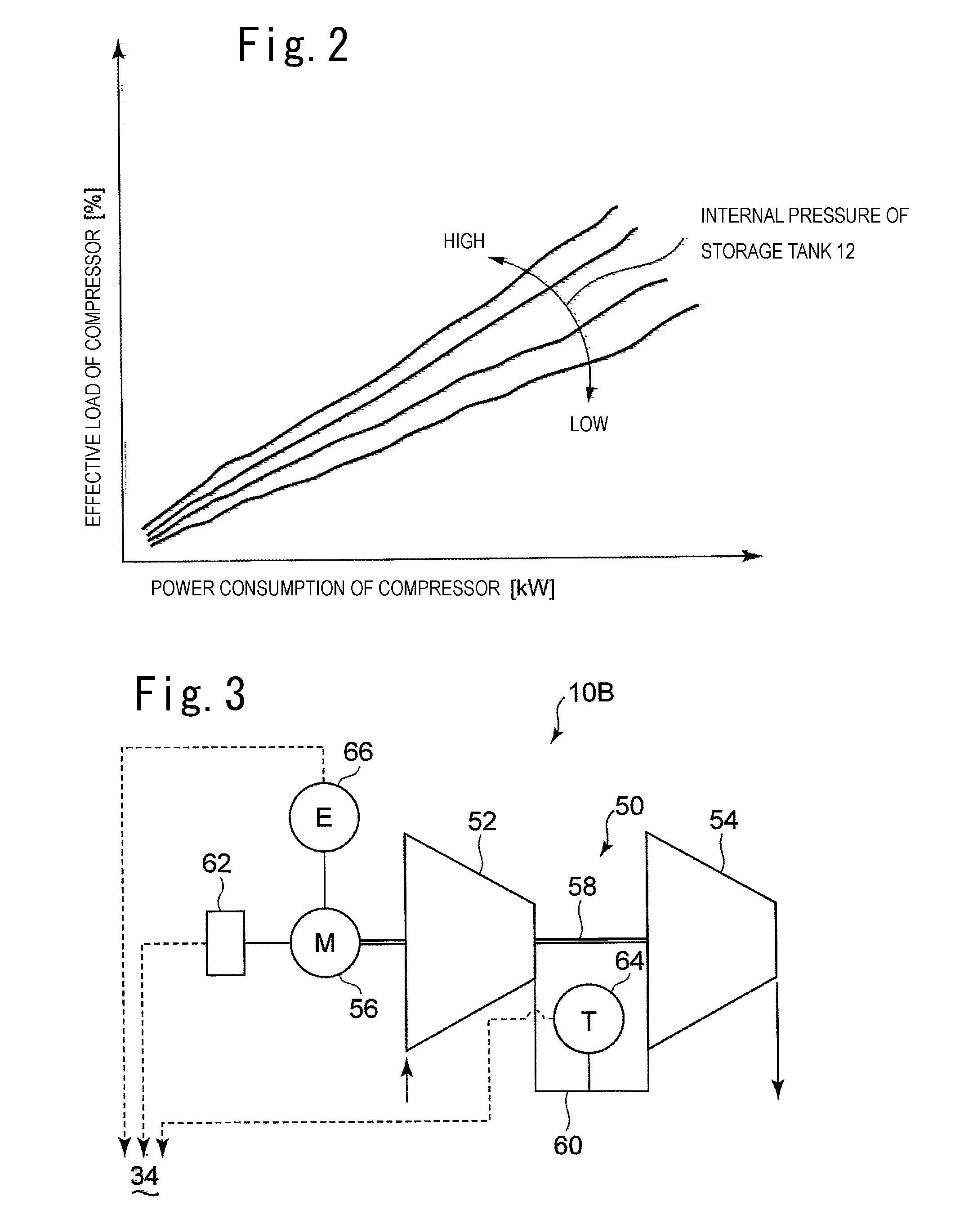

[0052]Next, a second embodiment of each of the apparatus of the first aspect of the present invention and the method of the first aspect of the present invention will be described with reference to FIG. 3. A two-stage compressor 50 constituting a compressed gas supply unit 10B of the present embodiment includes a low-pressure side compressor 52 and a high-pressure side compressor 54. That is, the low-pressure side compressor 52 and the high-pressure side compressor 54 are driven by a shared rotating shaft 58, and the rotating shaft 58 is driven by a drive motor 56. Gas discharged from the low-pressure side compressor 52 is supplied to the high-pressure side compressor 54 via an intermediate discharge path 60, further compressed in the high-pressure side compressor 54, and sent to the storage tank (not shown). The RPM of the drive motor 56 can be steplessly adjusted by an inverter 62.

[0053]The intermediate discharge path 60 is provided with a temperature sensor 64 which detects the t...

third embodiment

[0056]Next, an embodiment of each of an apparatus of a second aspect of the present invention and a method of a second aspect of the present invention will be described with reference to FIG. 4. A compressed gas supply apparatus 70 of the present embodiment includes a plurality of compressed gas supply units 10A, 10B, and 10C provided at positions apart from each other and a central control unit 72 which can remotely control the compressed gas supply units. Each of the compressed gas supply units 10A and 10C has the same configuration as that of the compressed gas supply unit 10A of the first embodiment, and the compressed gas supply unit 10B has the same configuration as that of the compressed gas supply unit 10B of the second embodiment.

[0057]The compressed gas supply unit 10A and the central control unit 72 are provided with transmitter-receivers 74 and 80 respectively. The compressed gas supply unit 10A and the central control unit 72 can perform data communication therebetween ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com