Zipper Type Liquid Crystal Module Packaging Bag and Method for Packaging Liquid Crystal Module with Same

a liquid crystal module and packaging bag technology, applied in the field of packaging bags for liquid crystal modules, can solve the problems of inconvenient reverse process, high cost, and inability to meet the requirements of continuous use, and achieve the effects of convenient packaging and access of liquid crystal modules, excellent protection, and repeatable us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]To further expound the technical solution adopted in the present invention and the advantages thereof, a detailed description is given to a preferred embodiment of the present invention and the attached drawings.

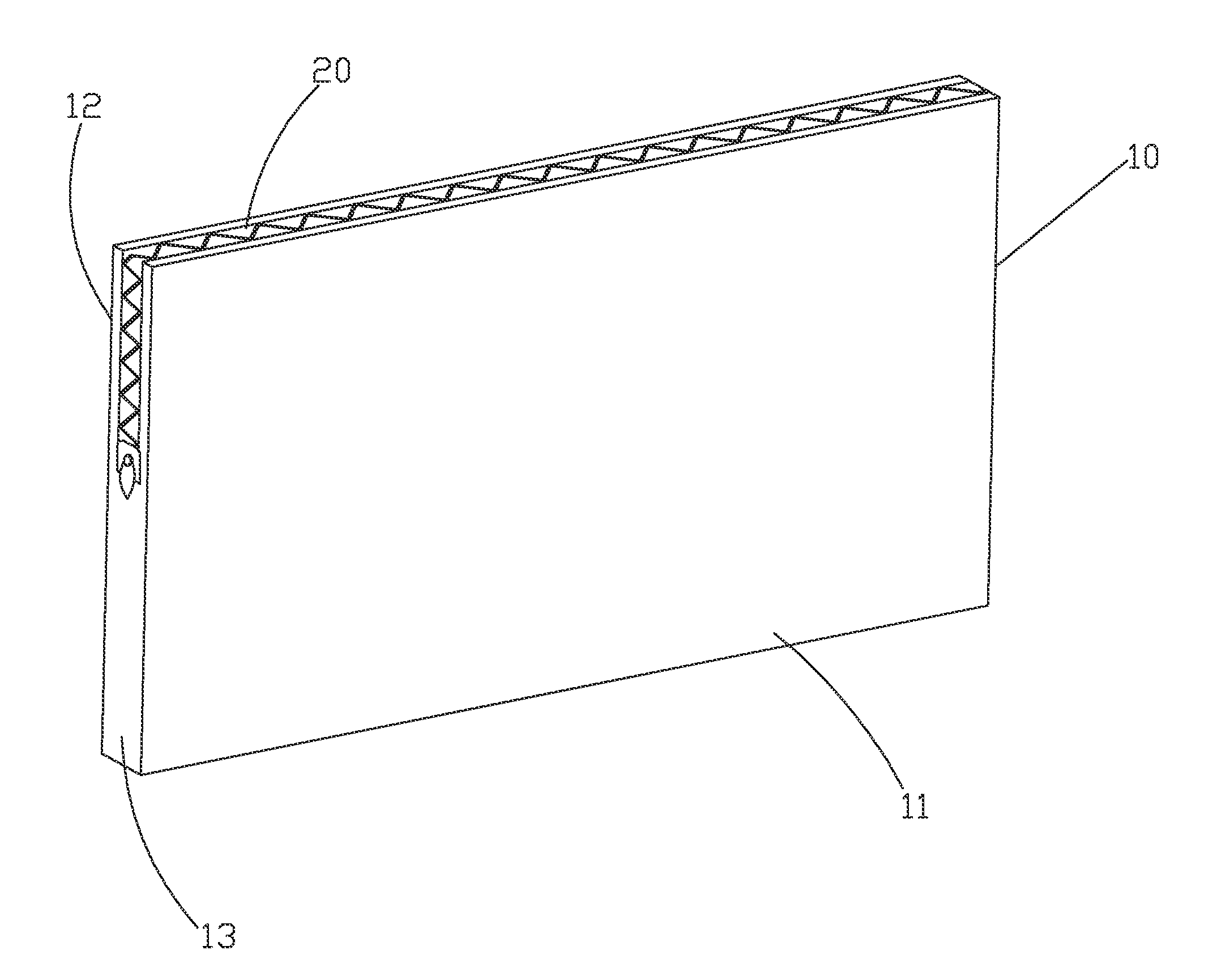

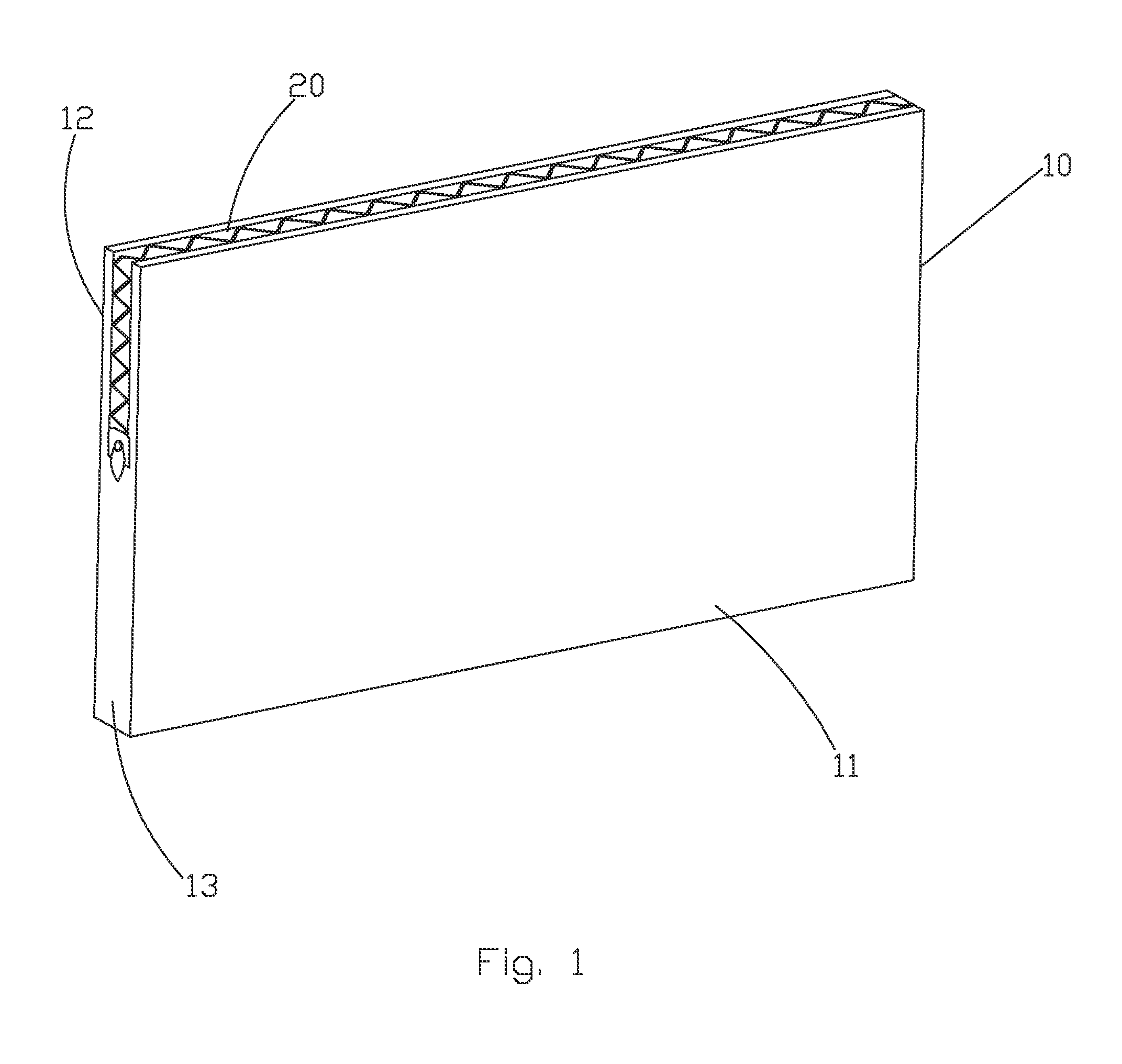

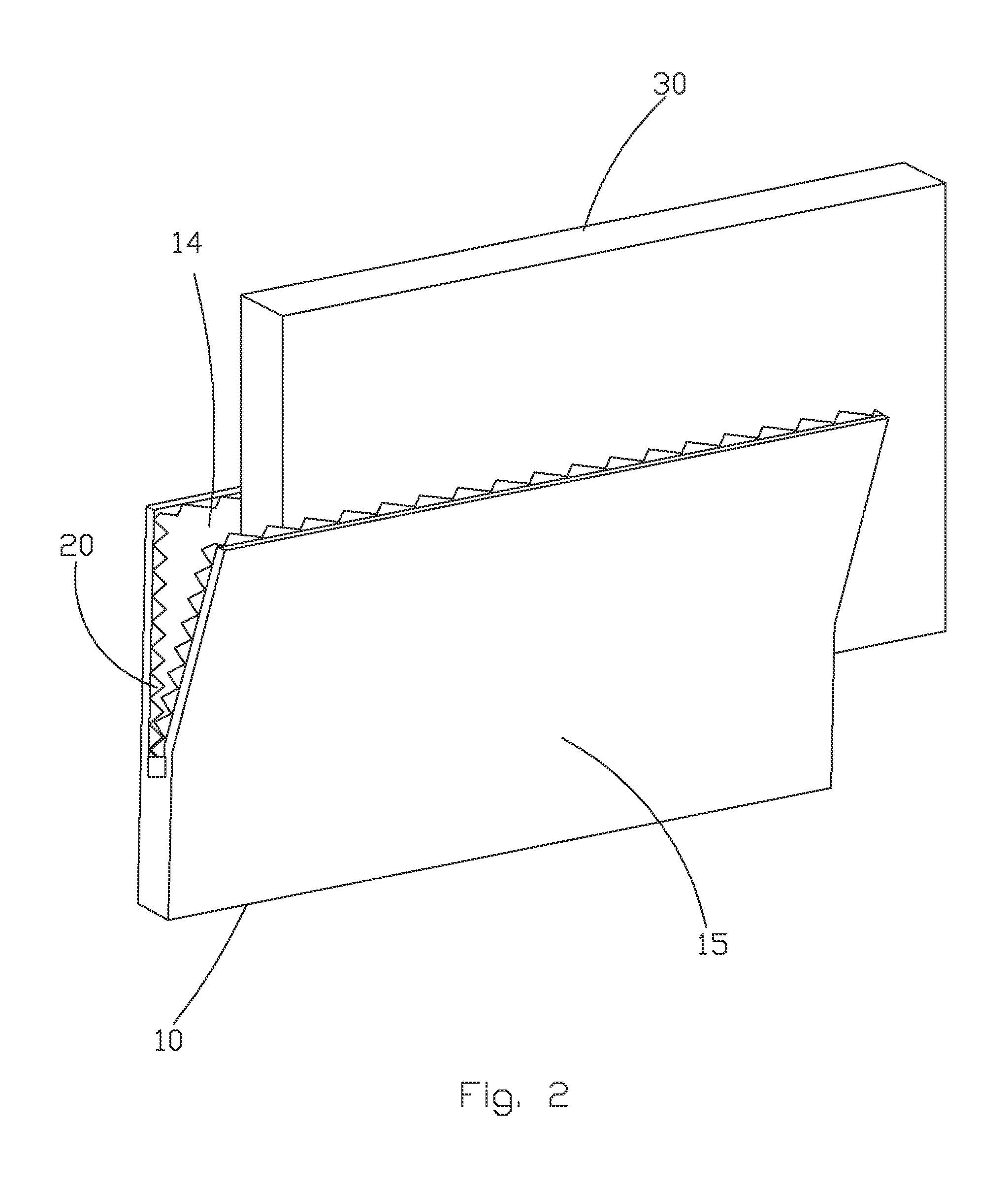

[0028]Referring to FIGS. 1 and 2, the present invention provides a zipper type liquid crystal module packaging bag. The zipper type liquid crystal module packaging bag comprises a bag body 10 and a zipper 20 mounted to the bag body 10. The bag body 10 is provided for receiving and retaining a liquid crystal module 30. The bag body 10 has an outer circumference that is shaped to correspond to an outer circumferential shape of the liquid crystal module 30 to be packaged. The arrangement of the zipper 20 allows easy and efficient deposition and removal of the liquid crystal module 30 into and out of the bag body 10.

[0029]The bag body 10 forms an opening (not labeled) for receiving entry of the liquid crystal module 30 into the bag body 10. The zipper 20 is mounted to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| circumferential shape | aaaaa | aaaaa |

| soft | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com