Chromatography column support

a technology for chromatography columns and supports, applied in the direction of machine supports, instruments, separation processes, etc., can solve the problem of complex design of large-scale preparative chromatographic processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

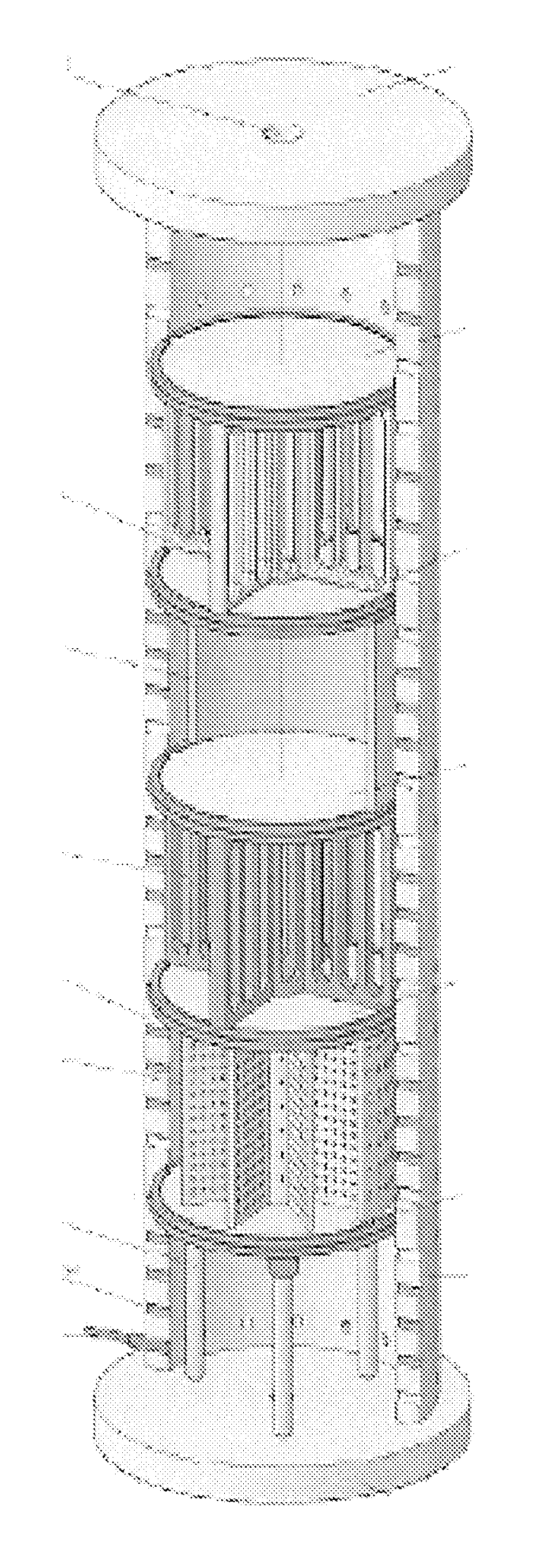

Packing of a Chromatography Column Comprising a Support as Reported Herein

[0213]During the packing process of columns which are equipped with the flexible bed support elements as reported herein the homogeneous inserting and distribution of the chromatography medium is very important. There are two possibilities to reach a homogeneous packing. The first is to put the flexible bed support element in the column first and inserting the slurry afterwards. In this case the slurry must homogeneously be brought in into the column. The other possibility is bringing in the slurry into the column first, homogenizing it in the column and afterwards introducing the bed support element by putting it directly into the slurry in the column. During the settling a homogeneous column bed forms and encloses the element. After the specified settling time can either an intermediate column fit be put on the bed support element or the column can be locked with an adapter. If an intermediate column frit is...

example 2

Chromatographic Separation Using a Conventional Chromatography Column not Comprising a Support as Reported Herein—Cycle Number and Pressure Characteristics for the use of the Chromatography Material

[0214]Herein the life cycle of a conventionally packed HPLC column is shown. It can be seen from FIG. 7 that the pressure directly after packing is about 40 bars. This increases after the fortieth regeneration cycle to about 70 bars.

[0215]Packing details:[0216]Column diameter: 30 cm[0217]Column type: dynamic compression without bed support elements and intermediate column frits[0218]Bed height: about 40 cm[0219]Used chromatographic material: Vydac C4[0220]Flow rate: 162 l / h

[0221]Pressure values during the regenerations and cycle numbers are shown in FIG. 7.

example 3

Chromatographic Separation Using a Conventional Chromatography Column Comprising a Support as Reported Herein—Cycle Number and Pressure Characteristics for the use of the Chromatography Material

[0222]Herein is shown a HPLC column with a support as reported herein and an intermediate column frit. It can be seen that a lower initial pressure after packing compared to the column of Example 2 can be obtained. Altogether a more stable pressure course can be obtained over the use cycles. Also a maximum cycle number of 98 can be reached without the need to repack the column. The intermediate column frit without the support as reported herein fulfills a bed support function at the HPLC media which are compressible only in a very low measure.

[0223]Packing details:[0224]Column diameter: 15 cm[0225]Column type: dynamic compression with intermediate column frit[0226]Bed height: about 40 cm[0227]Used chromatographic material: Vydac C4[0228]Flow rate: 35 l / h

[0229]Pressure values during the regene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com