Apparatus and process for heat treating a packaged food product

a technology for packaging food products and apparatuses, which is applied in the direction of transportation and packaging, packaging, electric/magnetic/electromagnetic heating, etc., can solve the problems of not efficiently integrating energy into the system, and many prior art systems are not able to (efficiently) heat treat packaged food products, so as to achieve efficient energy and energy efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

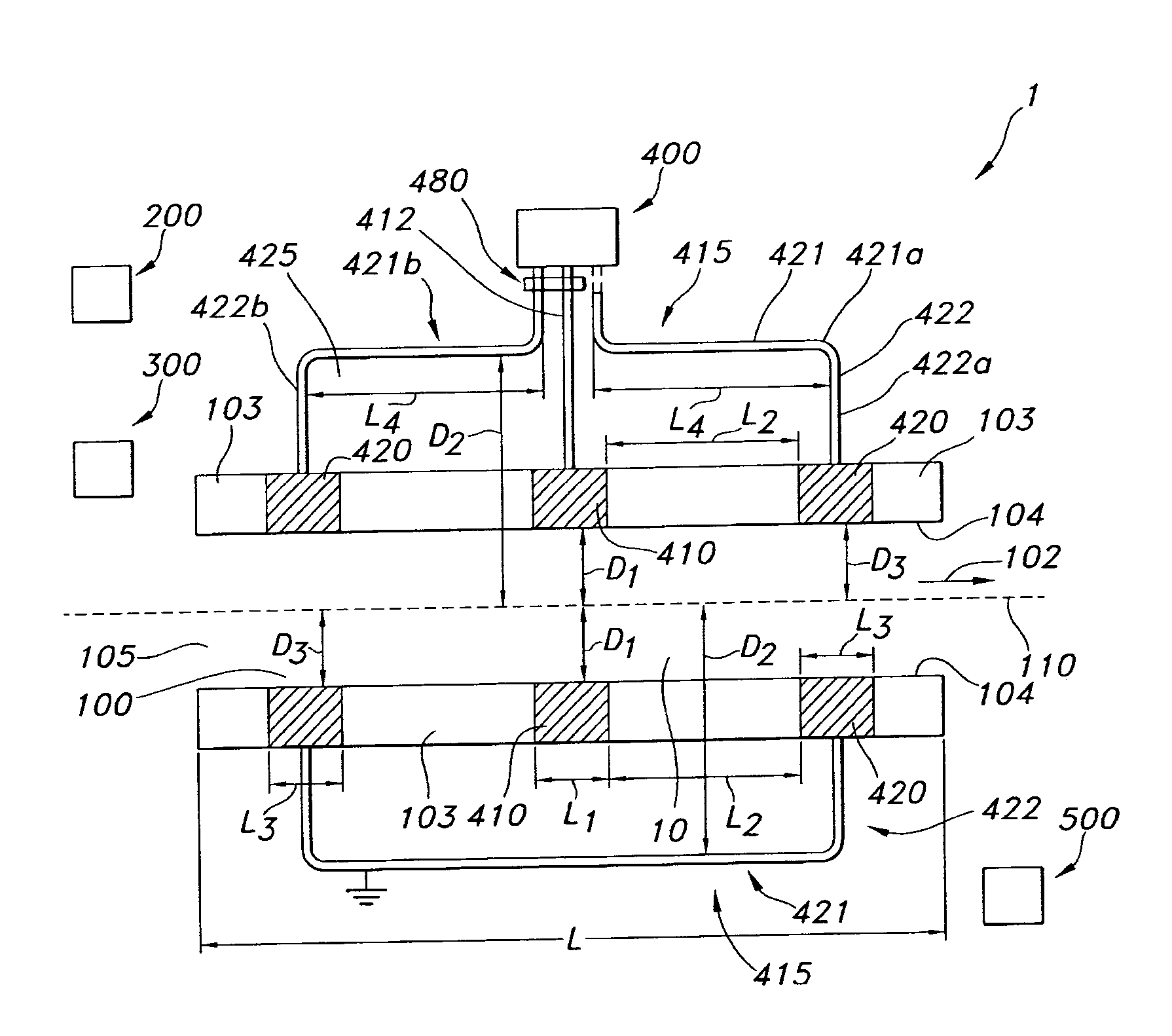

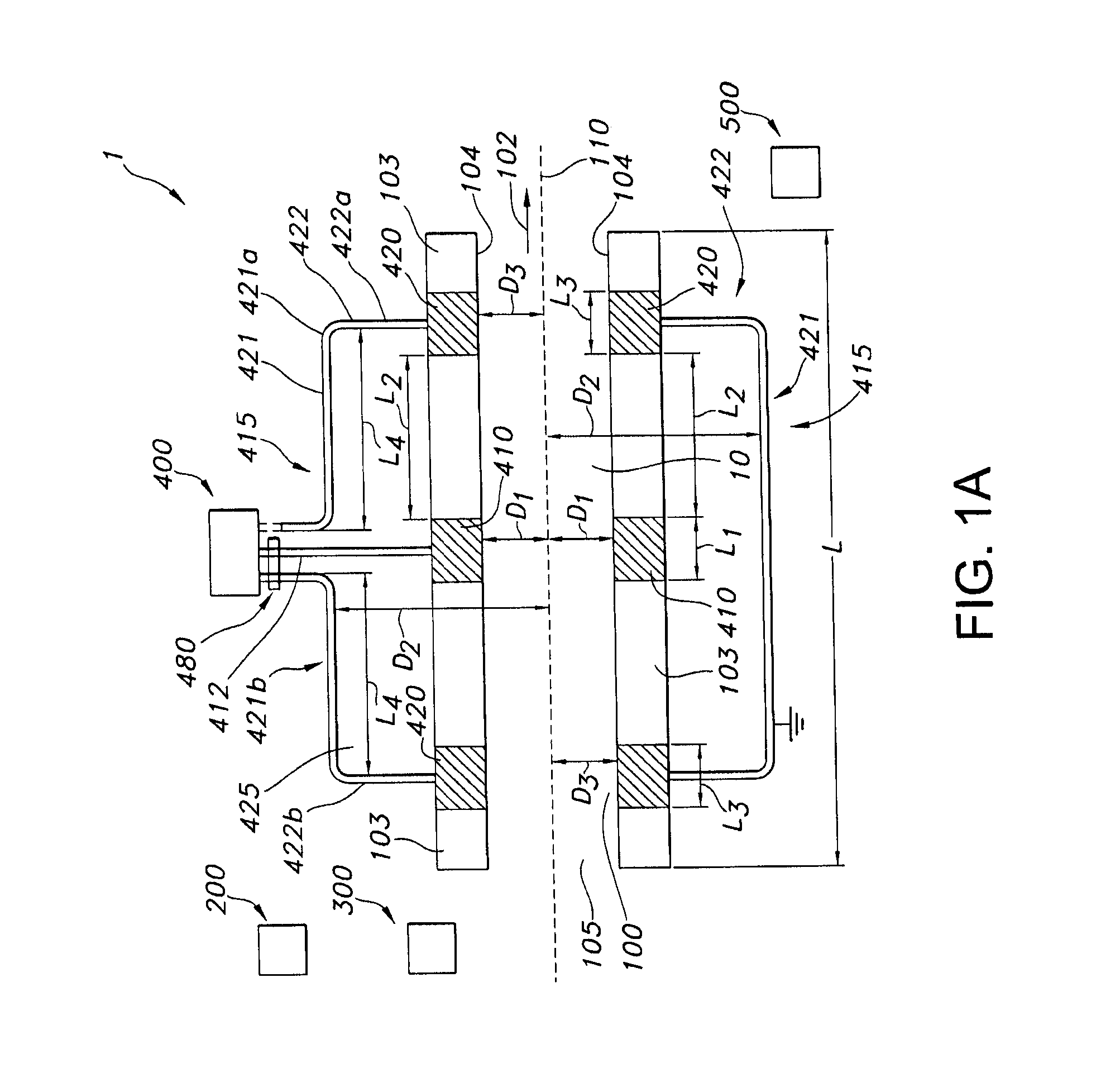

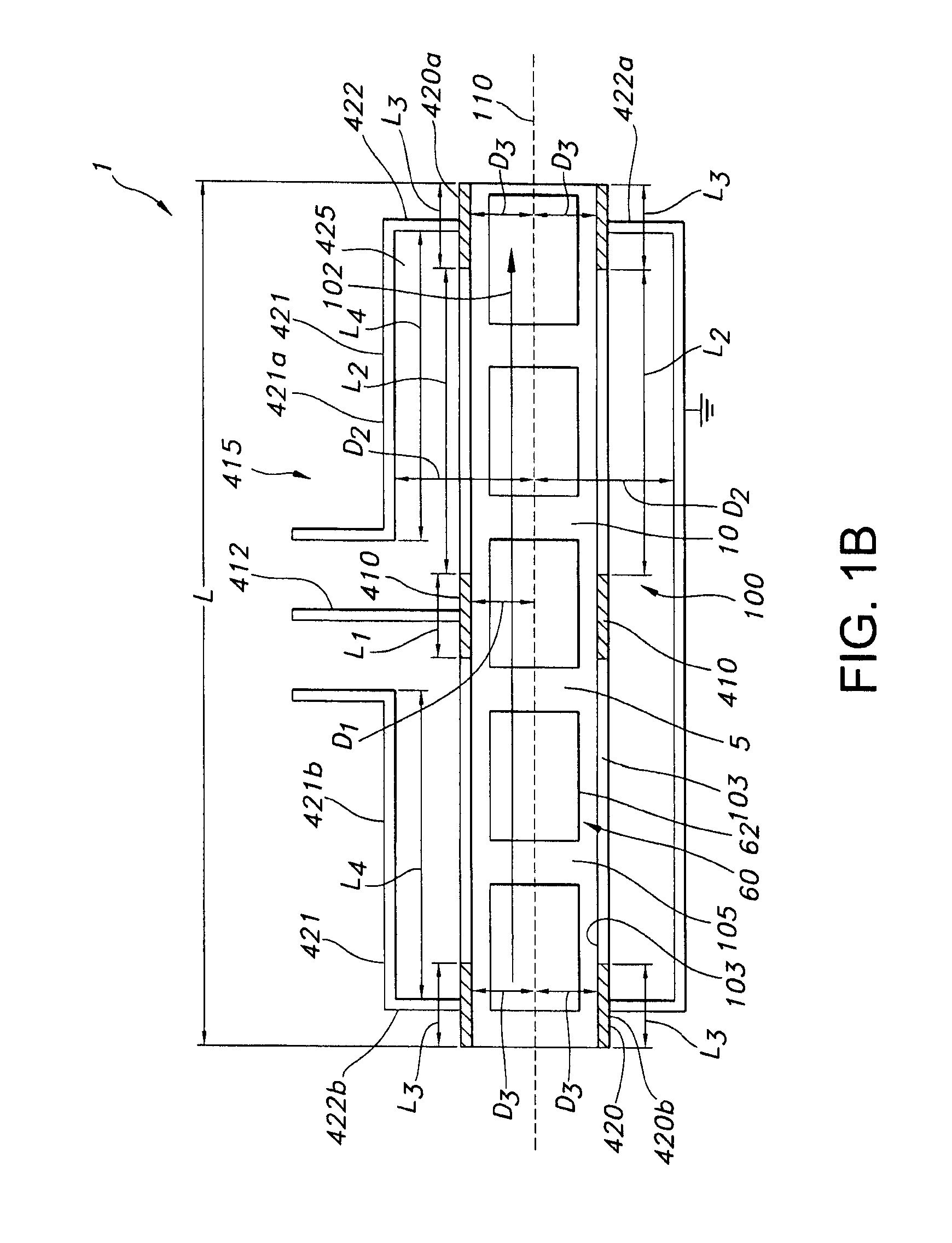

[0064]FIG. 1a schematically depicts an embodiment of the apparatus, indicated with reference 1 for heat treating a packaged food product (not depicted, however see amongst others FIGS. 1b-1c) in e.g. a continuous packaged food heat treating process. The apparatus 1 comprises a channel 100 with a channel length L, a channel axis 110 and a channel wall 103 (of insulating material, except where the electrodes are; see also below). The channel wall 103 surrounds a channel interior 105. Here, the channel interior is empty, but during processing, the channel interior 105 will be in general be filled with (pressurized) liquid (such as de-ionized a water). The apparatus also comprises a pressurizer (schematically depicted) configured to control the pressure of the liquid (not depicted, however see amongst others FIGS. 1b-1c) within the channel 100. Further, the apparatus comprises a transport unit 300 configured to transport the packaged food product in a propagation direction 102 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com