Economizer HVAC and control system

a control system and hvac technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., to achieve the effect of reducing the potential for termination errors, reducing technician effort, and simplifying the way the system is installed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

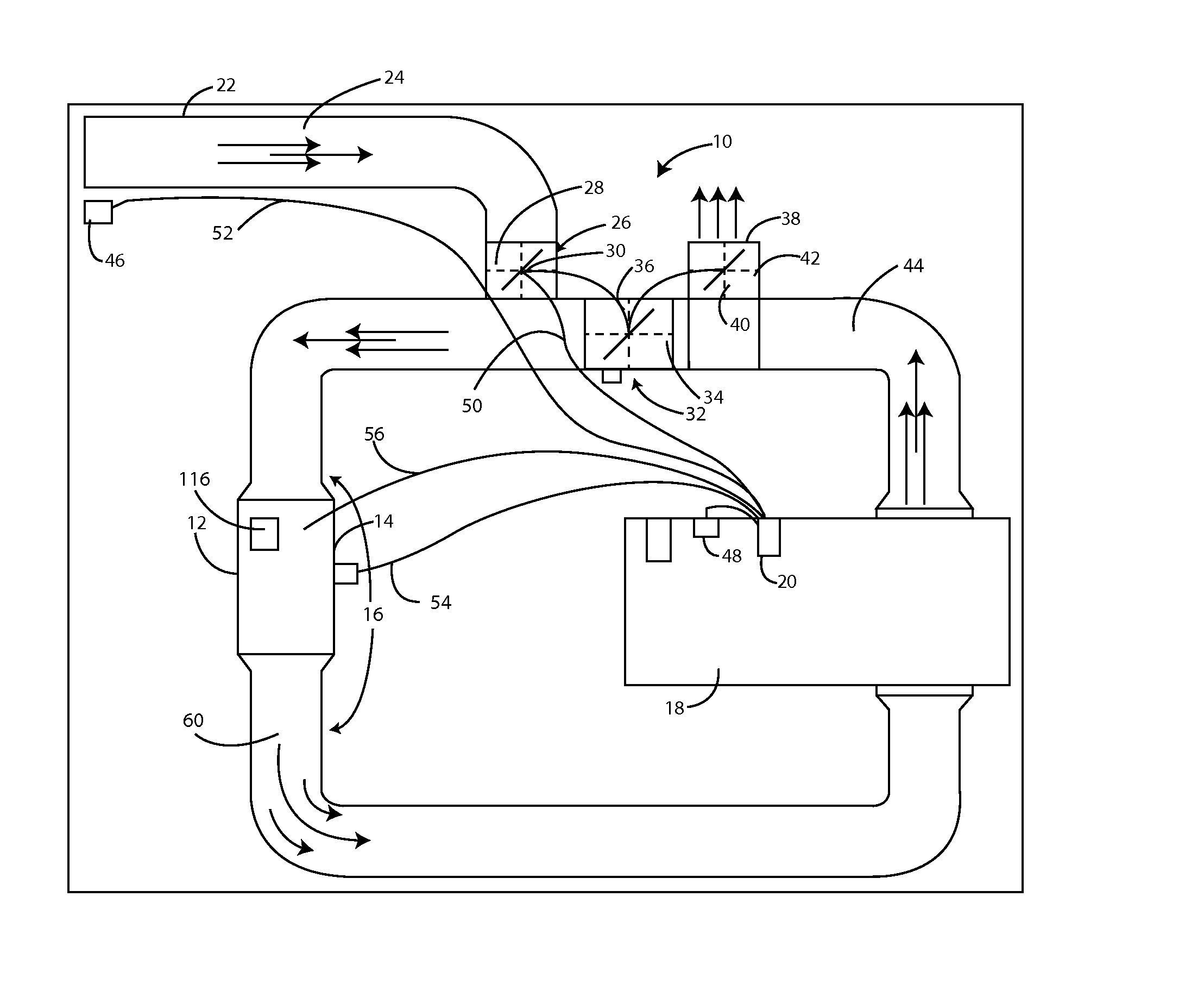

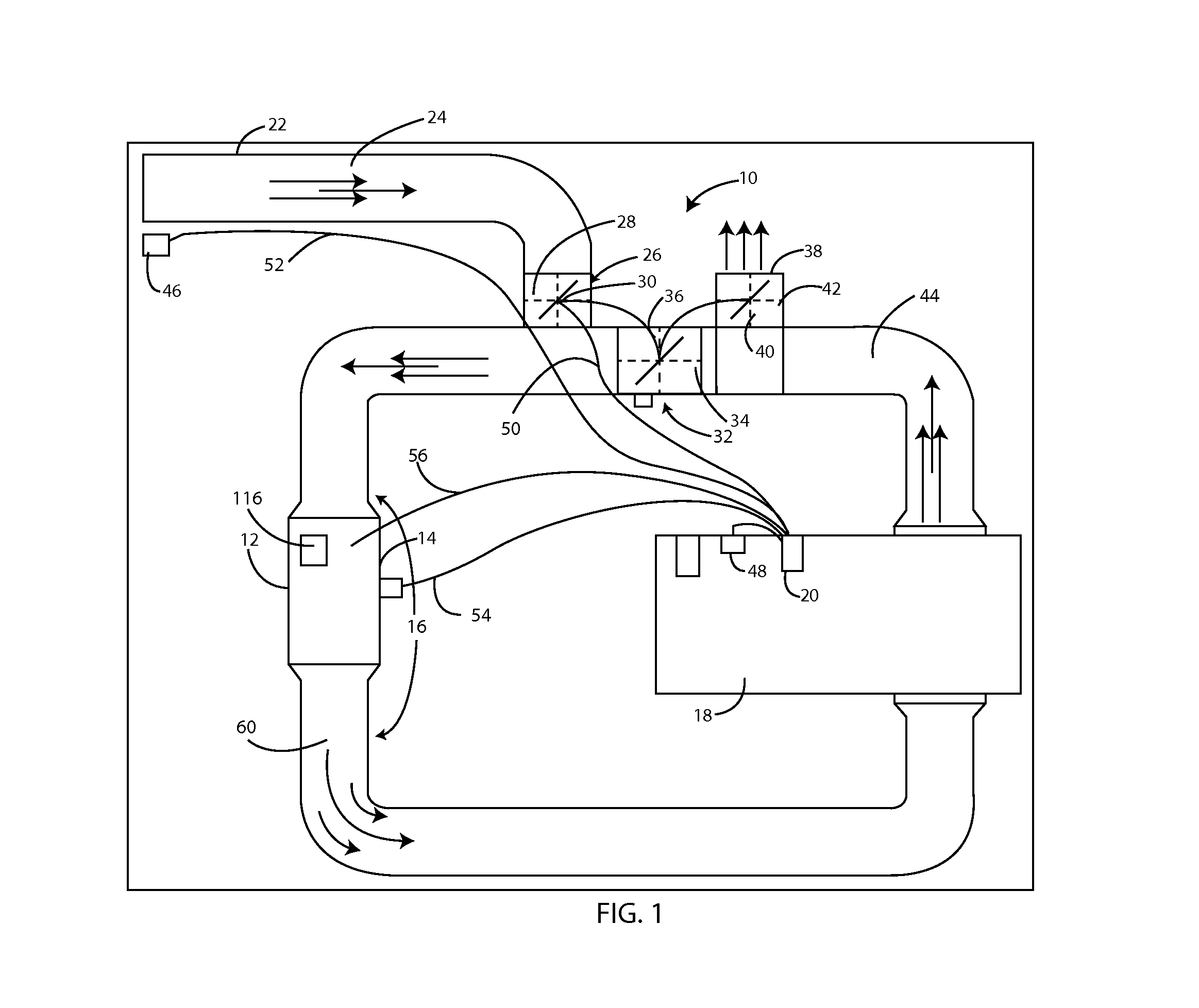

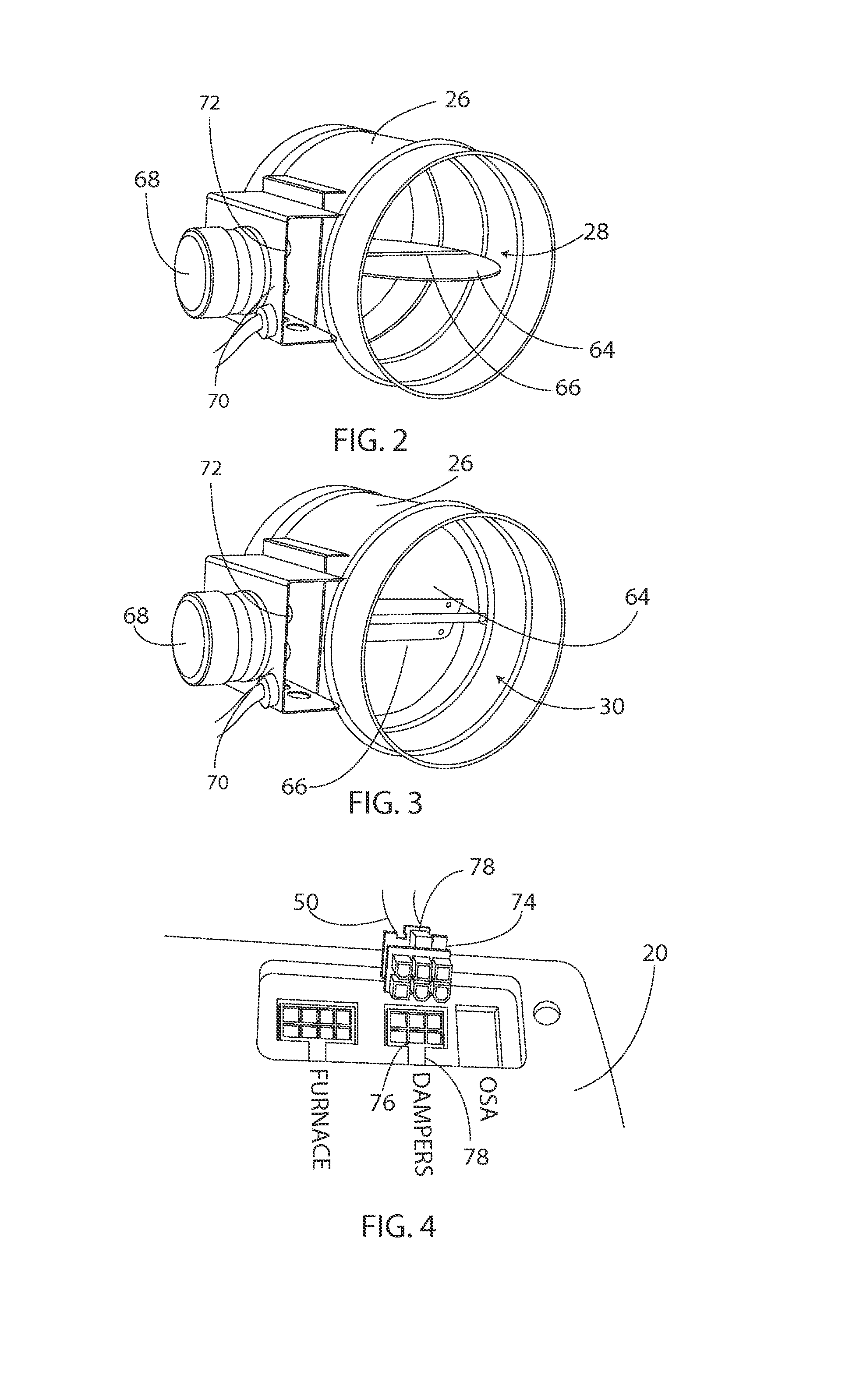

[0028]FIG. 1 shows the HVAC system of the disclosed technology, which provides for economizer mode operation of the HVAC system 10. The HVAC system 10 includes a circulation fan 12, cooling unit 14, and a network of air delivery ducts 16. The HVAC system 10 provides heating and cooling for a conditioned space 18. A user controls the economizing portion of the HVAC system 10 with control module 20. The HVAC system 10 includes an outside air intake duct 22 to provide outside airflow 24 to the conditioned space 18. Also included is a first, or intake, damper 26. The first damper 26 has two positions: a first, or closed, position 28, and a second, or open, position 30. The HVAC system 10 may have an isolation damper 32, operable between an open position 34 and a closed position 36, and a third (relief) damper 38, operable between a closed position 42 and an open position 40. A preferred embodiment of the control system and HVAC system uses three dampers. Both the second (isolation) damp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com