Oil premix burner

a technology of oil premix burner and oil premix, which is applied in the direction of burners, indirect carbon-dioxide mitigation, combustion types, etc., can solve the problems of relatively large overall combustion chamber compared to known designs, difficult heating of air, etc., and achieves the effect of improving combustion quality and robustness, improving the energy balance of the burner, and increasing the burner surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

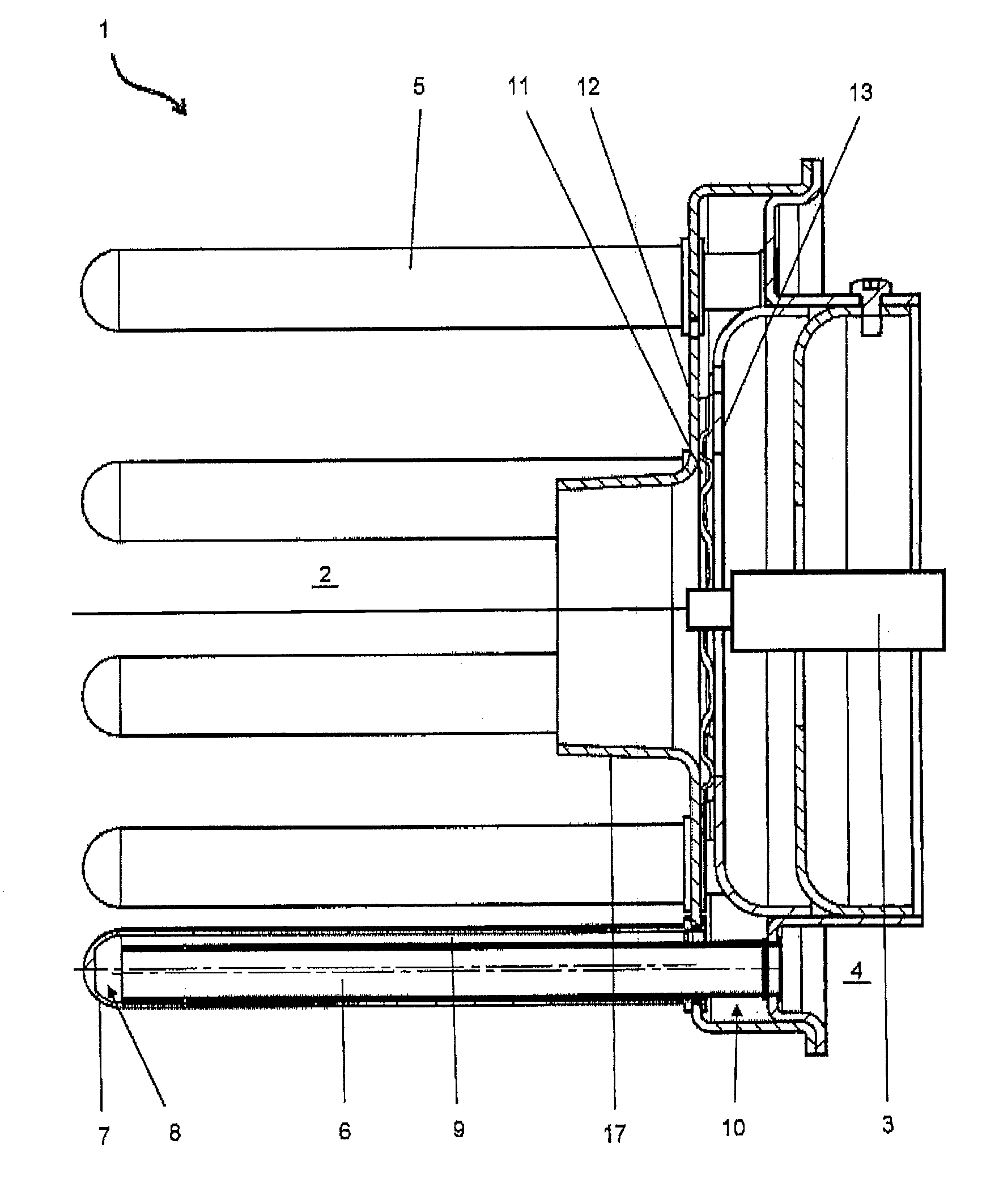

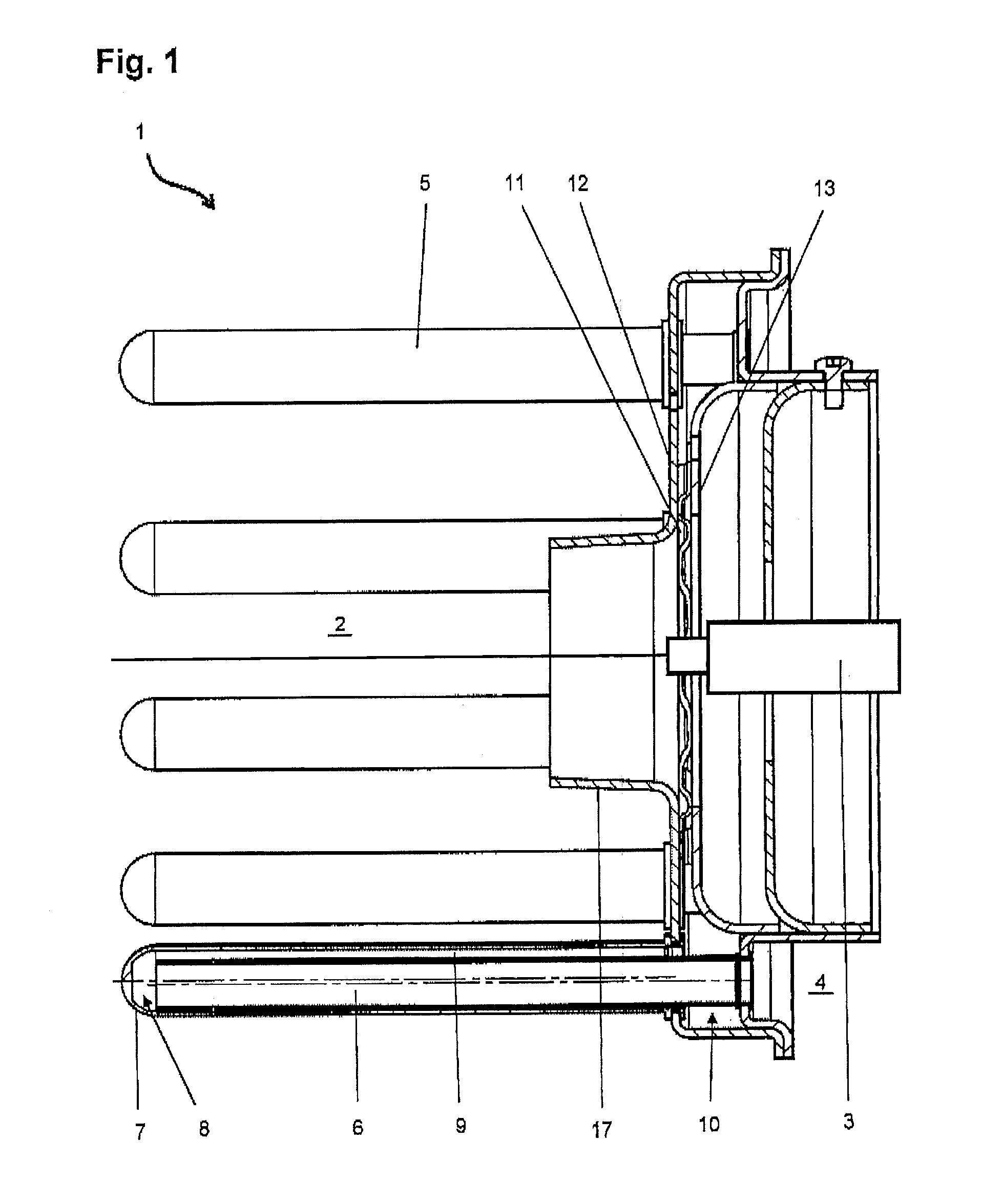

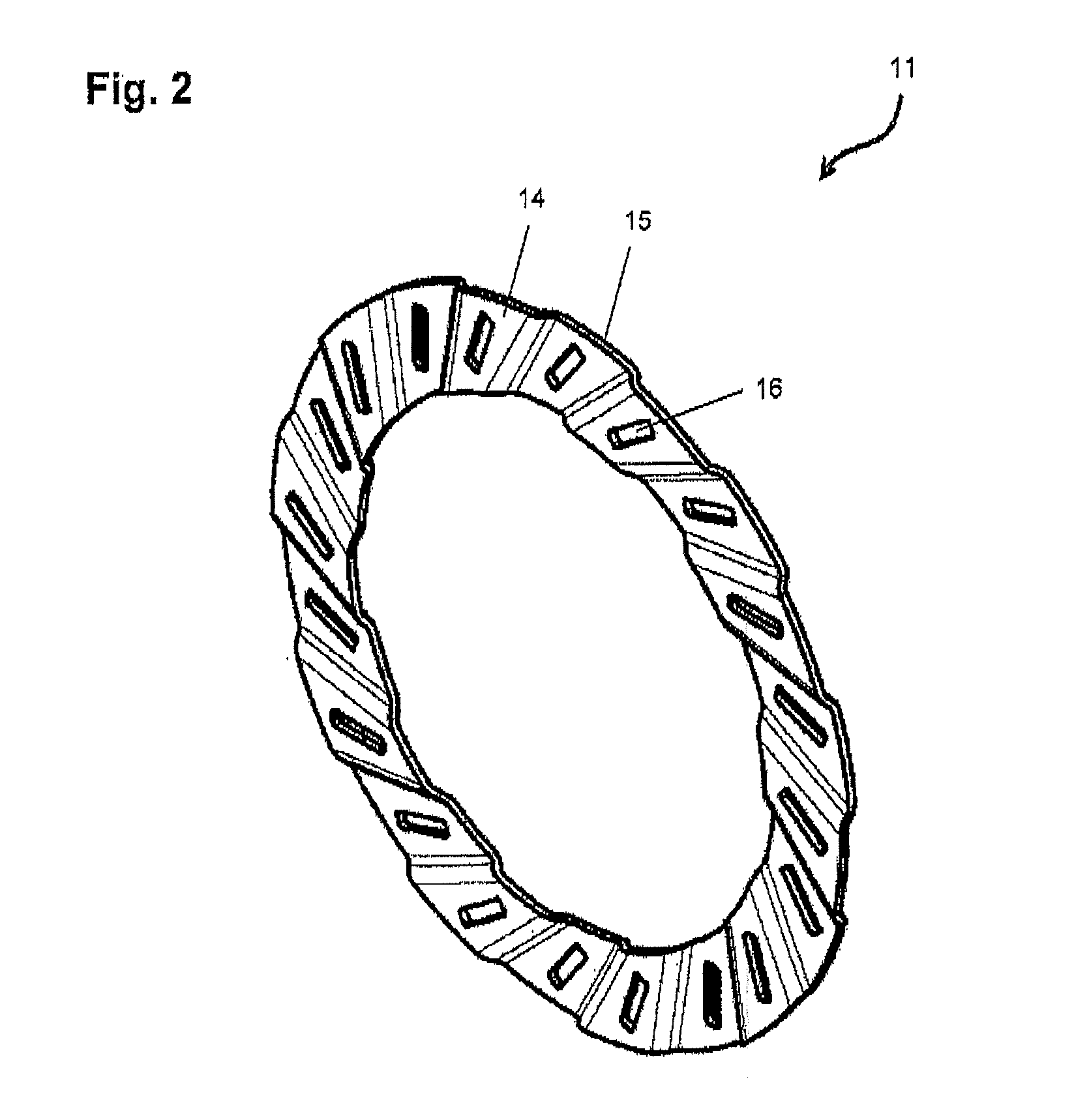

[0027]The oil premix burner is made up essentially of a combustion element 1, having a burner surface (not shown) on the outer lateral surface, a distribution chamber 2 below the burner surface, a central oil injection device 3, a combustion air channel 4 connected to a blower situated upstream as well as an air heat exchanger for the preheating of the combustion air in the area of the burner surface. The latter is made up of a plurality of double tube elements 5 that are distributed over the circumference, that extend with their axes parallel to combustion element 1 and have parallel flows through them, and having an inner tube 6 and an outer tube 7 having flows through them in series. In this context, each double tube element 5 is connected with the entry side of inner tube 6 to combustion air channel 4. The combustion air, in each case, in a turnaround zone 8 at the end face of the free end gets into annular space 9 that is formed between inner tube 6 and outer tube 7, and flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com