Infinitely adjustable coolant pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

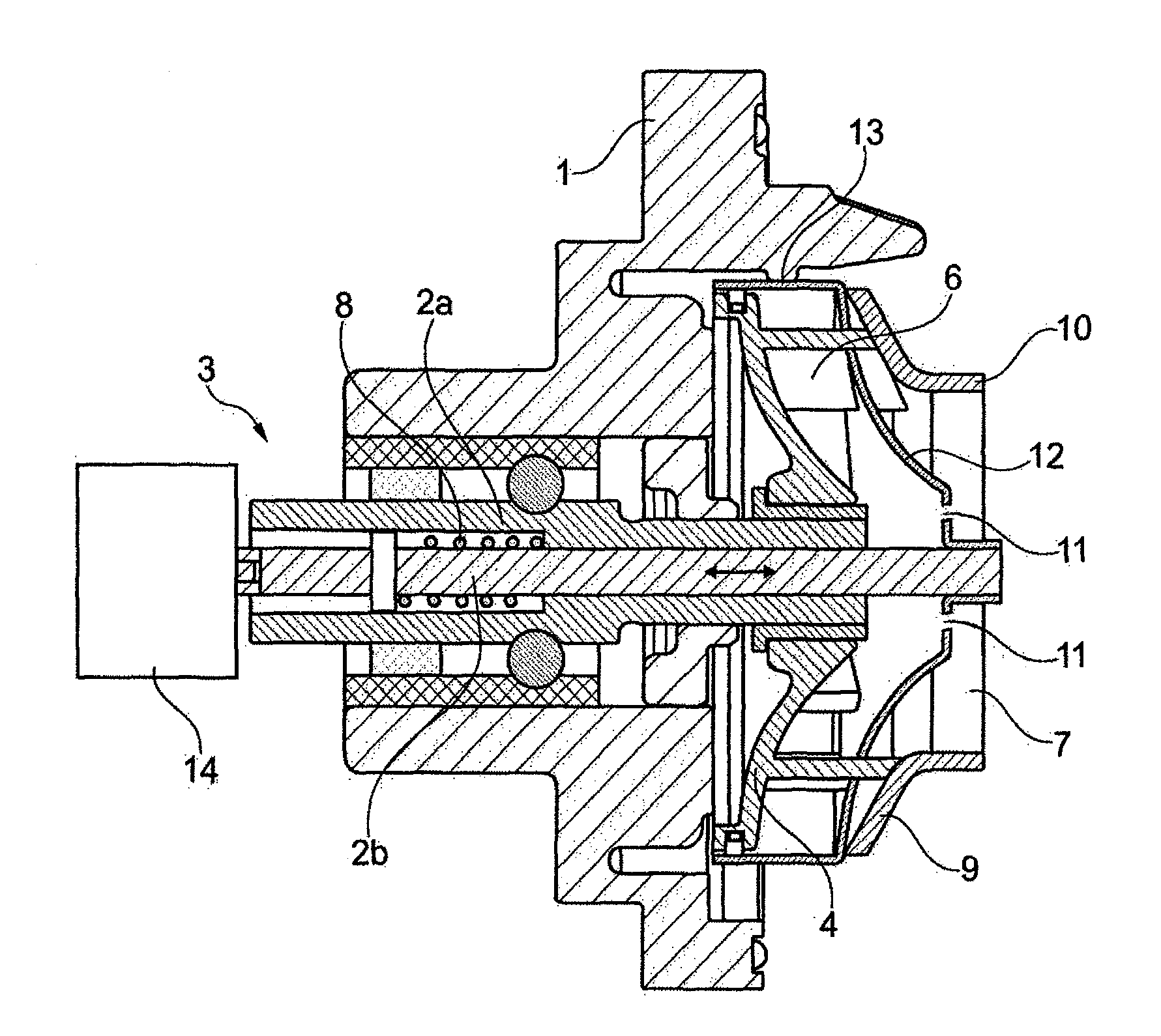

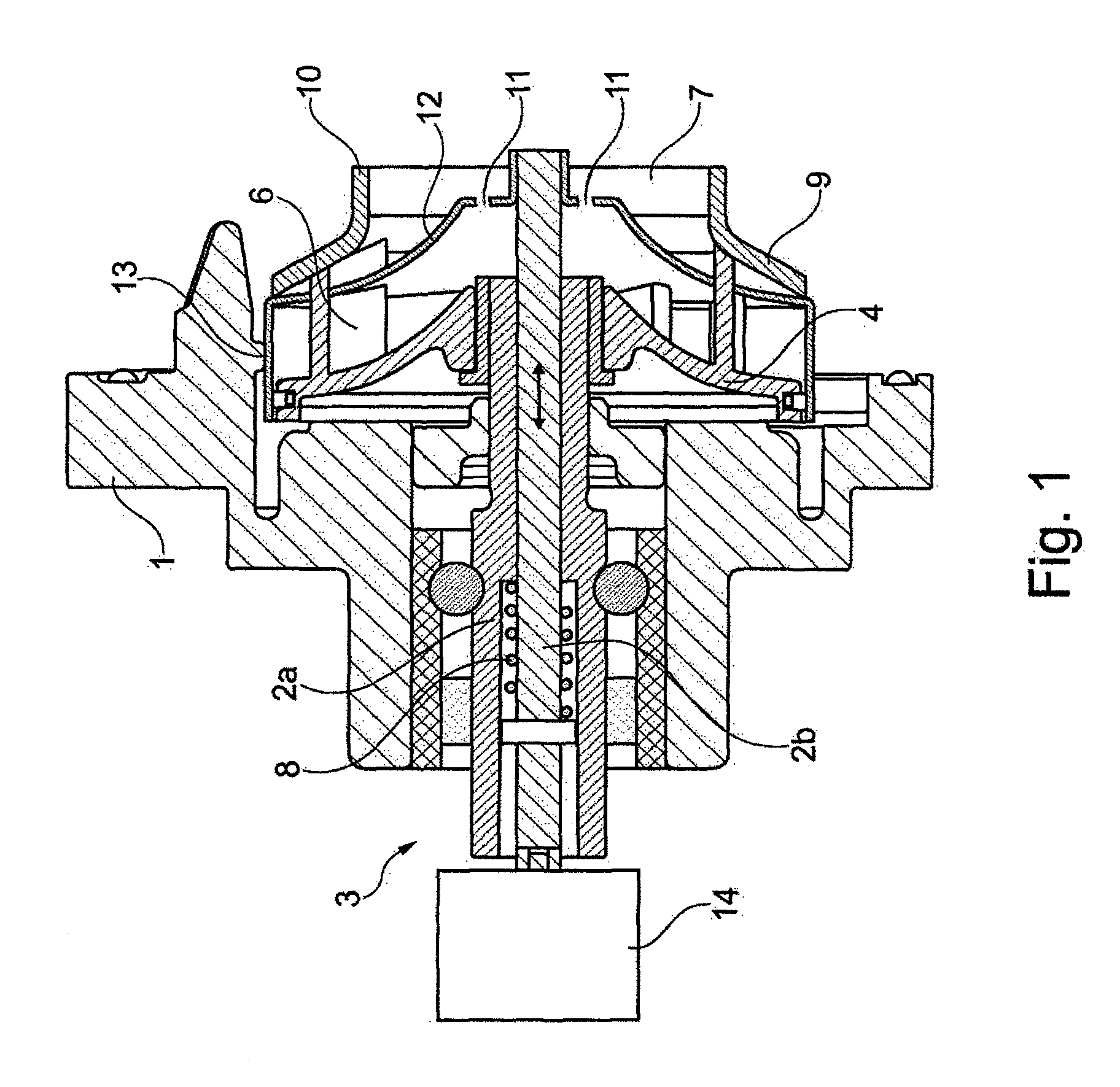

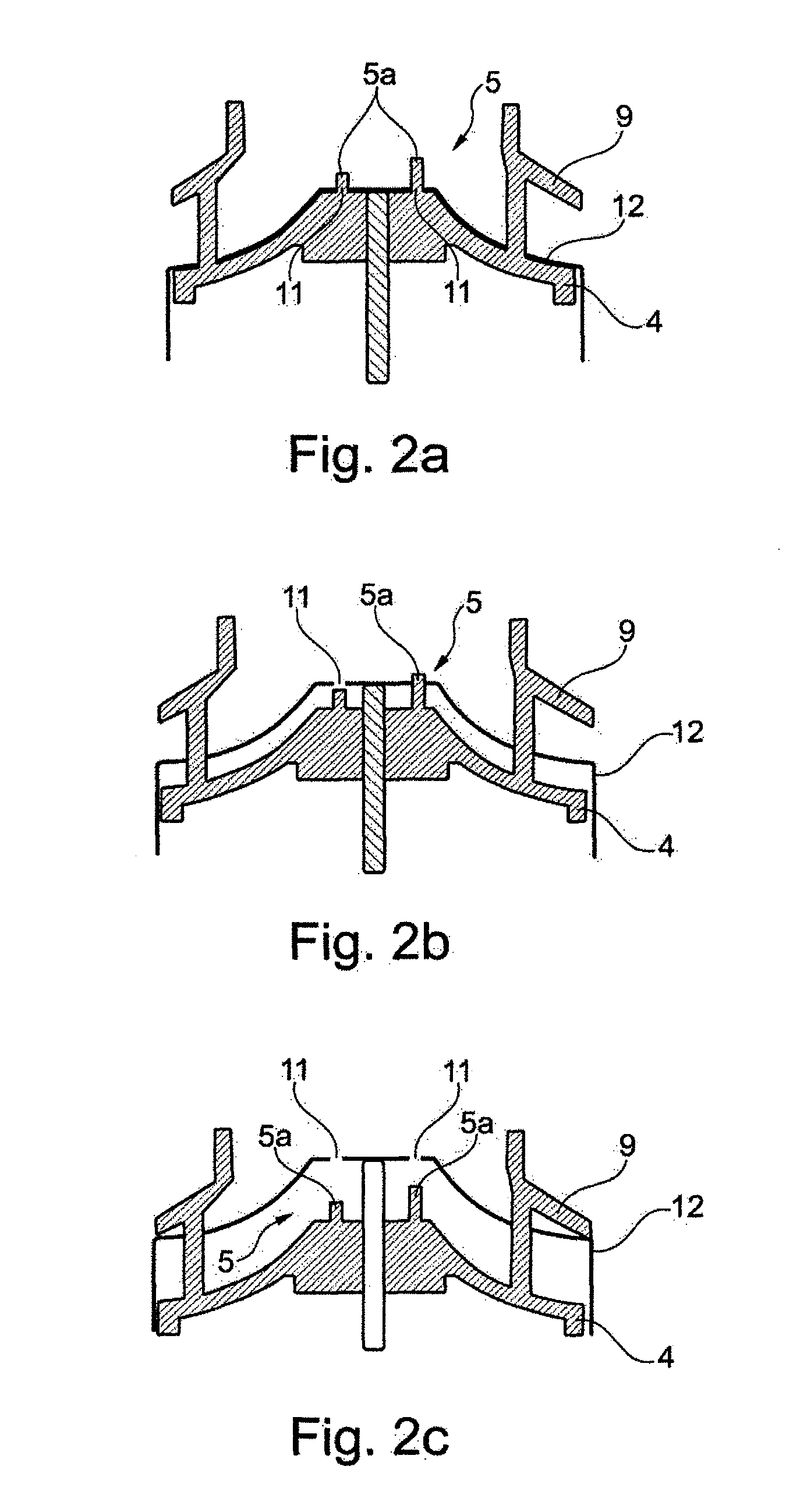

[0022]FIG. 1 shows a coolant pump for a coolant circuit of an internal combustion engine, the coolant pump having a pump housing 1, in which is mounted a drivable shaft 2a having an impeller 4 attached to one end thereof. Impeller 4 has vanes 6 extending into suction chamber 7. Impeller 4 and cover plate 9 are joined to one another. When impeller 4 rotates, fluid is conveyed into suction chamber 7 through an intake port 10 of pump housing 1. A guide plate 12, which is axially displaceable by an actuation unit 3, is disposed between impeller 4 and cover plate 9. Guide plate 12 has a contour corresponding to impeller 4 and a collar 13 oriented toward impeller 4. In order to achieve rapid heating of the internal combustion engine and to selectively adjust the engine temperature, the coolant pump must be controllable or switchable. To this end, a volume flow rate is adjusted in accordance with demand. In order to adjust the volume flow rate, guide plate 12 is axially displaced in pump h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com