Dual action bottle brush

a bottle brush and action technology, applied in the field of bottle brush assembly, can solve problems such as illness or infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

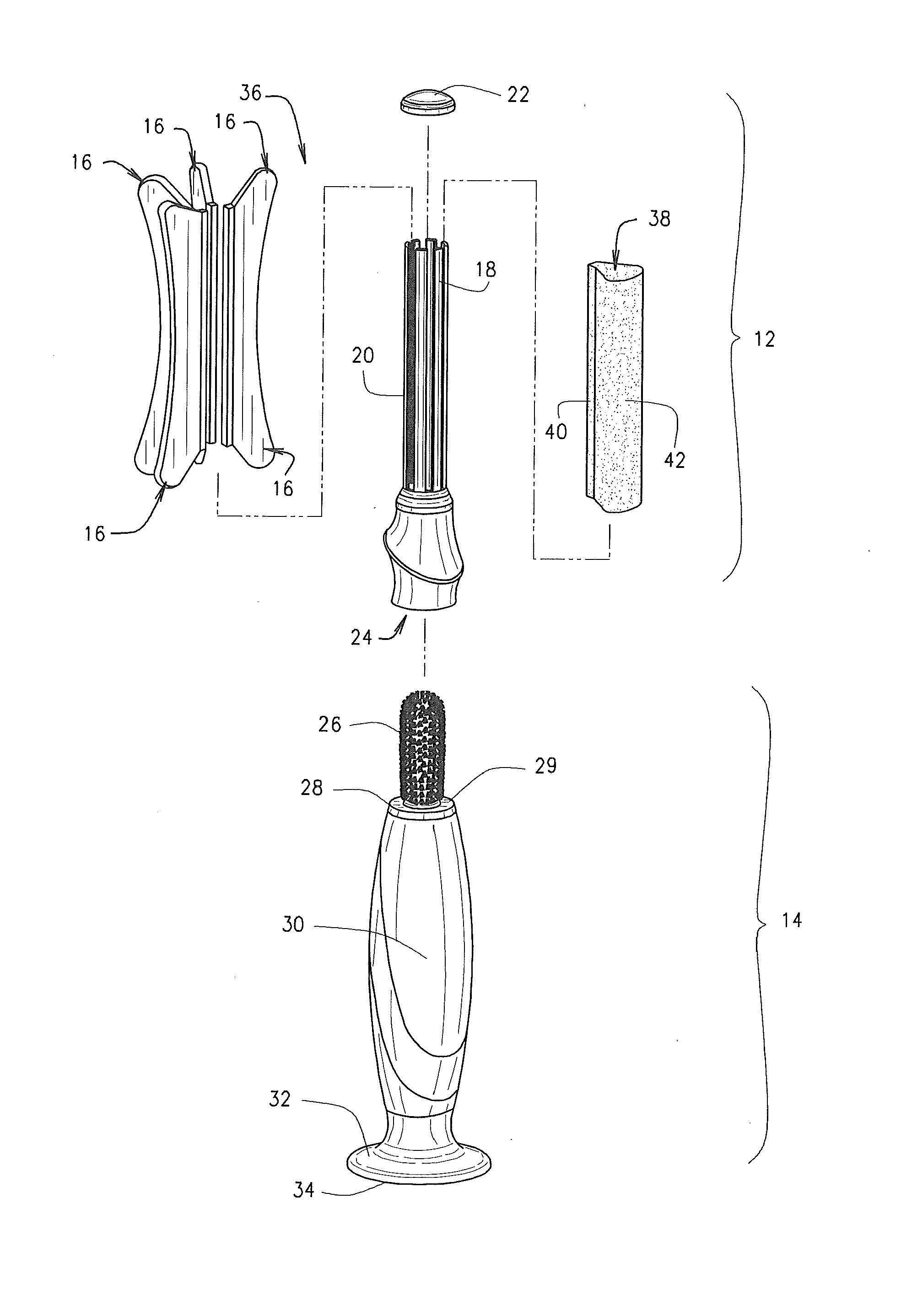

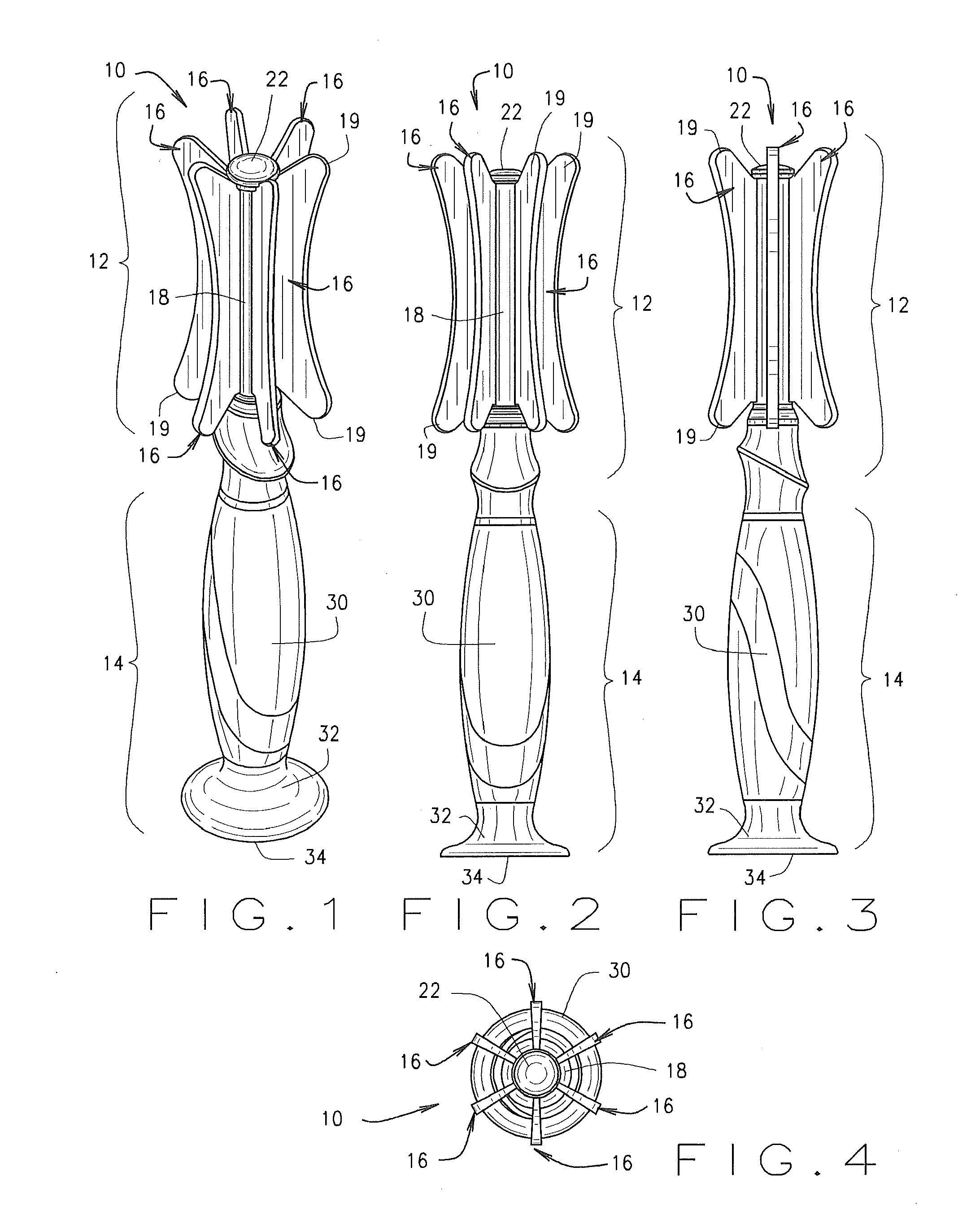

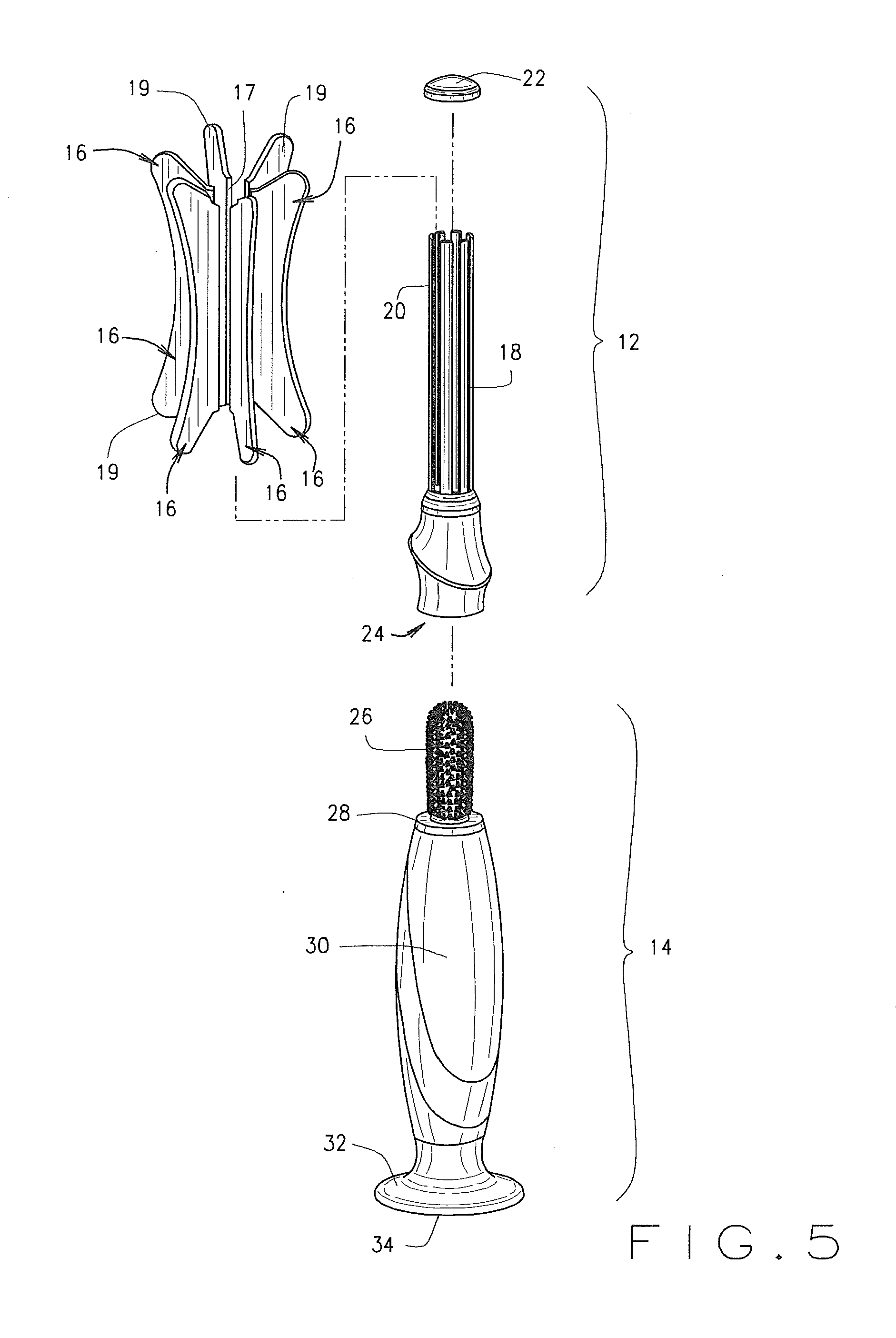

[0020]Referring now to the drawings more particularly by reference numbers, FIGS. 1-5 illustrate one embodiment of the brush assembly 10 constructed in accordance with the teachings of the present invention. The present brush assembly 10 is configured for cleaning and scrubbing the component parts of bottles including, but not limited to, baby bottles, baby bottle nipples, collars, caps, and other components. The brush assembly 10 may include a top brush portion 12 and a handle 14. The top brush portion 12 may include a plurality of petal shaped cleaning elements 16 attached to the outer surface 18 of the top brush portion 12 in a radial configuration. Each of the petal shaped elements 16 may be fixedly attached to the outer surface 18 of top brush portion 12 by any suitable means including engaging an edge portion of each petal shaped element 16 with a corresponding channel 20 (FIG. 5). In one embodiment, the cleaning elements 16 form the cleaning / scrubbing portion of the brush ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com