Pin based method of precision diamond turning to make prismatic mold and sheeting

a diamond turning and prismatic mold technology, applied in the field of pin based method of precision diamond turning to make prismatic molds and sheeting, can solve the problems of cost and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]A description of example embodiments follows.

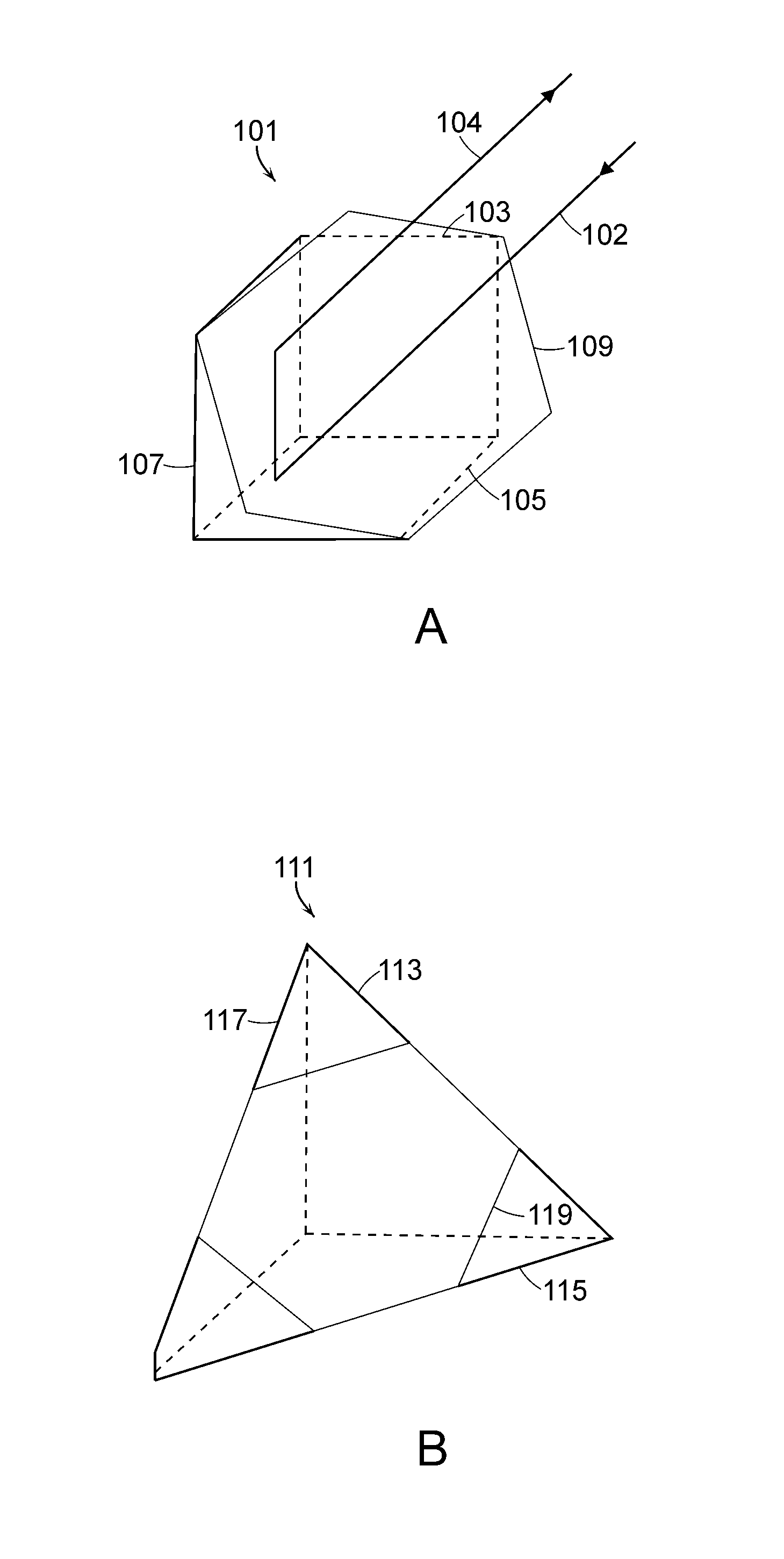

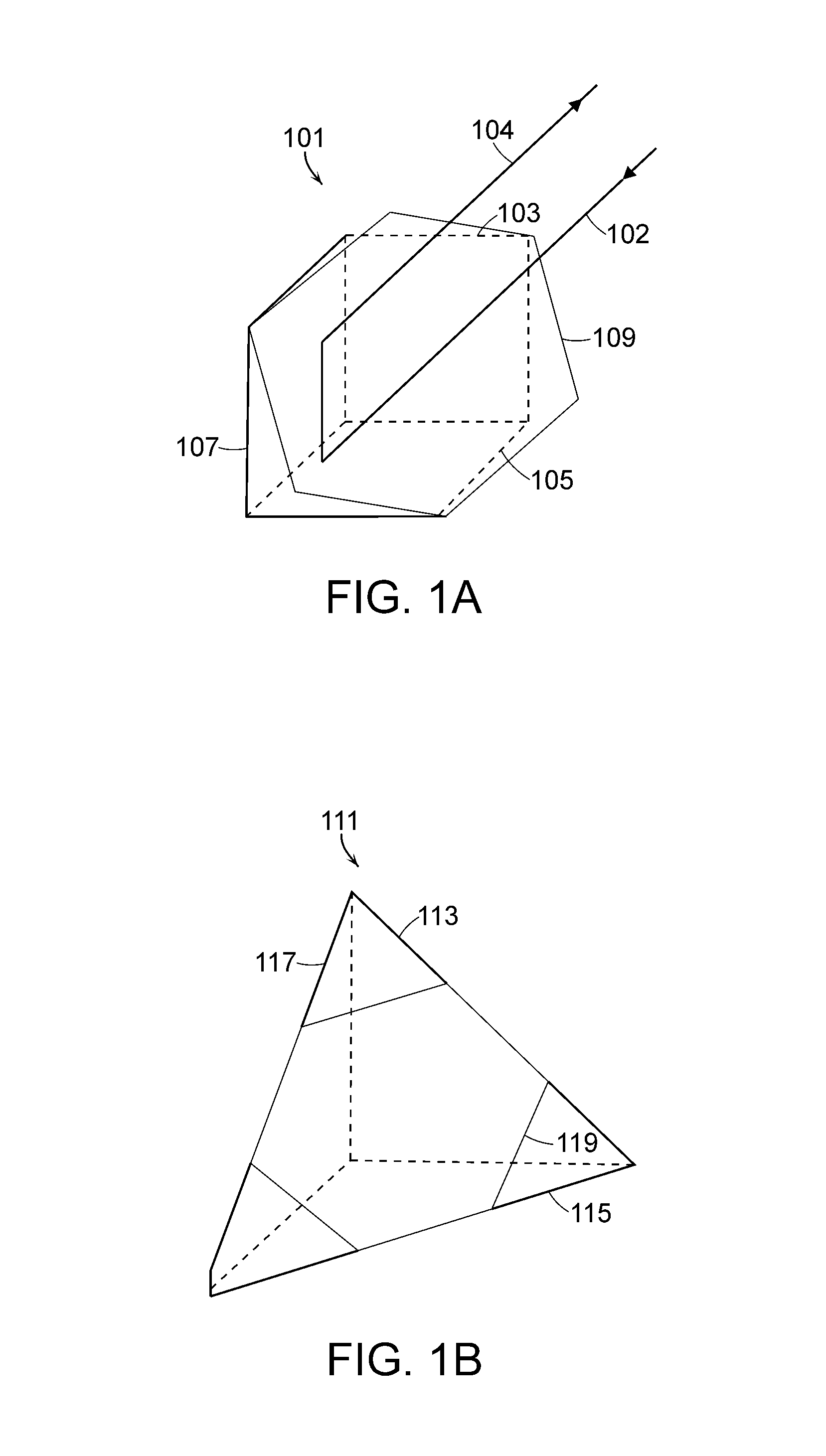

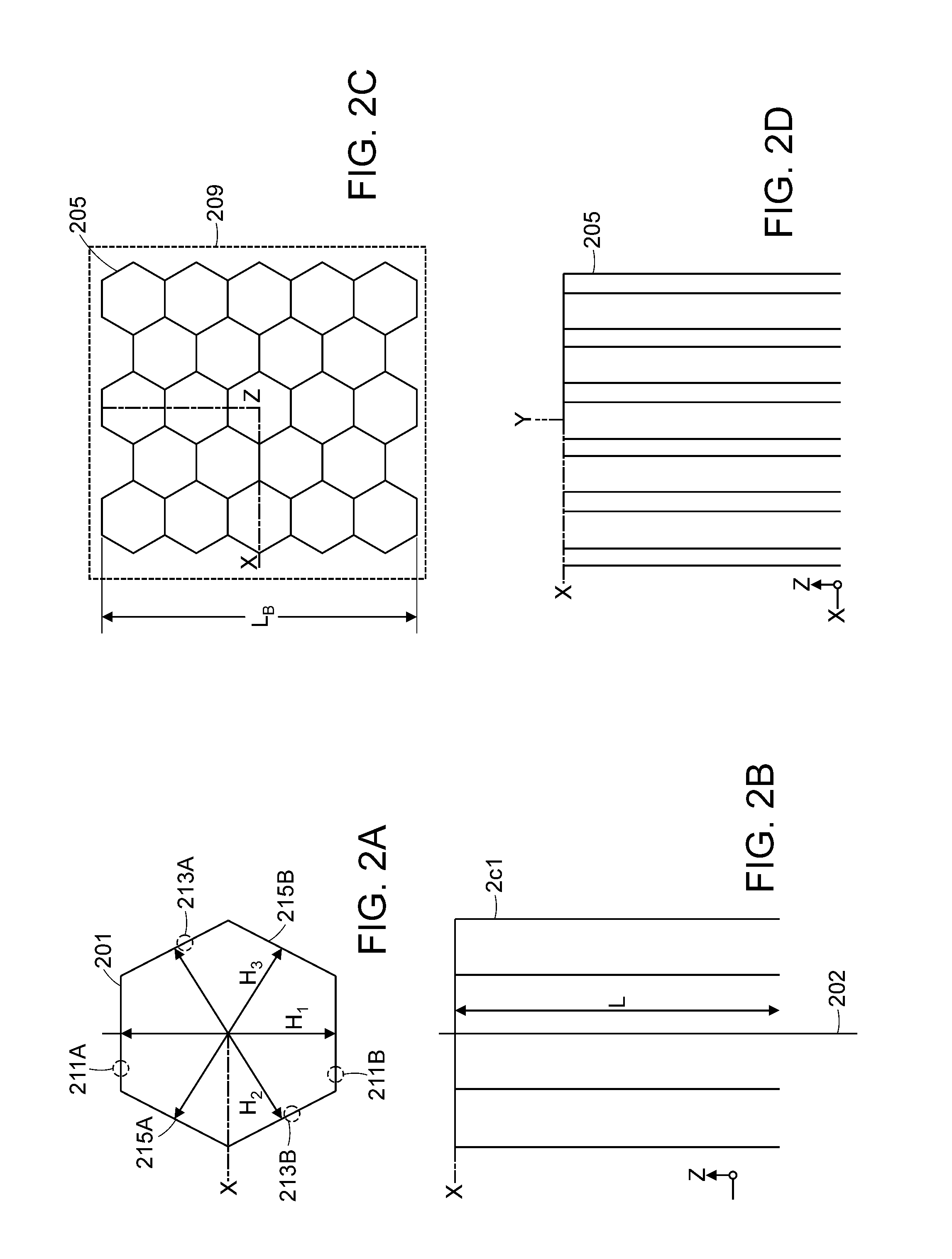

[0049]FIGS. 2-9 illustrate example embodiments for providing mass-producible hexagonal pins that may be used to provide a mold including a plurality of full cube corner corners. The mold may be used to form a retroreflective article with an optimal angle of entrance in the range of 0°-30°.

[0050]FIGS. 2A-2D are of top and side views of a hexagonal pin 201 and a hexagonal pin bundle 205, respectively. Each hexagonal pin includes a hexagonal cross section and a hexagonal aperture. In the illustrated example, the hexagonal pin 201 features a cross sectional height H of 0.010 inches along the vertical or z-axis, and a length L of 1 inch. A reference axis 202 depicted in FIG. 2B is parallel to all six side surfaces of the hexagonal pin, and is also through the center point of the hexagon shown in FIG. 2A.

[0051]The hexagon cross section includes three pairs of parallel sides. One parallel side pair 211A and 211B is positioned in a horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| center angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| entrance angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com